Full-automatic horizontal type wood splitting machine

A wood splitting machine, fully automatic technology, applied in the direction of wood splitting devices, wood processing appliances, manufacturing tools, etc., can solve the problems of low degree of mechanization, time-consuming and laborious manual operation process, inability to meet production and living requirements, etc., to reduce labor intensity, The effect of increasing labor productivity and reducing human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

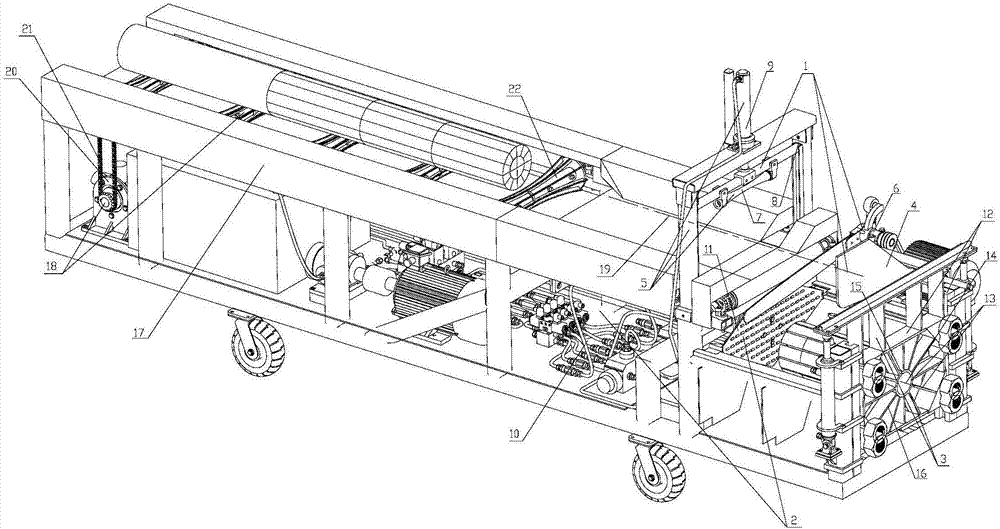

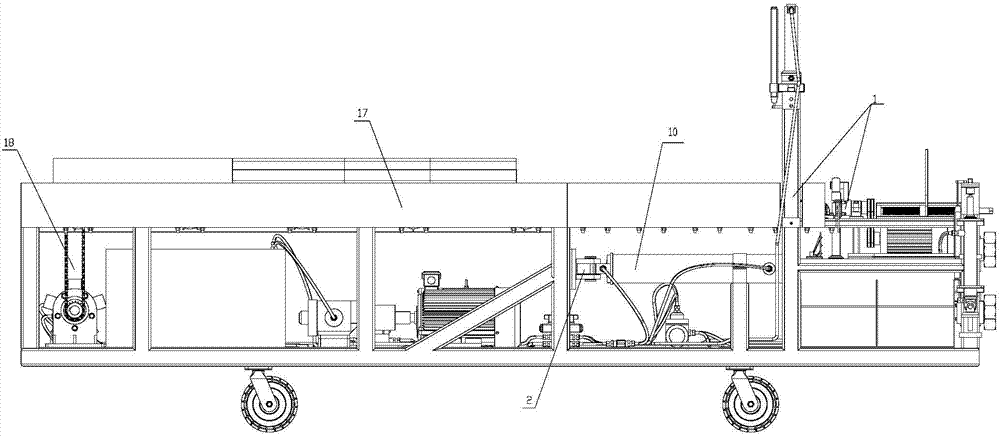

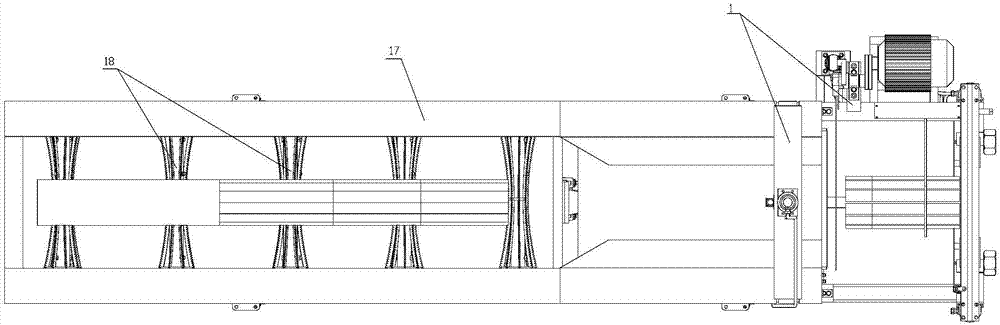

[0022] Such as figure 1 , figure 2 , image 3 as well as Figure 4 Shown is a fully automatic horizontal wood splitter provided by the present invention, which can effectively reduce the artificial reference degree of the operator, and further improve the automaticity of the wood splitting work. The full-automatic horizontal wood splitter includes an integer cutting mechanism 1, a chopping drive mechanism 2 and a chopping tool 3; during the chopping process of firewood, the trimming and chopping required by the trimming and cutting mechanism 1 Firewood, under the promotion of the chopping drive mechanism 2, is cut into small pieces of wood of specified size by the chopping tool 3. The present application sets up a set of fully automatic horizontal wood splitters including an integer cutting mechanism 1, a chopping drive mechanism 2 and a chopping tool 3, and in the process of chopping firewood, first passes through the integral cutting mechanism 1 The irregular firewood r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com