Double-table-top laser cutting machine and cutting method thereof

A laser cutting machine, double table technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of inconvenient automatic on-line processing, to improve laser processing efficiency, shorten time, improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

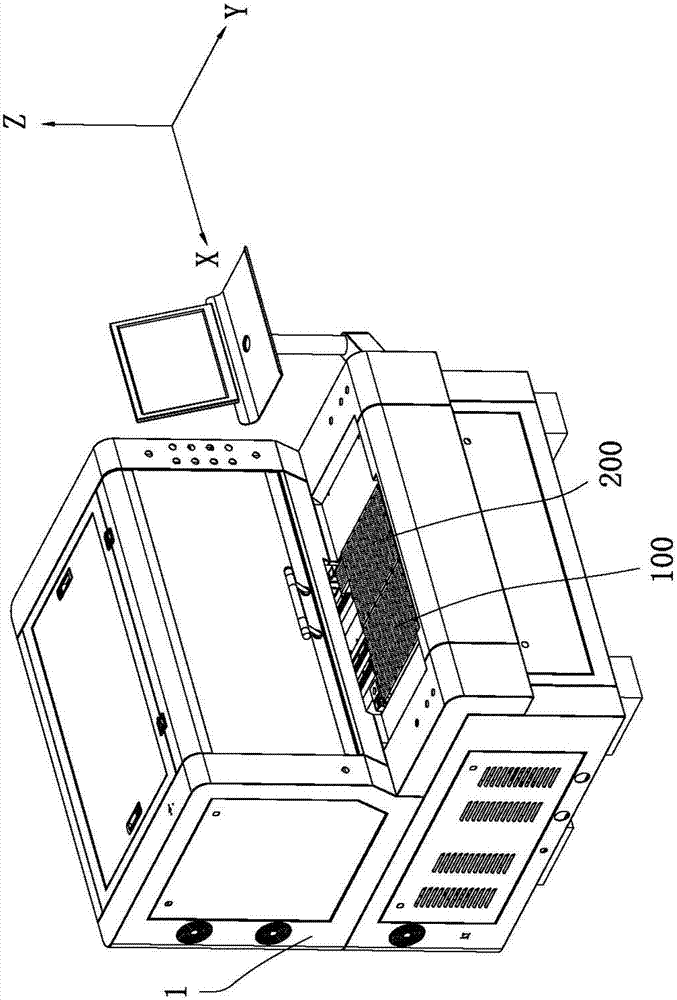

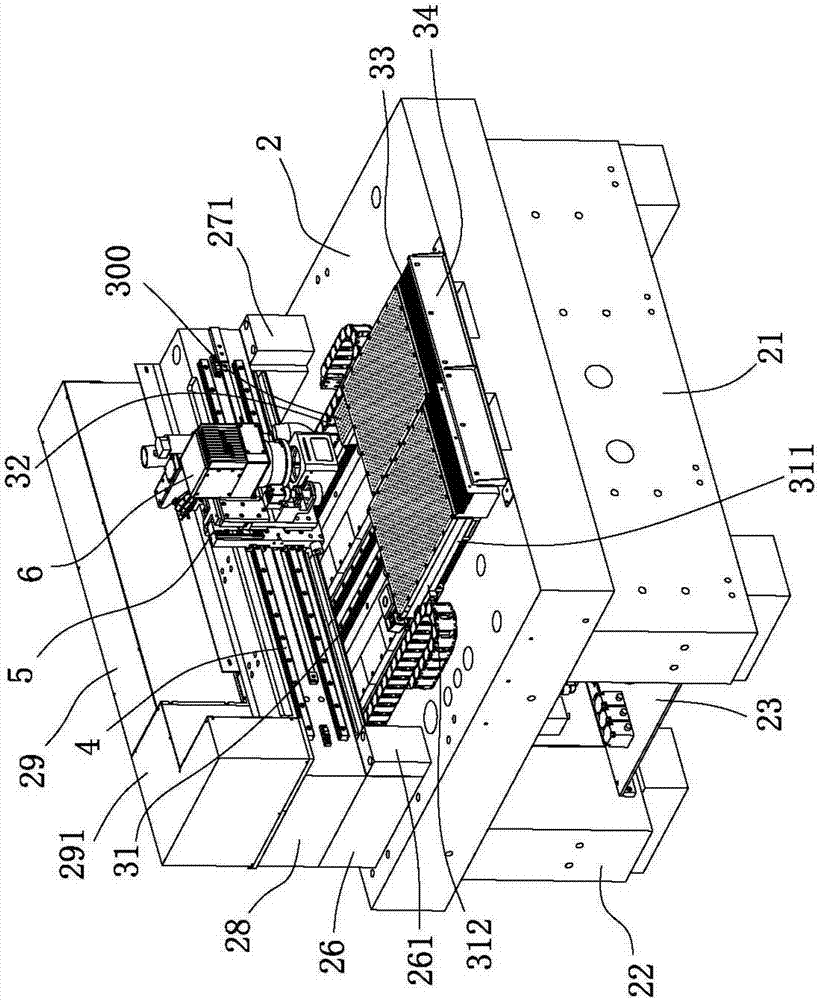

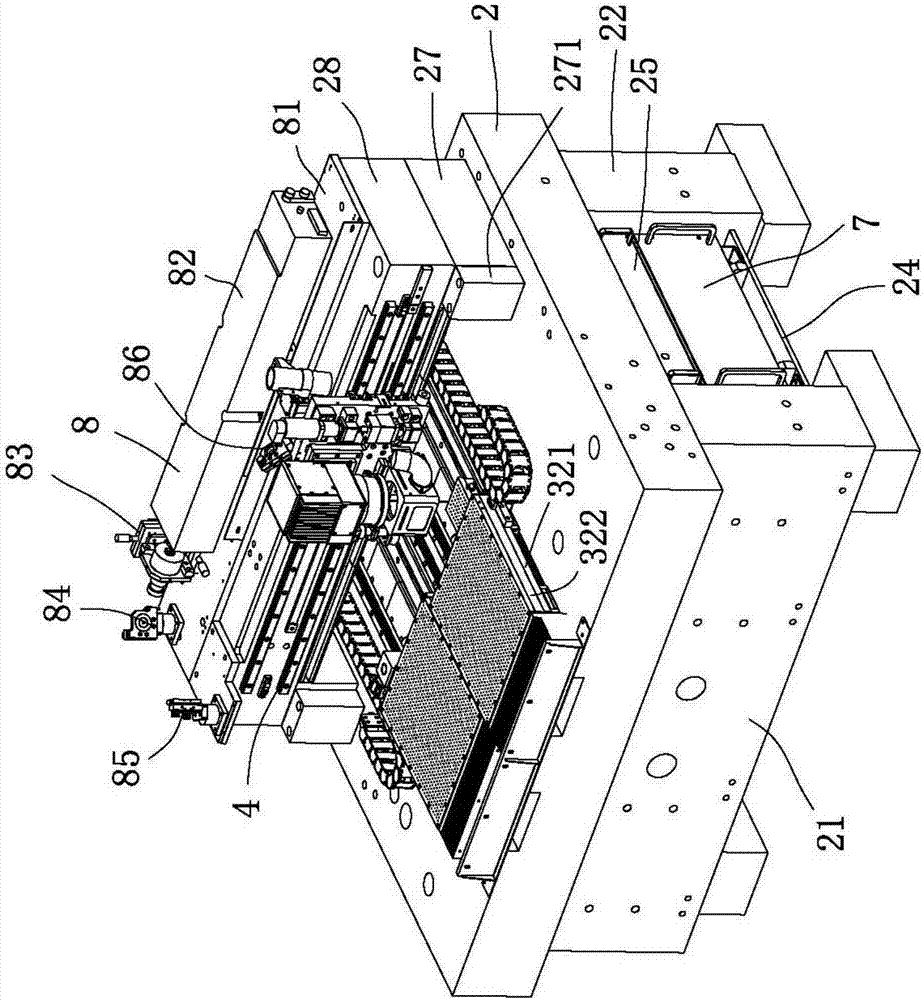

[0027] Such as figure 1 and figure 2 As shown, the double-table laser cutting machine of the present invention is provided with a parallel left worktable 100 and a right worktable 200, which includes: a housing 1, a marble bed 2, a left first-direction linear motion mechanism 31, a right first-direction linear motion Mechanism 32 , second-direction linear motion mechanism 4 , third-direction linear motion mechanism 5 , vision control system 6 , industrial computer 7 , and laser control system and optical-mechanical system 8 . Wherein, the left first direction linear motion mechanism 31 and the right first direction linear motion mechanism 32 are all fixed on the surface of the bed 2; the second direction linear motion mechanism 4 is fixed on the side of the beam 29, and the laser control The system and the optical mechanical system 8 fix the surface of the beam 29 ; the vision control system 6 is fixed on the third-direction linear motion mechanism 5 and is located above one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com