A Cold Extrusion Overflow Forming Process for Oil Pump Cover Plate

A forming process, oil pump cover technology, applied in metal processing equipment, mechanical equipment, engine components, etc., can solve the problems of expensive intermediate processing costs, unstable mold life, complex forming process, etc., to relax the weight requirements, save softening Lubrication treatment, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

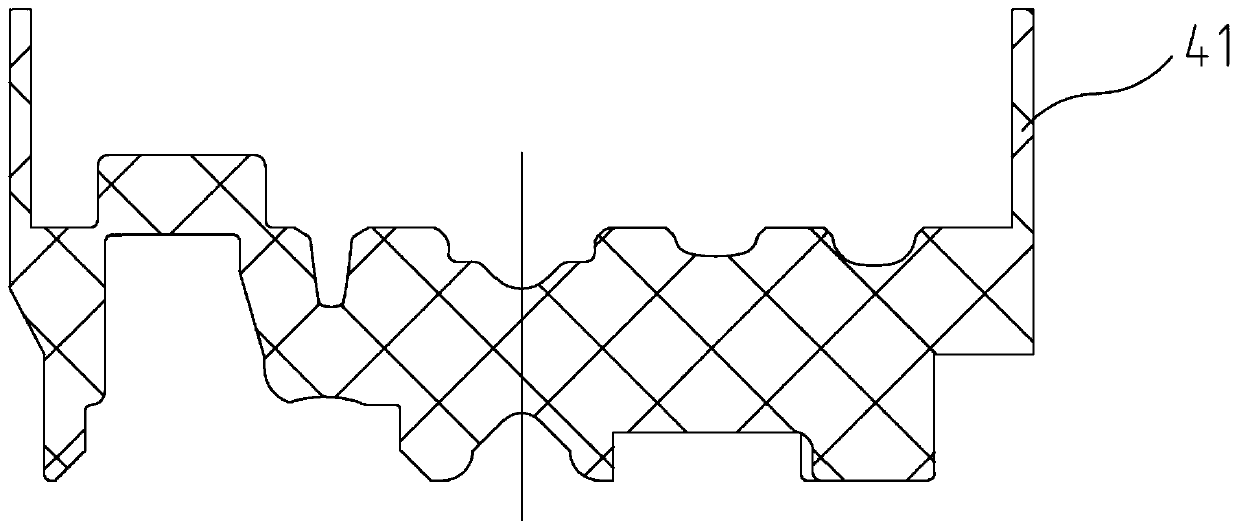

[0037] The front and back of the cover plate of the oil pump involved in the present invention are both irregular-shaped, wherein there are two circles of asymmetrical oil grooves on the front, and special-shaped deep grooves on the reverse, and the depth of the special-shaped deep grooves exceeds that of the front.

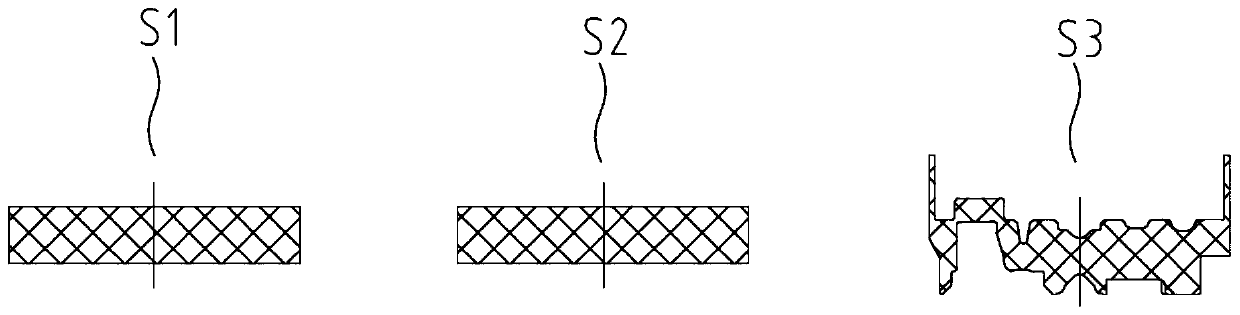

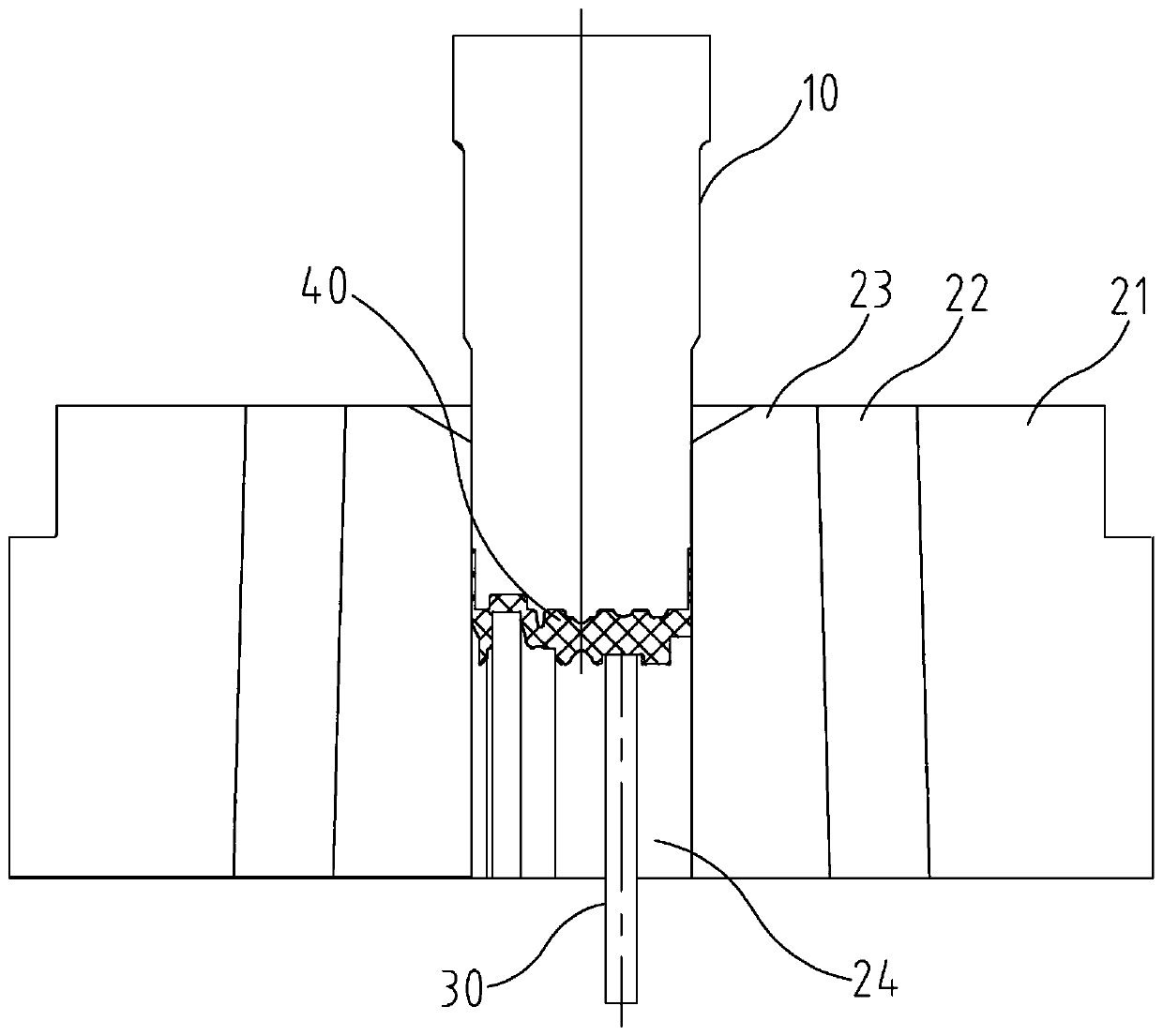

[0038] like figure 1 As shown, the cold extrusion overflow forming process of the oil pump cover plate of the present invention, the first step S1 is to blank the blank; the second step S2 is to pretreat the blank, and the pretreatment includes annealing, shot blasting and surface lubrication Processing; the third step S3, put the blank into figure 2 Mold clamping in the mold, cold extrusion, overflow one-step forming, to produce an oil pump cover plate forging 40 with two circles of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com