Control system and method for driving threshing cylinder of combine harvester

A technology for combine harvesters and threshing drums, applied to harvesters, threshing equipment, cutters, etc., can solve problems such as lagging and difficulty in parameter detection, achieve the effect of ensuring harvesting effect and simplifying the mechanical transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

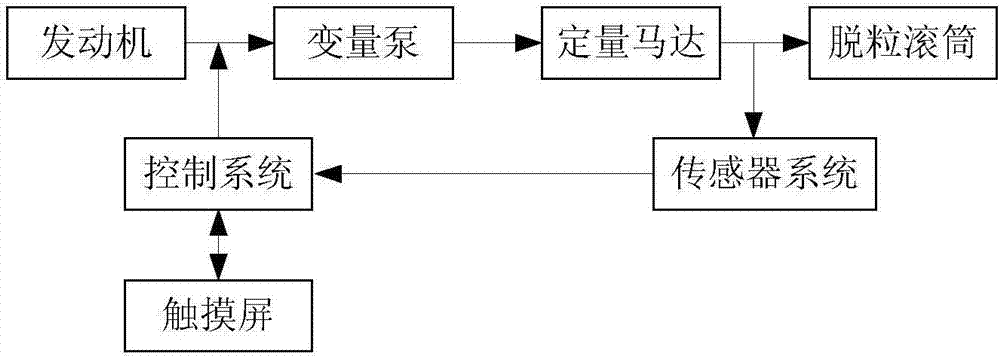

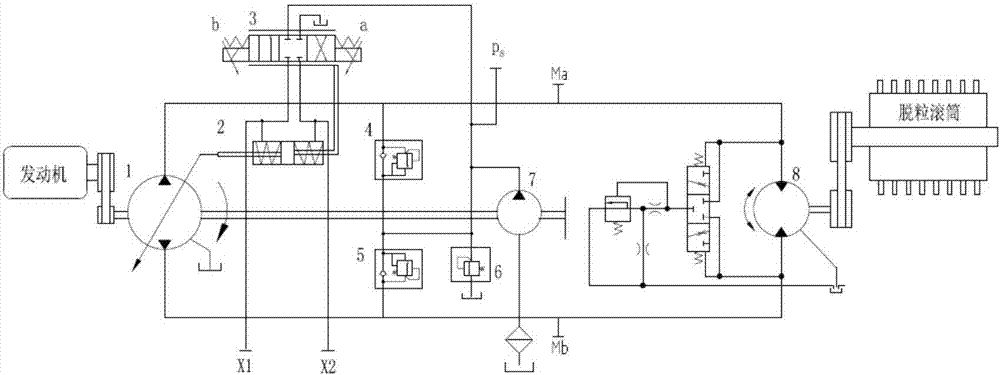

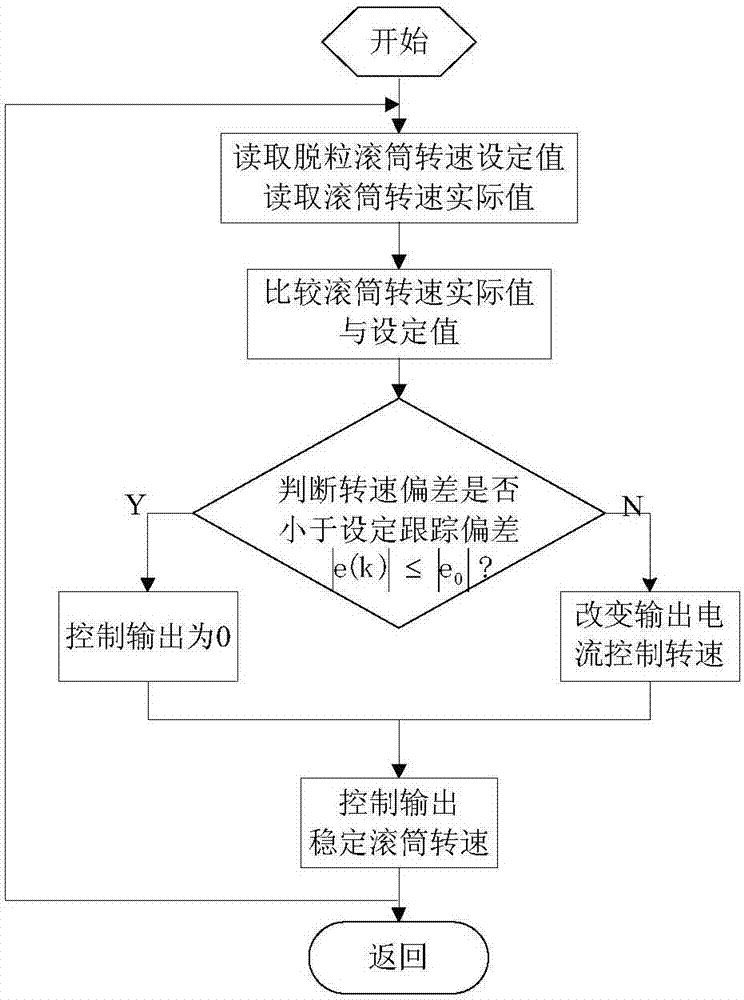

[0035] The composition and basic working principle of the combine harvester threshing drum drive control system in this embodiment can be used figure 1 Simply put, it is actually composed of hydraulic and electric control. Among them, the pump-controlled motor system consists of an electro-hydraulic proportional variable pump and a hydraulic motor to form a closed main circuit. The inclination of the swash plate of the pump is adjusted through the variable mechanism, so that the displacement of the pump corresponds to the input signal, and the output speed of the motor is controlled. The electronic control part includes speed sensor, pressure sensor, PLC, proportional amplifier, touch screen, etc. On the touch screen, you can select the type of crop to be harvested or set the working speed of the threshing drum. The speed and system pressure are detected by the speed sensor and pressure sensor. The PLC collects the sensor signal and processes it to output the control current....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com