Thin slab continuous casting and rolling roll gap value dynamic self-adaptive control method

A dynamic self-adaptive, thin slab continuous casting technology, applied in the direction of self-adaptive control, general control system, control/adjustment system, etc., can solve problems such as low timeliness, low model accuracy, and inability to guarantee simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0088] The present invention provides a dynamic self-adaptive control method for the roll gap value aiming at the present situation that the adjustment precision of the roll gap value in the existing continuous casting technology is not enough, and the external interference is large, and the continuous casting production requirement cannot be met.

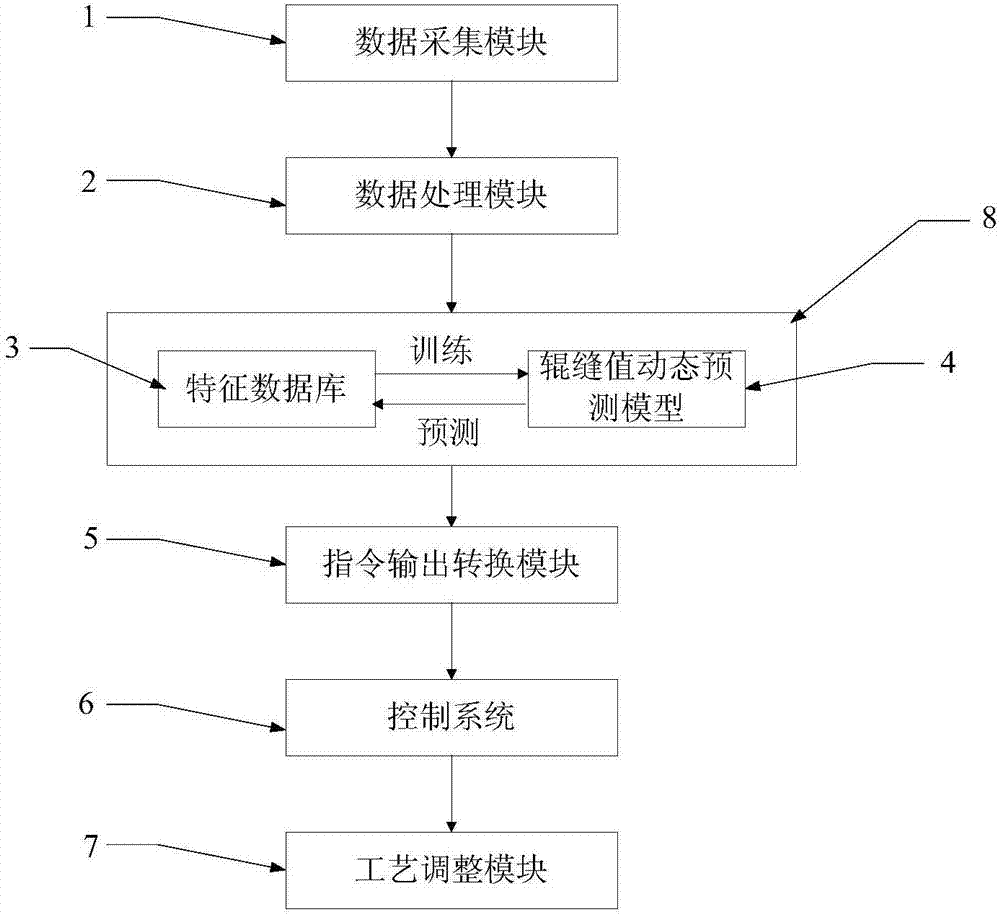

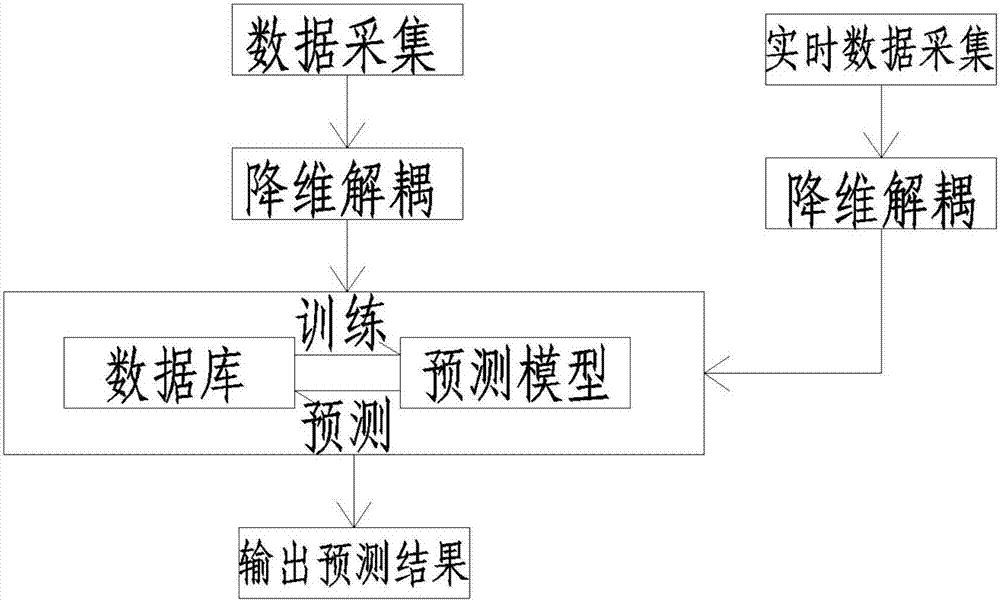

[0089] see figure 1 and figure 2 , The system structure of the present invention includes: a data acquisition module 1, a data processing module 2, an instruction output conversion module 5, a control system 6, a process adjustment module 7 and a black box model 8. The black box model 8 is composed of a feature database 3 and a dynamic prediction model 4 of the roll gap value.

[0090] (1) The data acquisition module 1 is based on the data acquisition of the existing continuous casting production line, includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com