Construction method for constructing filling pile with electric drill and rotary digging relay drill

A technology of cast-in-situ piles and electric drills, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increasing the pulling load of rotary excavation pile bodies, unfavorable hole wall stability, and easy generation of negative pressure, etc., to reduce construction costs. Cost, good promotional value, effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

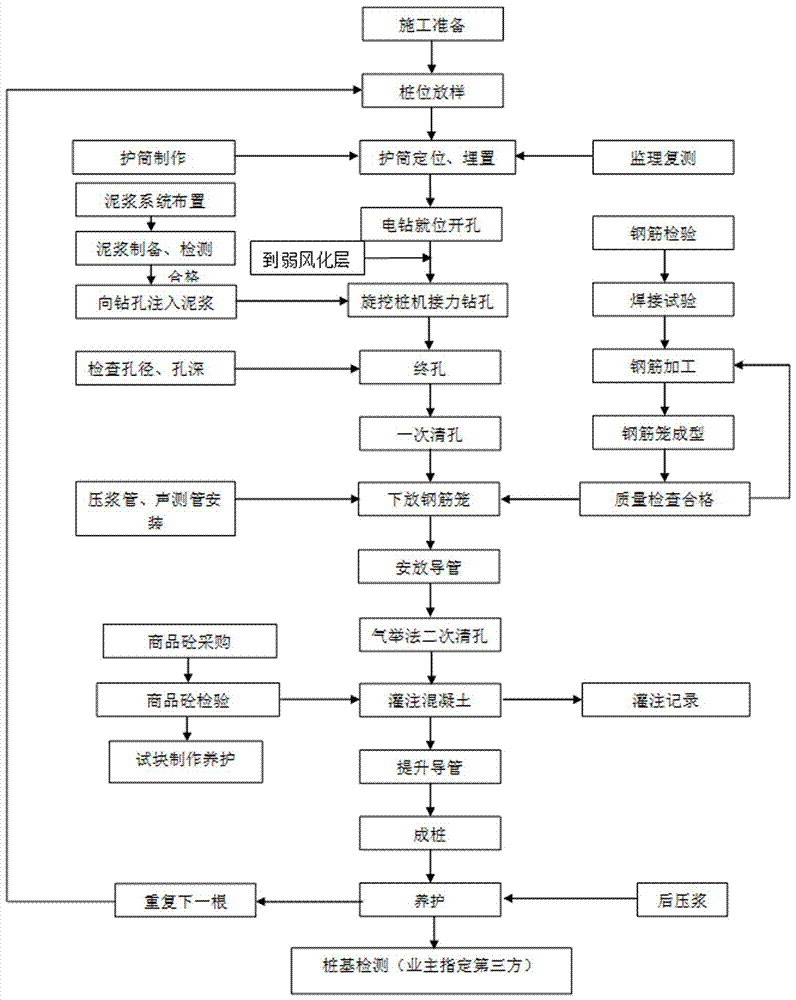

Method used

Image

Examples

Embodiment 1

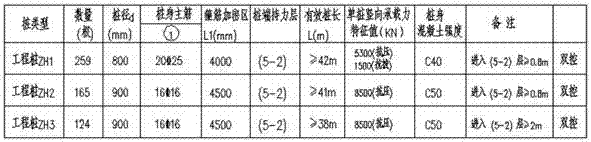

[0058] Project overview: The first phase of the Sanyang Road wind tower supporting project of an urban rail transit line 7 is located at the junction of Sanyang Road and Zhongshan Avenue. It consists of a tower and a skirt building, with 3 floors underground and 46 floors above the ground. The podium has 7 floors above ground, and the building height is 216m. The design grade of the pile foundation of this project is Grade A. The foundation adopts bored pile (post-grouting) foundation, the designed pile type is Φ800mm and Φ900mm, and the bearing layer at the pile tip is (5-2) layers of medium cemented conglomerate or medium cemented sandstone as the bearing layer at the pile tip. The depth is ≥2m (the depth of the engineering piles in the podium area is ≥0.8m).

[0059] The summary table of pile foundation design parameters is as follows:

[0060]

[0061] Geological conditions: from top to bottom soil layers are:

[0062] 1) 1-2 plain fill: the age of accumulation varie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com