Bio-based composite material as well as preparation method and application thereof

A composite material and bio-based technology, applied in the field of bio-based composite materials and their preparation, can solve the problems of weak interface adsorption, unfavorable formation of composite materials, and huge differences in surface properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of described cyclodextrin / polyethylene glycol complex is as follows:

[0048] Dissolve a certain amount of cyclodextrin in water at 60°C to obtain a saturated aqueous solution of cyclodextrin, and add a certain amount to the saturated aqueous solution of cyclodextrin according to the molar ratio of cyclodextrin to polyethylene glycol Polyethylene glycol, and mechanically stirred for 1h, at room temperature, stood still for 24h, a precipitate appeared. The precipitate was vacuum-filtered, washed, and vacuum-dried at 30°C until constant weight. The molar ratio of cyclodextrin to polyethylene glycol is 1:1.

[0049] The applicant found that adding the cyclodextrin / polyethylene glycol compound can not only play a plasticizing role, but also increase its high temperature resistance, and it will not damage its structure even if it is soaked in hot water for a long time.

[0050] The antioxidant may include: at least one of phenolic antioxidants, phosp...

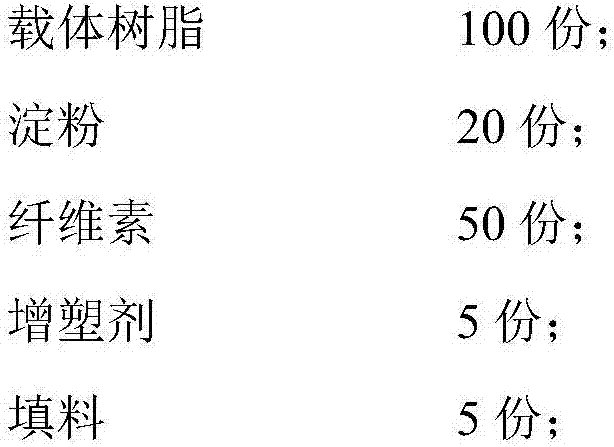

Embodiment 1

[0070] This embodiment 1 provides a bio-based composite material, at least including the following raw materials, in parts by weight,

[0071] 100 parts of carrier resin;

[0072] 1 part starch;

[0073] Cellulose 80 parts.

[0074] The carrier resin is polypropylene;

[0075] The starch is corn starch;

[0076] The cellulose is flax fiber;

[0077] The preparation method of the bio-based composite material at least includes the following steps:

[0078] The raw materials were mixed in a high-speed mixer, and stirred at 30° C. for 30 minutes.

Embodiment 2

[0080] This embodiment 2 provides a bio-based composite material, at least including the following raw materials, in parts by weight,

[0081] 100 parts of carrier resin;

[0082] 30 parts of starch;

[0083] Cellulose 1 part.

[0084] The carrier resin is polypropylene;

[0085] The starch is corn starch;

[0086] The cellulose is bagasse fiber;

[0087] The preparation method of the bio-based composite material at least includes the following steps:

[0088] The raw materials were mixed in a high-speed mixer, and stirred at 30° C. for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com