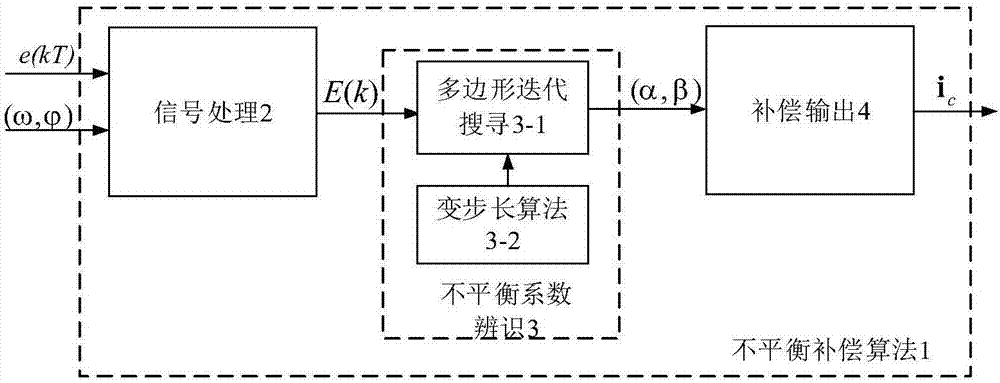

Unbalanced compensation algorithm of polygonal iterative search with variable step size for rotor imbalance coefficient

A rotor unbalance and balance compensation technology, applied in the field of compensation algorithm, can solve problems such as unbalance vibration control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

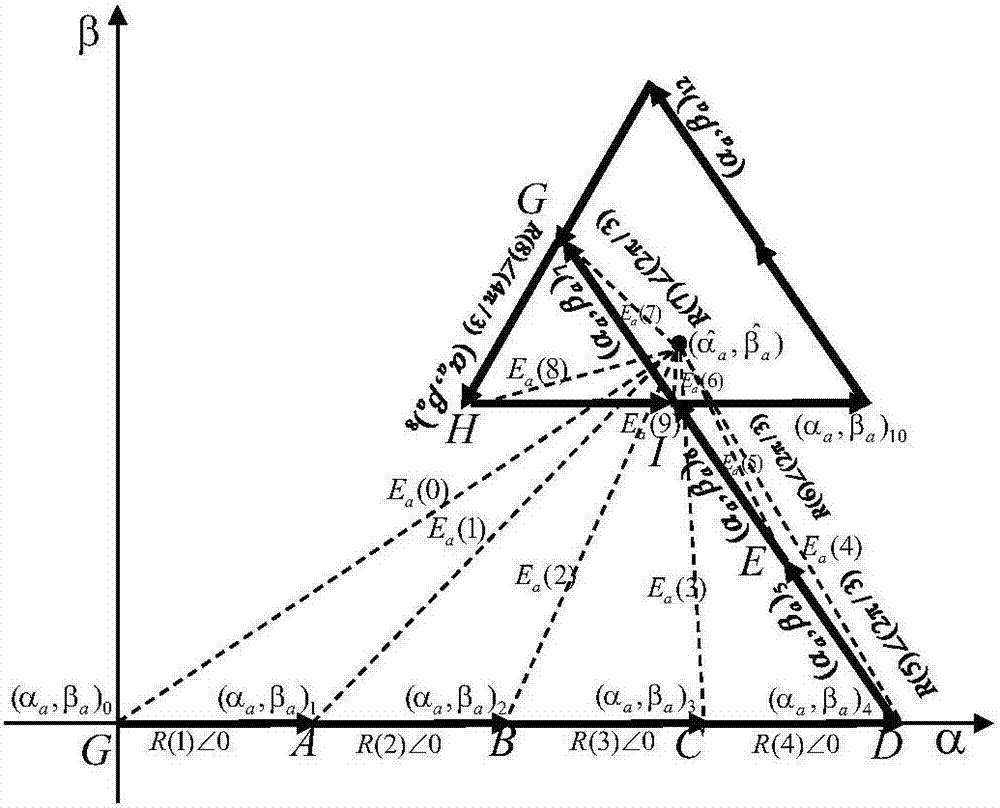

Method used

Image

Examples

Embodiment Construction

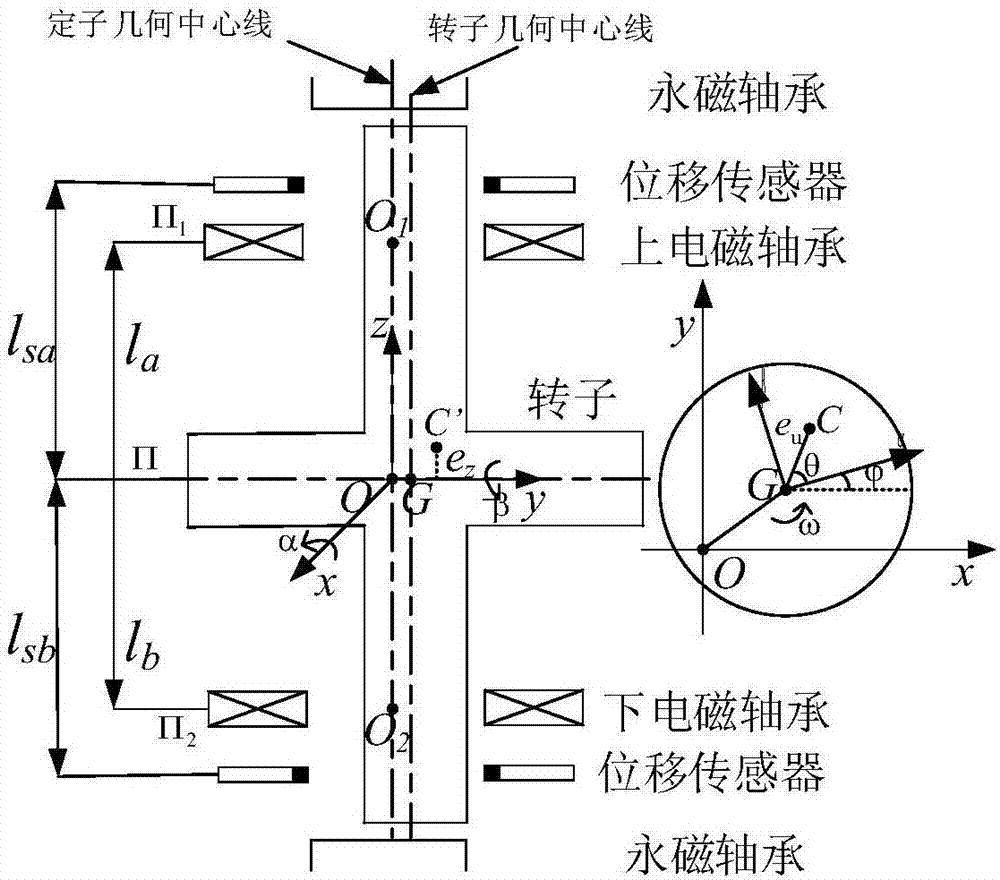

[0067] Taking the active electromagnetic bearing-rigid rotor system as an example, an unbalance compensation algorithm for rotor unbalance coefficient variable step size polygon iterative search will be described in detail below.

[0068] The active electromagnetic bearing-rigid rotor system used in this embodiment is as follows: figure 2 shown.

[0069] The axial direction of the rotor is supported by a pair of upper and lower permanent magnetic bearings, and the radial direction is respectively supported by the upper and lower electromagnetic bearings. The displacement of the rotor is measured by a non-contact displacement sensor located near the upper and lower electromagnetic bearings.

[0070] like figure 2 , firstly, the plane where the upper electromagnetic bearing and the lower electromagnetic bearing are located can be defined as Π 1 and Π 2 , the geometric centers of the upper and lower magnetic bearing journals are located at Π 1 and Π 2 inside, denoted as O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com