Antibacterial aluminum and manufacturing method thereof

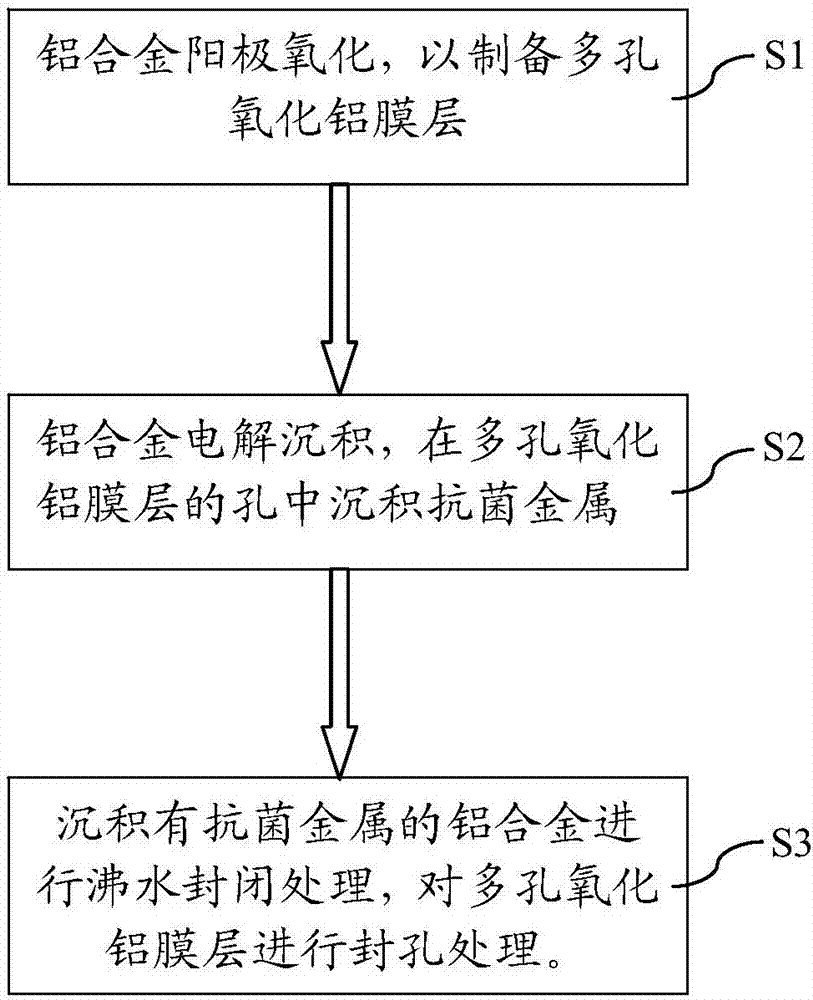

A manufacturing method and technology of antibacterial aluminum, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of loss of bacterial performance, precipitation of electrolytic deposition solution, poor antibacterial durability, etc., to improve corrosion resistance, Inexpensive to manufacture, long lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

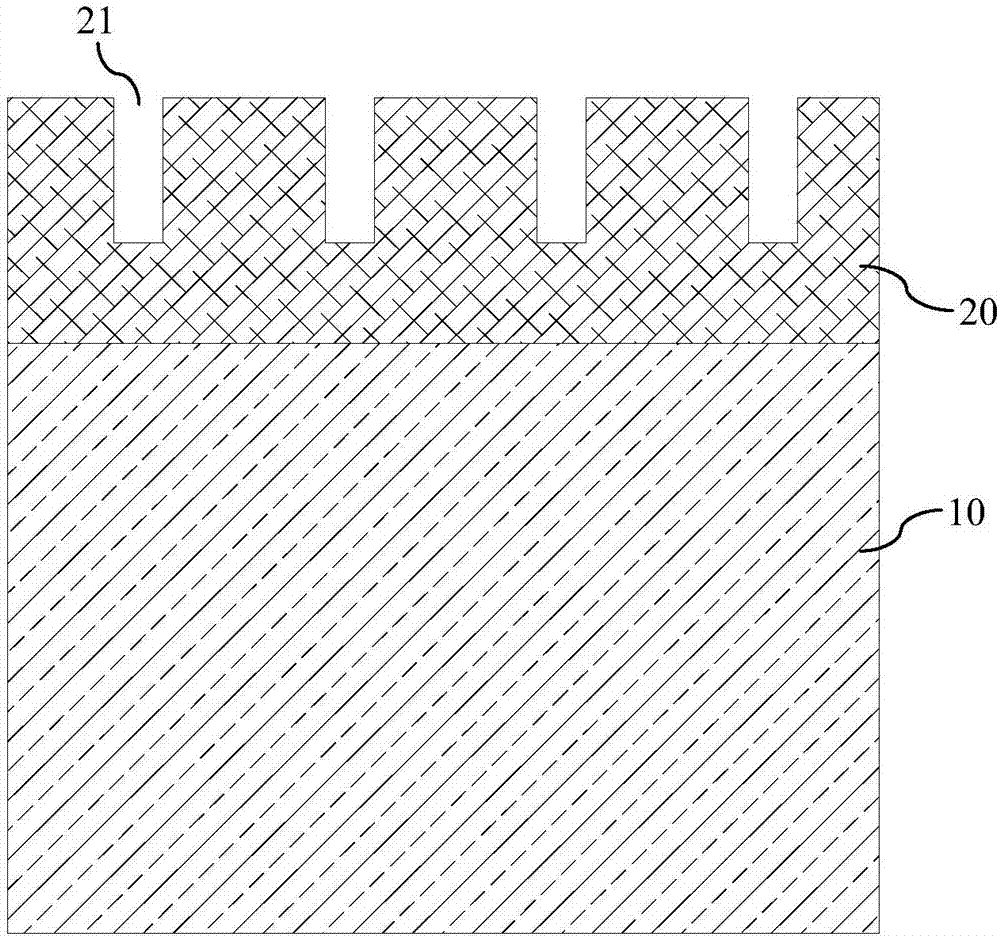

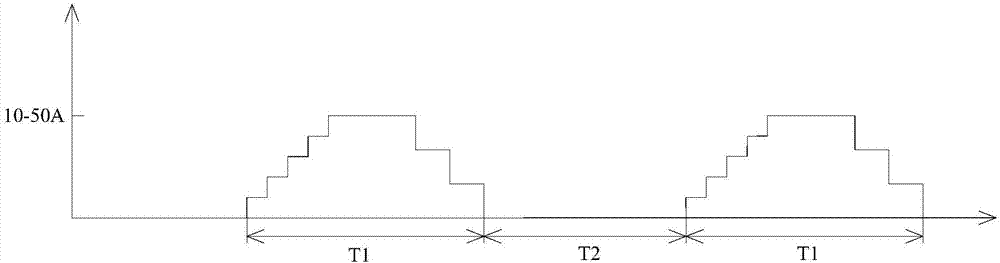

[0054] First, the aluminum alloy pretreated by degreasing, oxide film removal, ash removal, and water washing is used as the anode, graphite, aluminum or lead, etc. are used as the cathode, and DC anodization is performed in the electrolyte to prepare the aluminum alloy with porous aluminum oxide film. . Then, the obtained aluminum alloy with porous aluminum oxide film and graphite, aluminum, lead or stainless steel are combined to form two electrodes, at 7-25g / L silver nitrate, 1.5-5g / L patina, 5-30g / L ten Electrodeposition is carried out in the deposition solution of hydromagnesium sulfate (MgSO4·10H2O), 2-10g / L of complexing agent, the conditions of electrolytic deposition are: temperature 5℃-35℃, AC / DC (AC / DC) 5-30V, Electrodeposition time is 3-30min. After the deposition is completed, the aluminum alloy is taken out, washed with water, and immersed in clean water to remove the electrolyte on the surface, and hot water sealing treatment is performed to obtain an antibacter...

Embodiment 2

[0060] First, the aluminum alloy pretreated by degreasing, oxide film removal, ash removal, and water washing is used as the anode, graphite, aluminum or lead, etc. are used as the cathode, and DC anodization is performed in the electrolyte to prepare the aluminum alloy with porous aluminum oxide film. . Then, the obtained aluminum alloy with porous aluminum oxide film and graphite, aluminum, lead or stainless steel are combined to form two electrodes, at 7-25g / L silver nitrate, 1.5-5g / L patina, 5-30g / L ten Electrodeposition is carried out in the deposition solution of hydromagnesium sulfate (MgSO4·10H2O), 2-10g / L of complexing agent, the conditions of electrolytic deposition are: temperature 5℃-35℃, AC / DC (AC / DC) 5-30V, Electrodeposition time is 3-30min. After the deposition is completed, the aluminum alloy is taken out, washed with water, and immersed in clean water to remove the electrolyte on the surface, and hot water sealing treatment is performed to obtain an antibacter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com