Continuous tubular preparation method for long-chain alkyl modified silicone oil

A long-chain alkyl and modified silicon technology, which is applied in the field of preparing modified silicone oil, can solve the problems of low production efficiency and difficult control of batch-to-batch stability, and achieve high production efficiency, easy control of reaction heat, and safe production good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

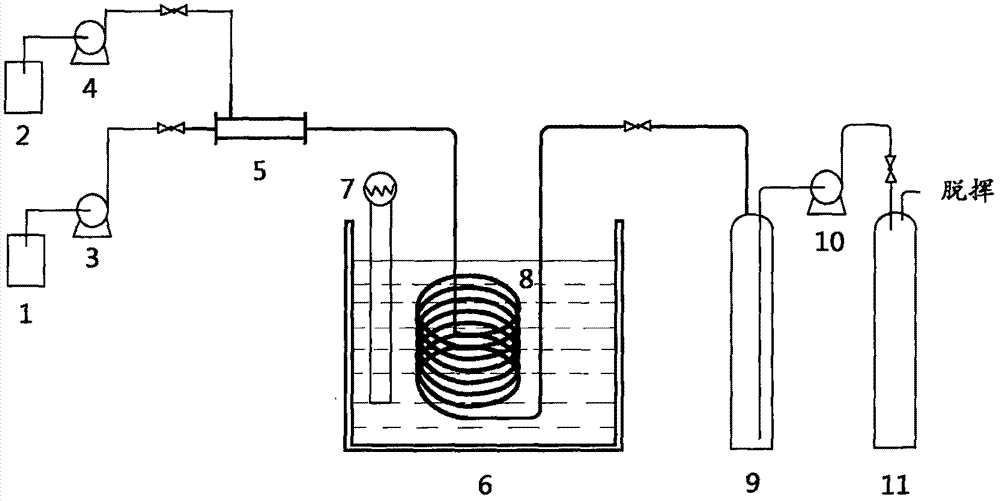

Embodiment 1

[0038] Mix α-dodecene (>98%) and low-hydrogen silicone oil (TH-201, hydrogen content 0.5%, 100cs) according to the mass ratio of 1:1 and add them to the first storage tank 1, and then pass through the second A metering pump 3 enters the mixed material into the static mixer 5 according to the flow rate of 30ml / min; the platinum catalyst (Shin-Etsu ACS-Pt-50) is diluted to 50ppm with ethanol and then added to the second storage tank 2, and then passed through the second The metering pump 4 enters the static mixer 5 at a flow rate of 1 ml / min. The mixed material enters the coil 8 in the oil bath tank 6 from the static mixer 5. The length of the coil is 5m, the inner diameter is 3mm, and the wall thickness is 1mm. The temperature of the oil bath is controlled at 110°C by the mold temperature controller 7. The material enters the third storage tank 9 from the coil reactor 8, and a part of the reactant is transported to the devolatilization kettle 11 through the third metering pump ...

Embodiment 2

[0040] Mix α-dodecene (>98%), styrene (>99%) and high hydrogen-containing silicone oil (Dow Corning MHX-1107, 30cs) according to the mass ratio of 6:1:3 and add them to the first storage tank 1 In, then through the first metering pump 3, the mixed material enters the static mixer 5 according to the flow rate of 200ml / min; the platinum catalyst (Shin-Etsu ACS-Pt-50) is diluted to 50ppm with styrene and then added to the second storage tank 2 , and then enter the static mixer 5 through the second metering pump 4 according to the flow rate of 8ml / min. The mixed material enters the coil 8 in the oil bath tank 6 from the static mixer 5. The length of the coil is 4m, the inner diameter is 5mm, and the wall thickness is 1mm. The temperature of the oil bath is controlled at 120°C by the mold temperature controller 7. The material enters the third storage tank 9 from the coil reactor 8, and a part of the reactant is transported to the devolatilization kettle 11 through the third meteri...

Embodiment 3

[0042] Mix α-octene (>98%), α-methylstyrene (>99%) and high hydrogen-containing silicone oil (Shin-Etsu KF-99, 30cs) according to the mass ratio of 4:1:3 and add them to the first In the storage tank 1, then the mixed material is entered into the static mixer 5 according to the flow rate of 1L / min through the metering pump 3; the platinum catalyst (1% chloroplatinic acid-isopropanol solution) is diluted to 50ppm with styrene and then added to the In the second storage tank 2, then enter the static mixer 5 according to the flow rate of 50ml / min through the second metering pump 4. The mixed material enters the coil 8 in the oil bath tank 6 from the static mixer 5. The length of the coil is 5m, the inner diameter is 8mm, and the wall thickness is 2mm. The temperature of the oil bath is controlled at 130°C by the mold temperature controller 7. The material enters the third storage tank 9 from the coil reactor 8, and a part of the reactant is transported to the devolatilization ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com