Production and processing technology of moxa floss

A processing technology and moxa velvet technology, applied in the field of moxa velvet production and processing technology, can solve the problem that moxa velvet fibers are not conducive to moxa velvet production, and achieve the effects of saving time and effort in the production process, easier separation, and fast production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment discloses a production and processing technology of moxa, including the following steps:

[0028] (1) Select the materials, choose the three-year-old wormwood leaves that are sealed and kept away from light, pick out the branches and impurities in the wormwood leaves, and remove the moldy wormwood leaves;

[0029] (2) Mugwort leaf treatment, steam the selected mugwort leaves with boiling water for 1 minute, and then use a dryer to dry the mugwort leaves at a drying temperature of 70°C and bake for 20 minutes;

[0030] (3) Crushing, use a crusher to break up the selected mugwort leaves, and crush the mugwort leaves;

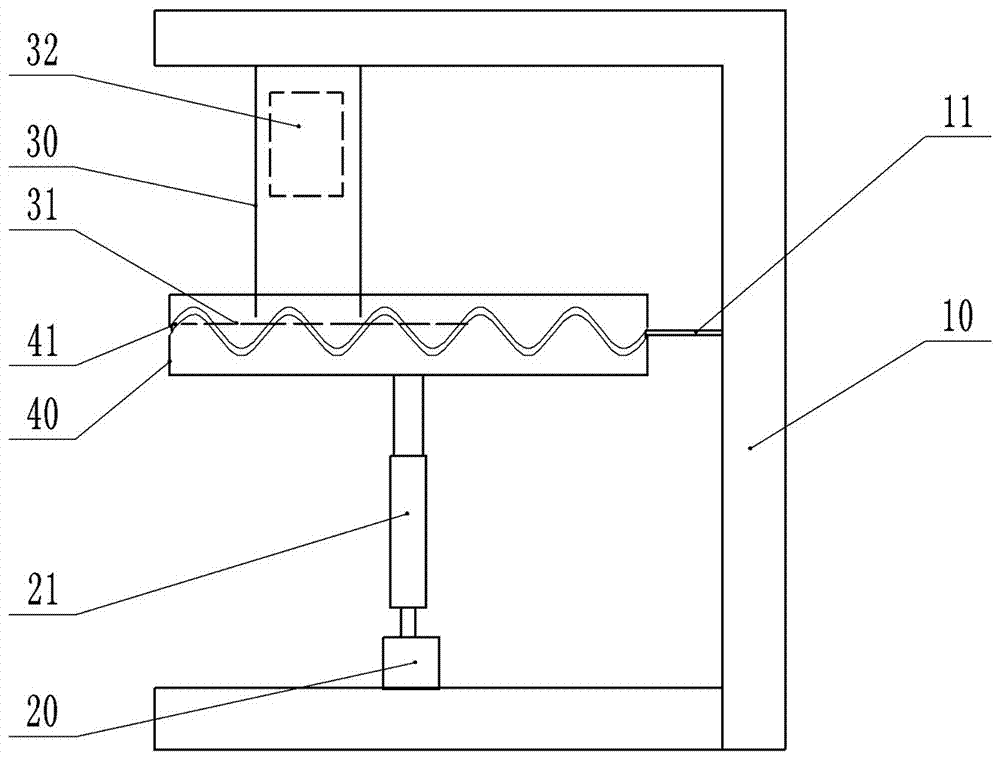

[0031] (4) Screening, using a screening device to select and remove the branches and impurities of the broken mugwort leaves; figure 1 The screening device shown includes a stirring rod 30, a telescopic rod 21, a support 10 and a rotating screen 40. A motor 20 is fixed on the support 10. The output shaft of the motor 20 passes through the telescopic...

Embodiment 2

[0040] The difference between Embodiment 2 and Embodiment 1 is:

[0041] In step (1), choose 4 years old wormwood that is sealed and protected from light;

[0042] In step (2), use boiling water steam to steam the selected mugwort leaves for 1.5 minutes, and then use a dryer to dry the mugwort leaves at a drying temperature of 75°C and bake for 25 minutes;

[0043] In step (5), the diameter of the screen hole in the hammer mill is 1.2 mm;

[0044] Repeat step (5) and step (6) 20 times in step (7).

[0045] Through experimental testing, the moxa prepared by the processing technology of this embodiment has a ratio coefficient higher than 25:1, better color, and very high output of moxa.

Embodiment 3

[0047] The difference between Embodiment 3 and Embodiment 1 is:

[0048] In step (2), use boiling water steam to steam the selected mugwort leaves for 2 minutes, and then use a dryer to dry the mugwort leaves at a drying temperature of 80°C and bake for 30 minutes.

[0049] Through experimental testing, the moxa prepared by the processing technology of this embodiment has a ratio coefficient higher than 25:1, better color, and higher yield of moxa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com