Cooling device utilizing micronized boiling efficient heat exchange technology

A cooling device and miniaturization technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of hindering the miniaturization of bubbles and boiling, wall burning, etc., and achieve extremely high working heat load Cooling problems of devices and equipment, convenient processing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing example the present invention is described in more detail: the present embodiment is implemented under the premise of the technical solution of the present invention, has provided detailed implementation scheme and specific operation process, but the protection scope of the present invention is not limited to the following examples.

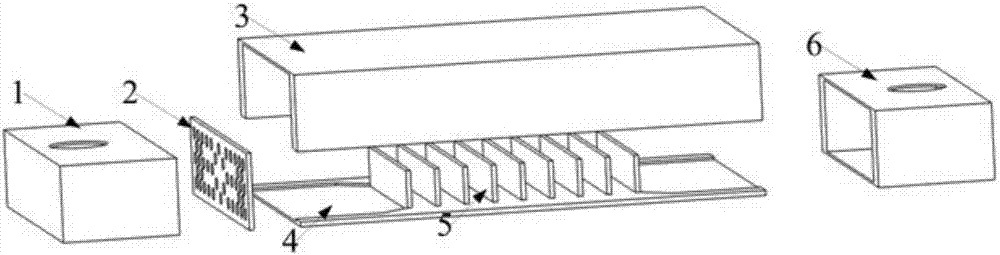

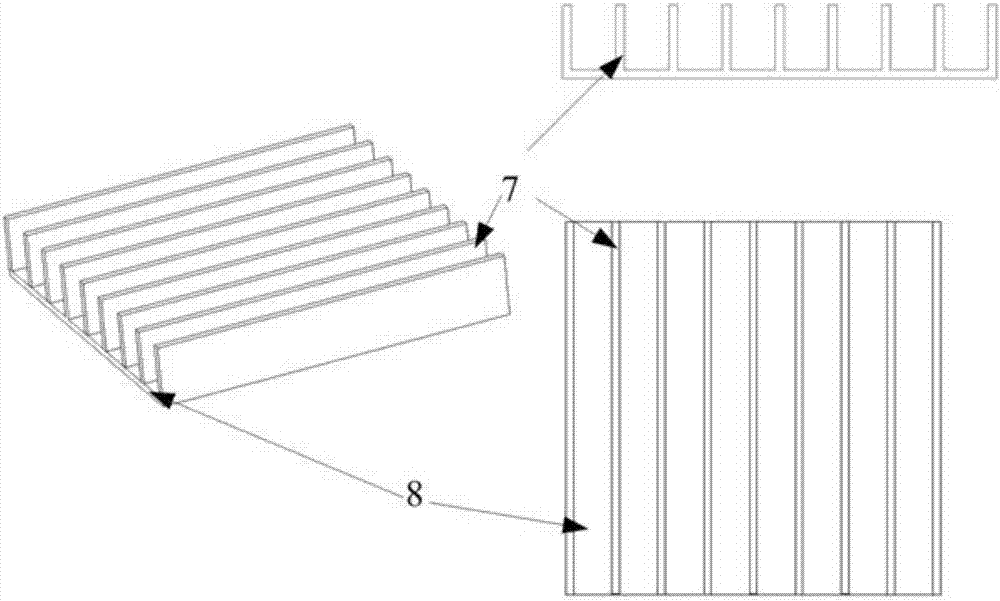

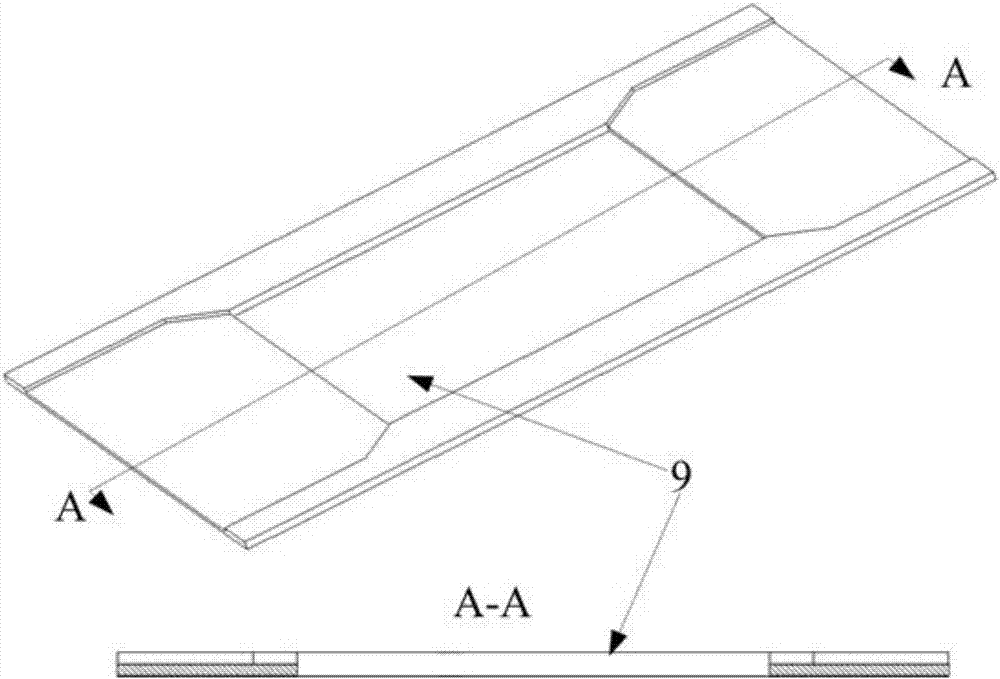

[0022] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention mainly includes a water inlet chamber 1, an equalizing orifice plate 2, a flow distribution structure 3, a bottom plate 4, a ribbed heat exchange plate 5 and a water outlet chamber 6. The coolant is degassed water as an example. The subcooling degree of the coolant at the inlet of the water inlet chamber 1 is recommended to be in the range of 40-70K, the size of the ribbed heat exchange plate 5 is 20 cm×20 cm, and the heating power at the bottom is 100 kW.

[0023] see figure 2 , heat is introduced into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com