Low-shrinkage, low-warpage and soft-tactility polypropylene composite material used for automotive interior decoration and preparation method of polypropylene composite material

A composite material and automotive interior technology, applied in the field of soft-touch polypropylene composite materials and their preparation, can solve problems such as floating fiber and glass fiber product warpage, achieve soft touch, reduce shrinkage and warpage, prevent warping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

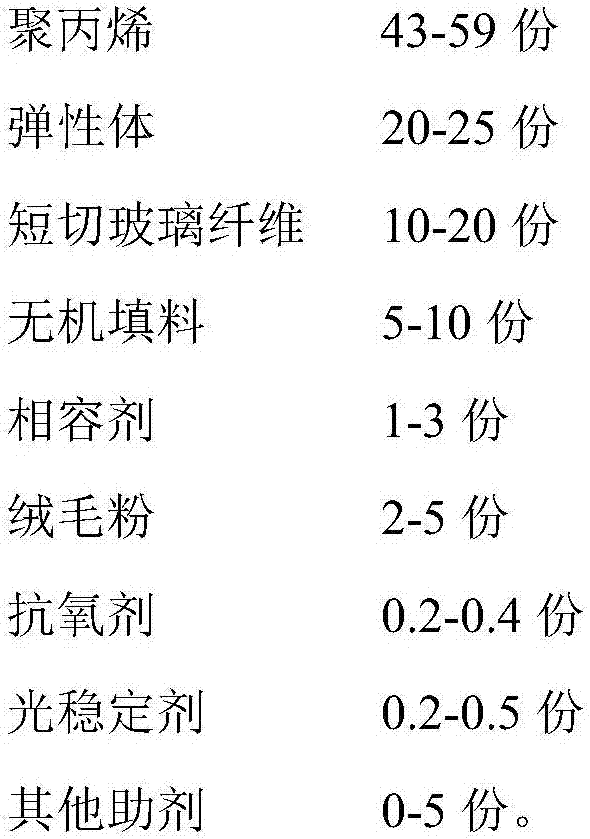

Method used

Image

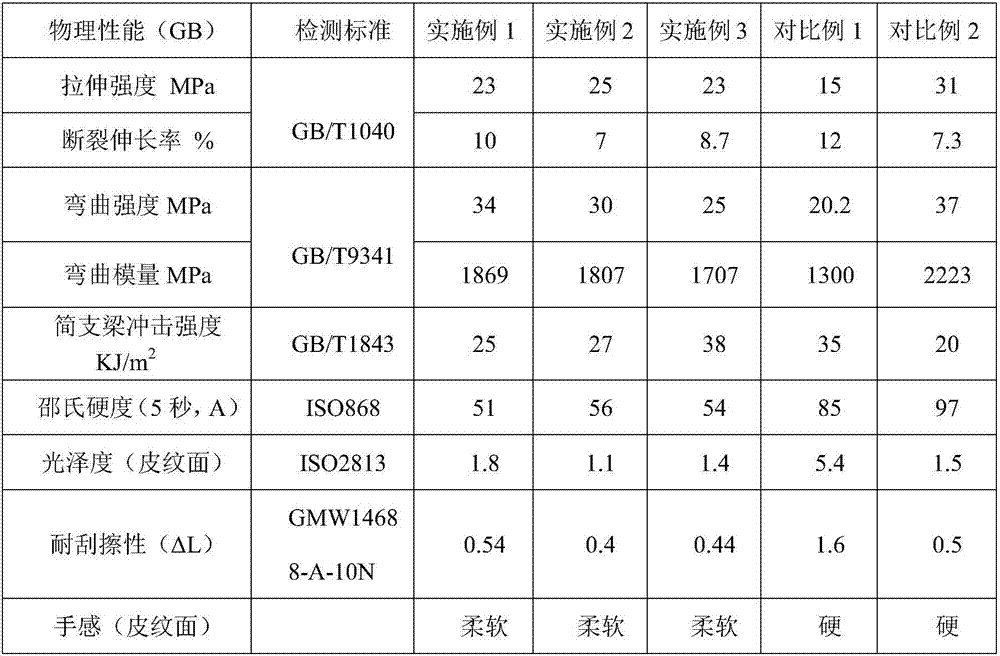

Examples

Embodiment 1

[0030] 59 parts of block copolymerized polypropylene, 20 parts of elastomer SBS, 10 parts of 2500 mesh calcium silicate, 1 part of polypropylene grafted maleic anhydride, 2 parts of fluff powder, 0.15 parts of antioxidant 1010, 0.15 parts of antioxidant 168 , 0.2 parts of hindered amine light stabilizer, 2 parts of anti-scratch agent are put into the high-speed mixer and blended for 5-10 minutes; 10 parts of glass fiber are added to the co-rotating twin-screw extruder together with step (1) Medium-melt blending extrusion granulation, the extrusion temperature is 190-220°C, and the vacuum degree is -0.04~-0.08.

Embodiment 2

[0032] Block copolymer polypropylene 52 parts, elastomer SBS 20 parts, 2100 mesh calcium silicate 5 parts, polypropylene grafted maleic anhydride 3 parts, fluff powder 5 parts, antioxidant 1010 0.1 part, antioxidant 168 0.1 part , 0.3 parts of hindered amine light stabilizer, 2 parts of anti-scratch agent are mixed in a high-speed mixer for 5-10 minutes; 20 glass fibers are added to the co-rotating twin-screw extrusion with the measured feeding material and step (1) Melt blending extrusion granulation, the extrusion temperature is 190-220°C, and the vacuum degree is -0.04~-0.08.

Embodiment 3

[0034] 43 parts of block copolymerized polypropylene, 20 parts of elastomer SEBS, 5 parts of ethylene-butene block copolymer, 10 parts of 3000 mesh calcium silicate, 2 parts of polypropylene grafted maleic anhydride, 5 parts of fluff powder, antioxidant 0.1 part of agent 1010, 0.1 part of antioxidant 168, 0.5 part of hindered amine light stabilizer, 2 parts of anti-scratch agent, and 1 part of lubricant TAF were mixed in a high-speed mixer for 5-10 minutes; 15 glass fibers were used The feeding material is added to the co-rotating twin-screw extrusion together with the step (1) to melt, blend, extrude and granulate. The extrusion temperature is 190-220° C., and the vacuum degree is -0.04~-0.08.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap