Device for mixed injection of fiber airflows

A technology of mixed spraying and air flow, which is applied in the field of fiber textiles, can solve the problems of heavy conveying air duct, flying flowers, poor mixing degree, etc., and achieve the effects of saving manpower and working hours, simplifying cleaning work, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

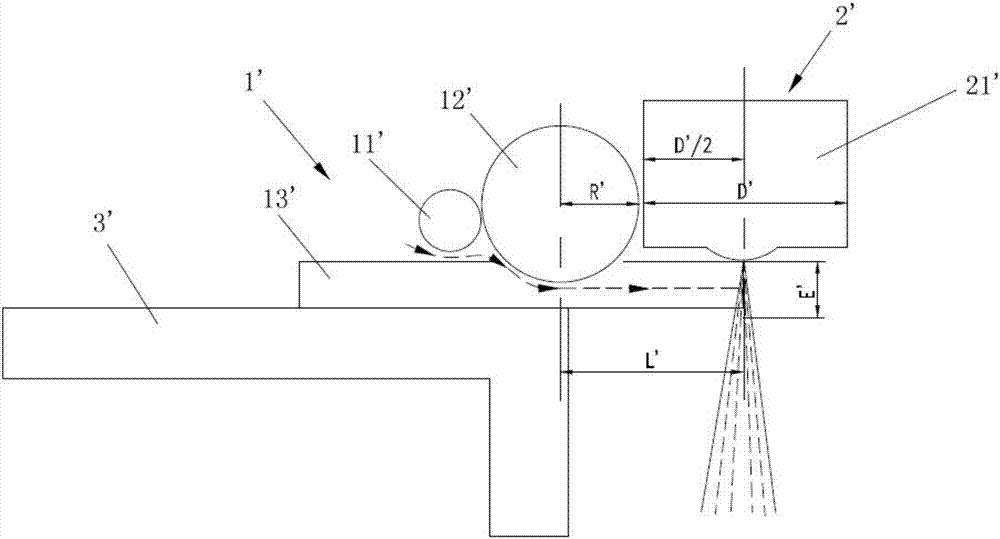

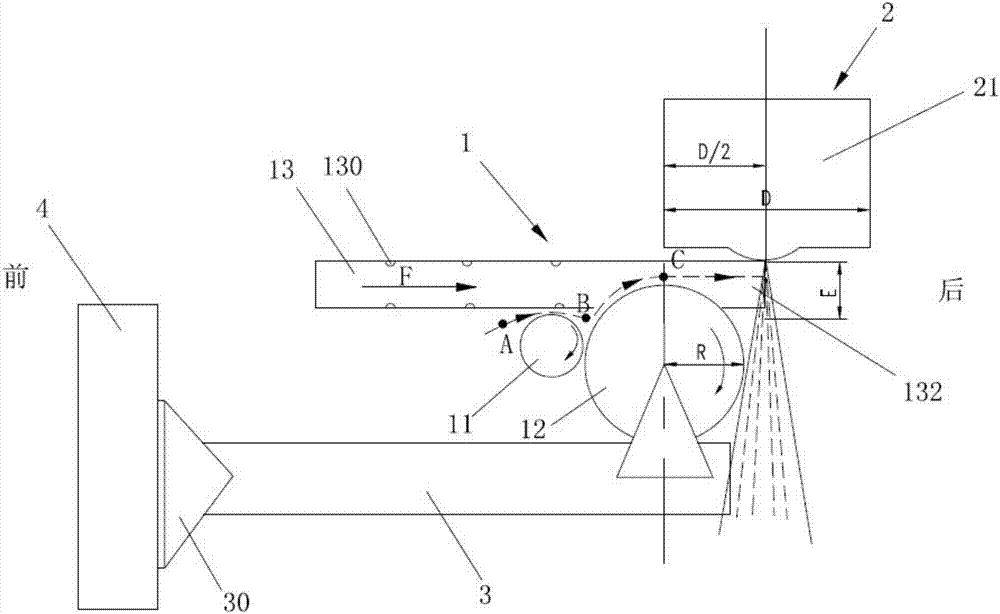

[0024] Such as figure 2 As shown, the fiber air flow mixing spraying device of the preferred embodiment of the present invention includes a supply device 1 for fiber materials to be mixed, a melt blowing device 2 , and a support 3 .

[0025] The fiber material supply device 1 to be mixed includes a first roller (doffer) 11 , a second roller (cylinder) 12 , and a conveying air duct 13 . The fiber material supply device 1 to be mixed is installed on the support 3, and the first roller 11 and the second roller 12 can rotate around their respective central axes relative to the support 3, and the rotation direction of both is the same. The diameter of the first roller 11 is smaller than that of the second roller 12 , the two are close to each other but not in contact with each other, and are arranged side by side under the conveying air duct 13 .

[0026] The feeding air duct 13 is composed of four sides, up, down, left, and right, forming a material inlet 131 and a material outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com