Acidic waste water treatment device and using method thereof

A technology of acid waste water and treatment device, applied in water treatment, environmental protection, chemical industry, can solve the problem of acid waste water being difficult to treat, and achieve the effect of reducing the total amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、70

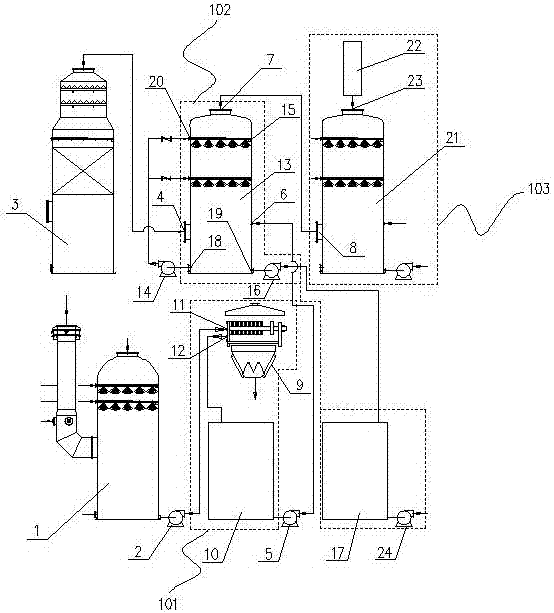

[0034] Embodiment 1, 700,000 tons of sulfuric acid system:

[0035] Use the acid water supplement pump 5 to send the acidic waste water into the evaporation tower 13. After reaching a certain liquid level, turn on the evaporation tower circulation pump 14, and the dry flue gas passing into the absorption tower 3 has a water content of ≤0.1g / m 3 , the flue gas volume at gas inlet 4 of the evaporation tower is 226976Nm 3 / h-258278Nm 3 / h, temperature: 61-69°C, the flue gas is in countercurrent contact with the top-to-bottom spray acid water of the spray device 15, and part of the moisture in the acid water is taken away, and the moisture content of the flue gas reaches 3-4g / m 3 Then enter the tail suction tower 21, after the gas is treated up to the standard through the tail suction tower 21, it enters the exhaust chimney 22 from the tail suction tower gas outlet 23 and discharges up to the standard.

[0036] In this embodiment, the evaporation tower supplements 700m of acid w...

Embodiment 2、48

[0037] Embodiment 2, 480,000 tons of sulfuric acid system:

[0038] Use the acid water supplement pump 5 to send the acidic waste water into the evaporation tower 13. After reaching a certain liquid level, turn on the evaporation tower circulation pump 14, and the dry flue gas passing into the absorption tower 3 has a water content of ≤0.1g / m 3 , the flue gas volume at gas inlet 4 of the evaporation tower is 157982Nm 3 / h-178469Nm 3 / h, temperature: 71-77°C, the flue gas is in countercurrent contact with the top-to-bottom spray acid water of the spray device 15, and part of the moisture in the acid water is taken away, and the moisture content of the flue gas reaches 6-7g / m 3 Then enter the tail suction tower 21, after the gas is treated up to the standard through the tail suction tower 21, it enters the exhaust chimney 22 from the tail suction tower gas outlet 23 and discharges up to the standard.

[0039] In this embodiment, the evaporation tower supplements acid water 245...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com