Correction method and system for surface mounting machine importing production data

A technology for producing data and correcting methods, applied in data processing applications, electrical digital data processing, special data processing applications, etc., can solve the problems of inappropriate solder paste layer data, production quality defects, and excessive printing solder paste, etc., to reduce The use of human resources, the reduction of production defects, the effect of improving machine utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

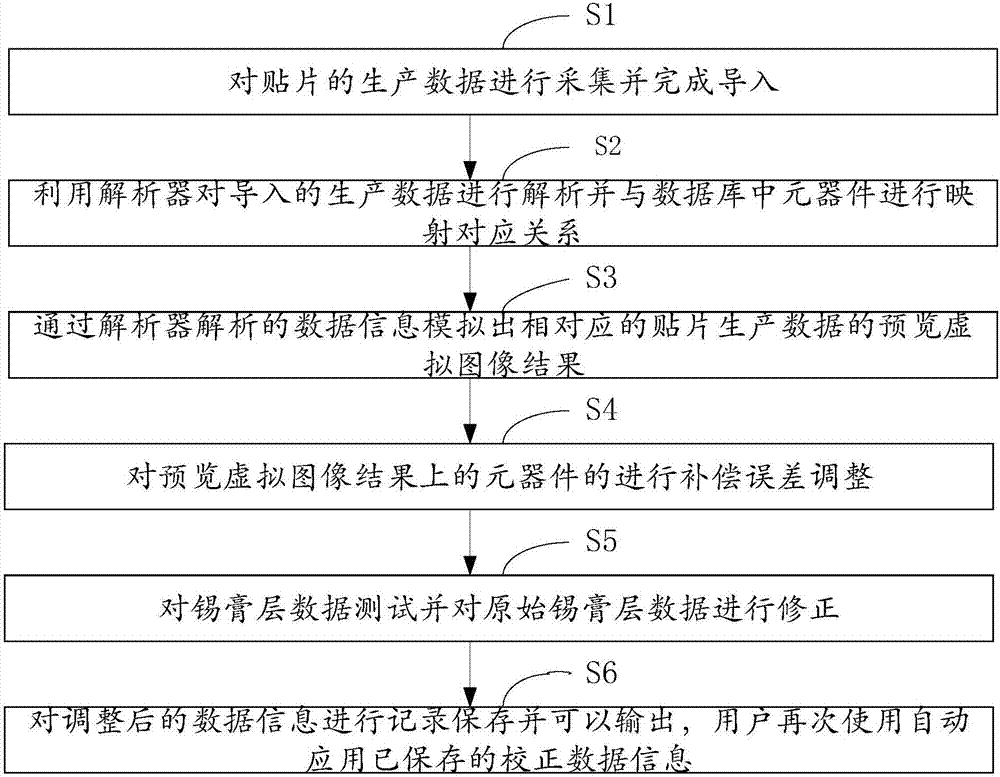

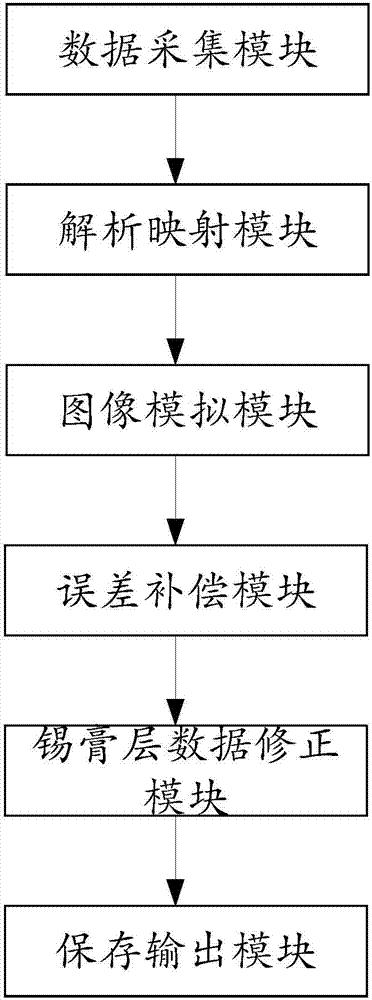

[0040] figure 1 It shows the flow chart of the method for correcting the placement machine importing production data provided by the present invention, which is described in detail as follows:

[0041] Step S1, collect and import the production data of the patch; let the user submit the necessary production data, and import the production data into the simulation software. The production data includes bill of materials, component coordinates and PCB board data information. The user submits the corresponding file on the software, then uploads it, and the system analyzes it.

[0042] Step S2, using the parser to parse the imported production data and map the corresponding relationship with the components in the database; in the gerber (PCB production data) parser, generate a corresponding simulated pcb image.

[0043] In coordinate file parsing, the data of different software manufacturers and different formats are parsed into unified internal format data.

[0044] In the bom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com