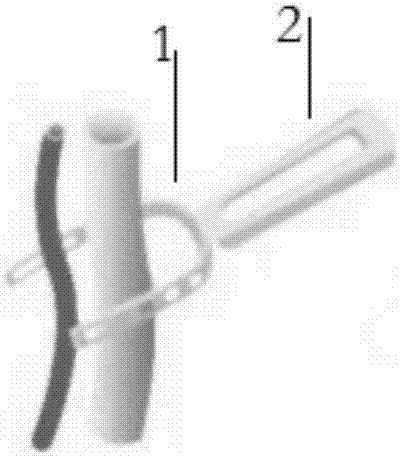

Quickly-absorbed hemostatic ligating clip

A ligation clip and fast technology, which is applied in the fields of coating, medical science, surgery, etc., can solve the problems of not being able to apply clipping first and then separating after acute bleeding, requiring high technical proficiency of the operator, and not being able to close normally, so as to avoid Tissue irritation and foreign body reaction, facilitates degradation and absorption, and prevents pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Glycolide-carbonate copolymer material preparation:

[0027] 191 grams of polymer grade glycolide and 9 grams of cyclocarbonate were placed in a reactor, 0.02% of stannous octoate catalyst was added, and the reaction was carried out at 120° C. for 10 hours under high vacuum conditions. Take it out, crush it into granules, dry the above granules in vacuum at 50° C. for 24 hours, weigh 185 grams, and the yield is 92.5%. Using hexafluoroisopropanol as a solvent, the intrinsic viscosity of the glycolide-carbonate copolymer was measured to be 4.36dl / g with an Ubbelohde viscometer in a constant temperature water bath at 25°C.

[0028] The glycolide-carbonate copolymer was measured, and the glycolide unit accounted for 95.1%.

[0029] Preparation of degradation solution: refer to the standard of ISO13781:1997 to prepare Sorensen buffer solution with a pH value of 7.4±0.2.

[0030] The material was degraded in Sorensen's buffer solution in vitro for 16 weeks, and lost more th...

Embodiment 2

[0036] Glycolide-carbonate copolymer material preparation:

[0037] 106 grams of polymer grade glycolide and 94 grams of cyclocarbonate were placed in a reactor, 0.02% of stannous octoate catalyst was added, and the reaction was carried out at 130° C. for 24 hours under vacuum conditions. Take it out, crush it into granules, dry the above granules in vacuum at 50° C. for 24 hours, weigh 178 grams, and the yield is 89%. Using hexafluoroisopropanol as a solvent, the intrinsic viscosity of the glycolide-carbonate copolymer was measured to be 2.68dl / g with an Ubbelohde viscometer in a constant temperature water bath at 25°C.

[0038] Glycolide-carbonate copolymer was measured, and the glycolide unit accounted for 50.2%.

[0039] The material was degraded in Sorensen's buffer solution in vitro for 26 weeks, and lost more than 60% of its weight.

[0040] Processing of absorbable hemostatic ligation clip:

[0041] The glycolide-carbonate copolymer synthesized above is processed in...

Embodiment 3

[0043] Glycolide-carbonate copolymer material preparation:

[0044] 145 grams of polymer grade glycolide and 55 grams of cyclocarbonate were placed in a reactor, 0.02% stannous octoate catalyst was added, and the reaction was carried out at 120° C. for 20 hours under vacuum conditions. Take it out, crush it into granules, dry the above granules in vacuum at 50° C. for 24 hours, weigh 180 grams, and the yield is 90%. Using hexafluoroisopropanol as a solvent, the intrinsic viscosity of the glycolide-carbonate copolymer was measured to be 3.14dl / g with an Ubbelohde viscometer in a constant temperature water bath at 25°C.

[0045] The glycolide-carbonate copolymer was measured, and the glycolide unit accounted for 70.1%.

[0046] The material is degraded in Sorensen's buffer solution in vitro for 24 weeks, and its weight loss exceeds 60%.

[0047] Processing of absorbable hemostatic ligation clip:

[0048] The glycolide-carbonate copolymer synthesized above is processed into an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com