Composite drill applicable to middle Yangtze Cambrian system shale gas exploitation

A shale gas mining and Cambrian technology, applied in the field of field drilling tools, can solve the problem that PDC bits cannot replace roller cone bits, and achieve the effects of improving drilling efficiency, expanding the scope of application, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

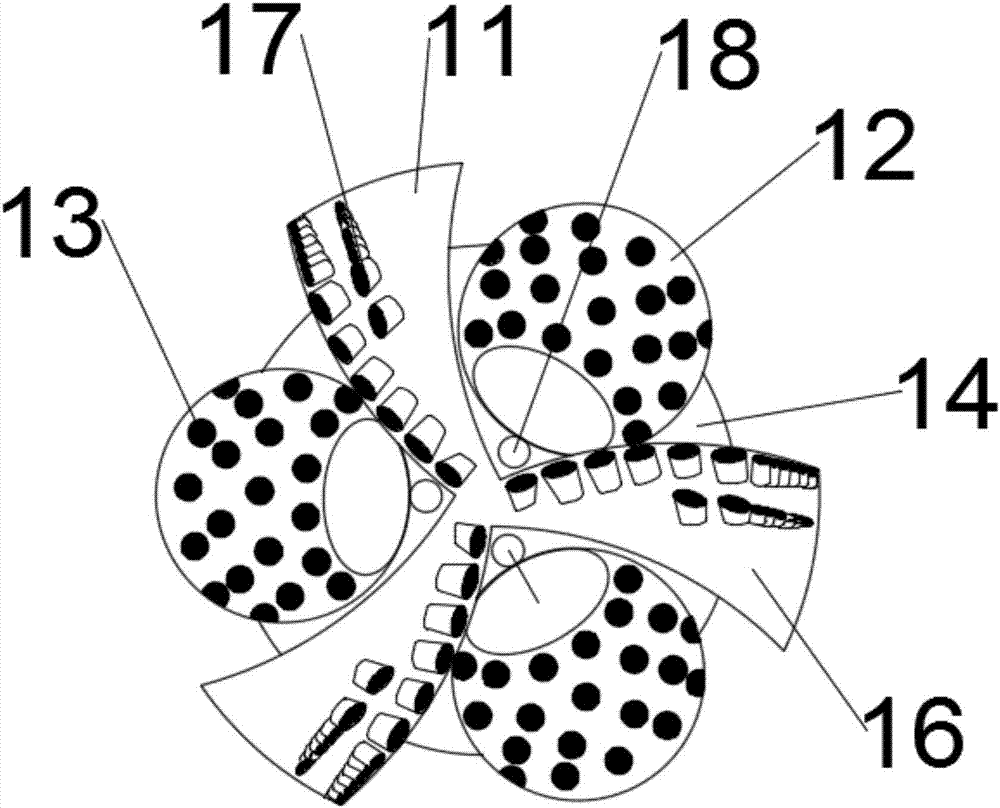

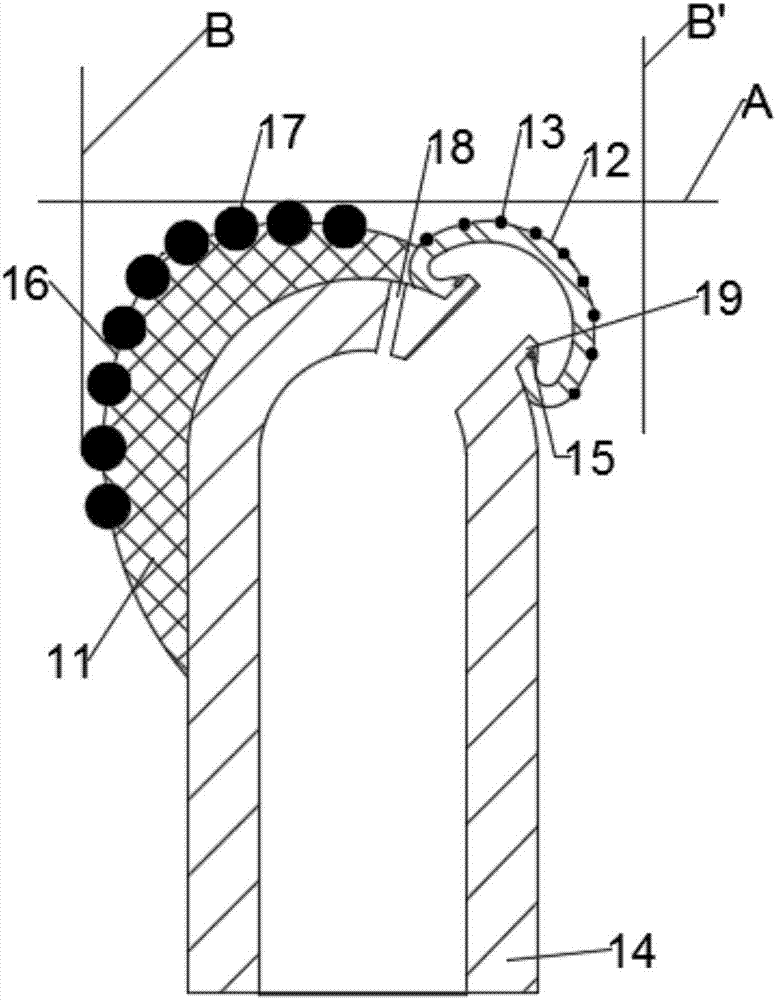

[0020] Such as figure 1 , figure 2 As shown, a compound drill bit suitable for Cambrian shale gas exploitation in the Middle Yangtze includes a drill body 14, which has a flushing cavity inside, and a cutting portion at the front end of the body, and the top of the cutting portion protrudes outward to form an arc shape. On the top surface, the protruding part of the cutting part is provided with three uniformly distributed main cutting edges 11, the main cutting edges 11 extend to the arc-shaped top surface and meet at the arc-shaped top surface, the main cutting edges 11 are formed along the drill body 14 is composed of a radial cutting surface and a back blade surface 16 extending in an arc to the surface of the body. The back blade surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com