A mining method for low-grade solid potassium ore

A technology of solid potassium ore and mining method, which is applied in ground mining, earth square drilling, underground mining, etc. It can solve problems such as difficult to guarantee brine sources, difficult to use directly, and variable components, so as to achieve the best brine water quality and protection The effect of reducing the skeleton of the ore deposit and the amount of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

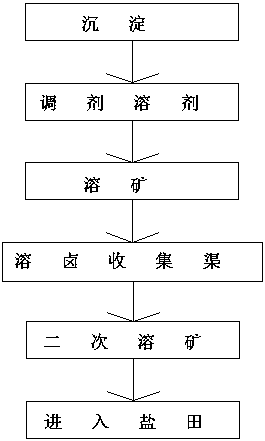

[0025] Embodiment 1, a kind of mining method of low-grade solid potash ore is characterized in that: it is finished by the following steps:

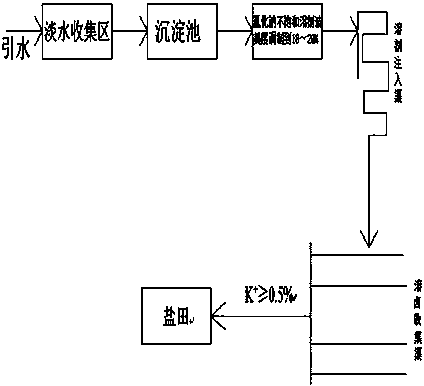

[0026] The first step, sedimentation: the fresh water is deposited in the sedimentation tank before the fresh water is introduced into the mining area. The sedimentation time is 2.5 days.

[0027] The second step is to prepare the solvent: introduce the fresh water precipitated in the first step into the solvent adjustment area of the mining area, and adjust the Baume degree of the sodium chloride unsaturated solvent to 18%-20% at an average outdoor temperature of 15°C;

[0028] The third step, ore dissolution: introduce the brine with sodium chloride in the second step into the solution mining channel, and the construction of the solution mining channel is in the proposed driving solution mining unit, and the solution mining channel is formed by excavating multiple excavations in parallel on the plane The channels distributed in a clo...

Embodiment 2

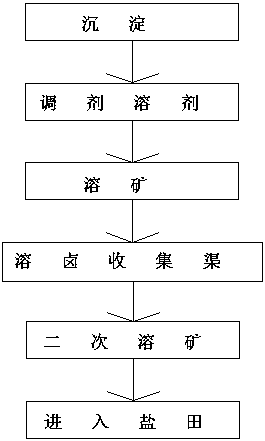

[0035] Embodiment 2, a kind of mining method of low-grade solid potash ore is characterized in that: it is completed by the following steps:

[0036] The first step, sedimentation: the fresh water is deposited in the sedimentation tank before the fresh water is introduced into the mining area. The sedimentation time is 3 days.

[0037] The second step is to prepare the solvent: introduce the fresh water precipitated in the first step into the solvent adjustment area of the mining area, and adjust the Baume degree of the sodium chloride unsaturated solvent to 18%-20% at an average outdoor temperature of 25°C;

[0038] The third step, ore dissolution: introduce the brine with sodium chloride in the second step into the solution mining channel, and the construction of the solution mining channel is in the proposed driving solution mining unit, and the solution mining channel is formed by excavating multiple excavations in parallel on the plane The channels distributed in a clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com