Environment-friendly firing device for rear earth

An environmentally friendly, rare earth technology, applied in waste heat treatment, furnaces, lighting and heating equipment, etc., can solve problems such as unfavorable enterprise production and development, people's health injury, no environmental protection devices, etc., to improve work speed and facilitate adjustment. , the effect of convenient speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

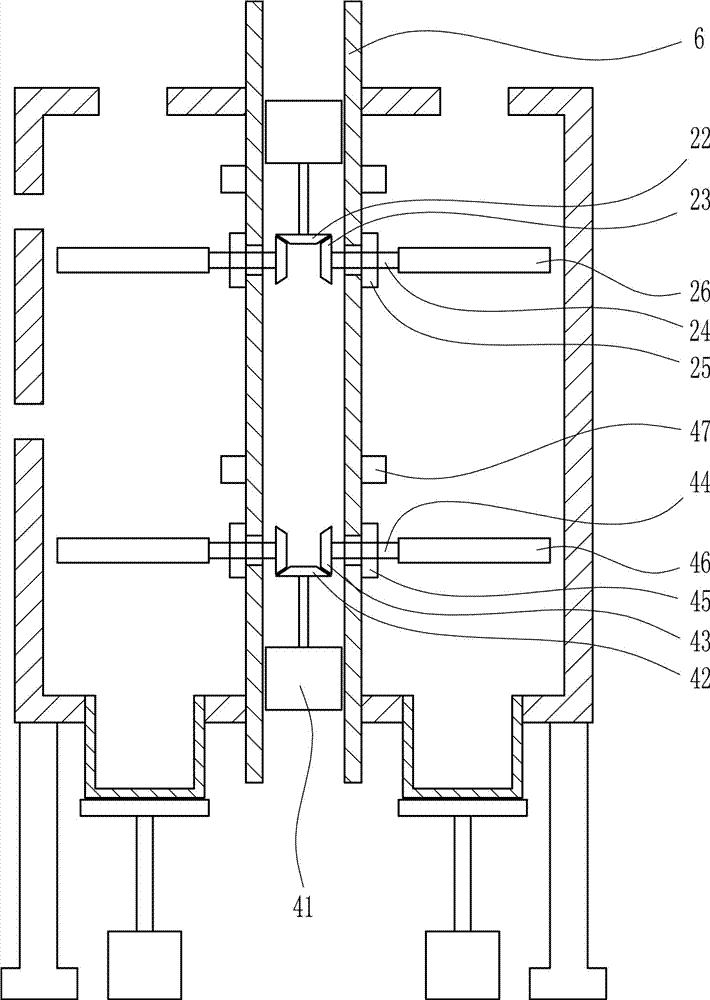

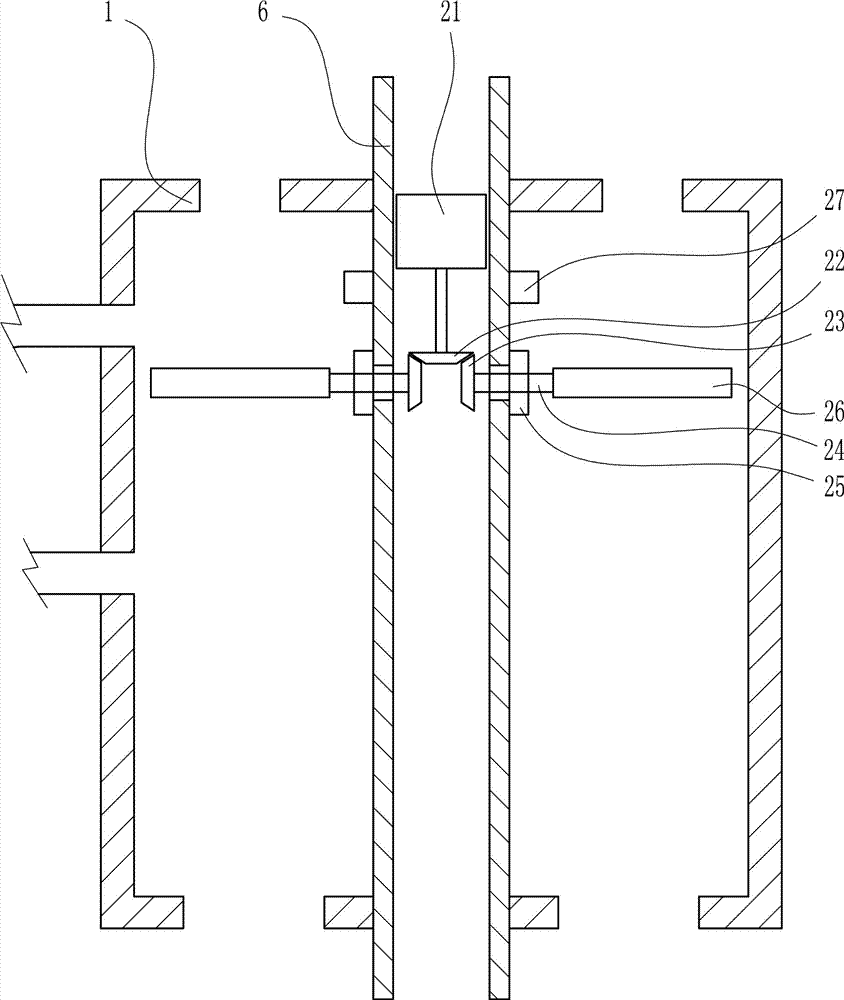

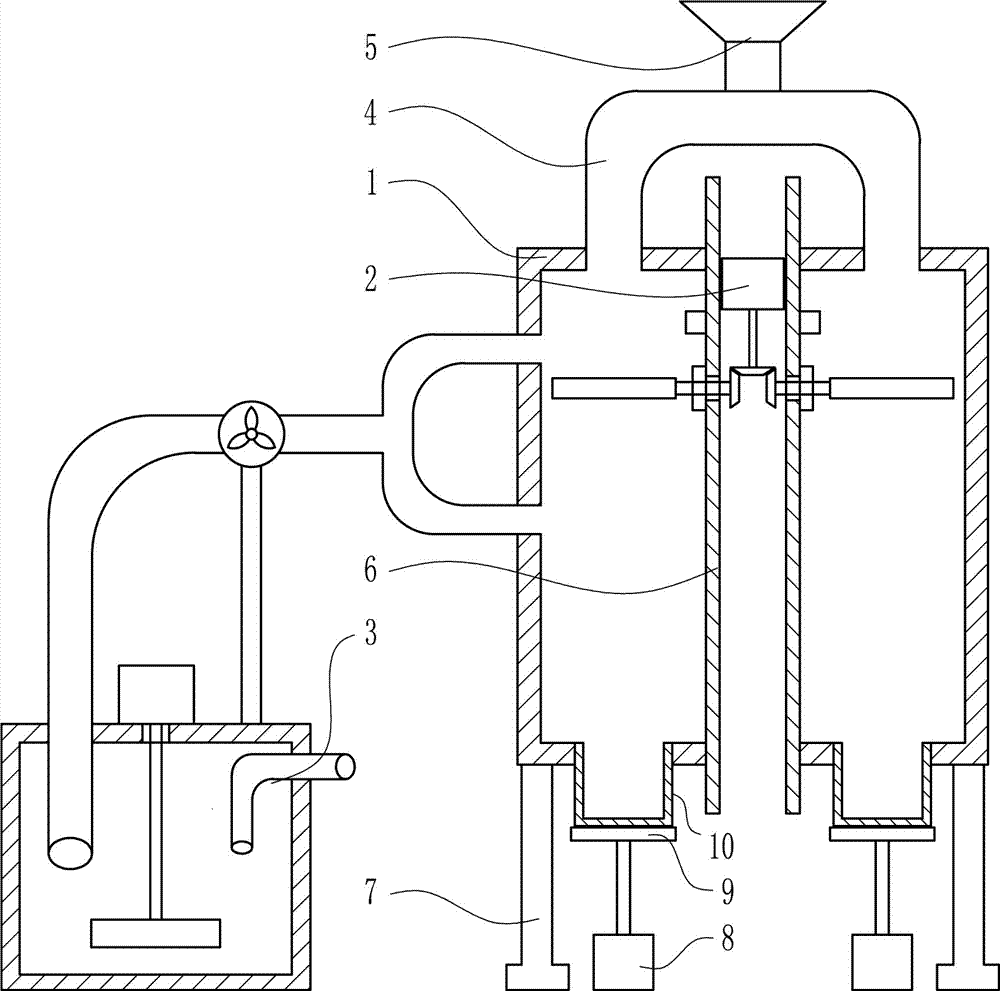

[0029] An environment-friendly burning device for rare earth, such as Figure 1-5 As shown, it includes a furnace body 1, a burning turning device 2, a filtering device 3, a U-shaped bin 4, a hopper 5, a rectangular tube 6, legs 7, an upper and lower cylinder 8, a tray 9 and a receiving cylinder 10; A burning turning device 2 is arranged on the furnace body 1, and a filter device 3 is arranged on the left side of the furnace body 1. The top of the body 1 is connected to the U-shaped feed bin 4 by welding, the outlet of the U-shaped feed bin 4 corresponds to the feed inlet on the top of the furnace body 1, and the top of the U-shaped feed bin 4 is connected to the feeding hopper. 5. It is connected by welding. There are symmetrical openings in the middle of the top and bottom of the furnace body 1. The rectangular tube 6 extends downwards into the furnace body 1 through the opening on the top of the furnace body 1 and passes through the opening at the bottom of the furnace body...

Embodiment 2

[0031] An environment-friendly burning device for rare earth, such as Figure 1-5 As shown, it includes a furnace body 1, a burning turning device 2, a filtering device 3, a U-shaped bin 4, a hopper 5, a rectangular tube 6, legs 7, an upper and lower cylinder 8, a tray 9 and a receiving cylinder 10; A burning turning device 2 is arranged on the furnace body 1, and a filter device 3 is arranged on the left side of the furnace body 1. The top of the body 1 is connected to the U-shaped feed bin 4 by welding, the outlet of the U-shaped feed bin 4 corresponds to the feed inlet on the top of the furnace body 1, and the top of the U-shaped feed bin 4 is connected to the feeding hopper. 5. It is connected by welding. There are symmetrical openings in the middle of the top and bottom of the furnace body 1. The rectangular tube 6 extends downwards into the furnace body 1 through the opening on the top of the furnace body 1 and passes through the opening at the bottom of the furnace body...

Embodiment 3

[0034] An environment-friendly burning device for rare earth, such as Figure 1-5 As shown, it includes a furnace body 1, a burning turning device 2, a filtering device 3, a U-shaped bin 4, a hopper 5, a rectangular tube 6, legs 7, an upper and lower cylinder 8, a tray 9 and a receiving cylinder 10; A burning turning device 2 is arranged on the furnace body 1, and a filter device 3 is arranged on the left side of the furnace body 1. The top of the body 1 is connected to the U-shaped feed bin 4 by welding, the outlet of the U-shaped feed bin 4 corresponds to the feed inlet on the top of the furnace body 1, and the top of the U-shaped feed bin 4 is connected to the feeding hopper. 5. It is connected by welding. There are symmetrical openings in the middle of the top and bottom of the furnace body 1. The rectangular tube 6 extends downwards into the furnace body 1 through the opening on the top of the furnace body 1 and passes through the opening at the bottom of the furnace body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com