Construction method for reverse direction underground excavation of large inclination-angle escalator passage in thin-layer crushed hard rock stratum

A technology of rock formation and construction method, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as difficulty in ensuring safety in use and operation, frequent excavation disturbances, narrow working space, etc., and achieve economic and social benefits Significant, less disturbance times, strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

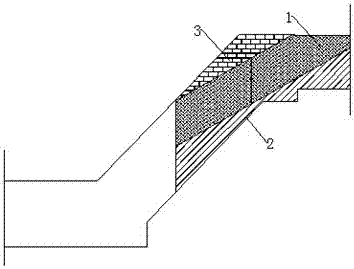

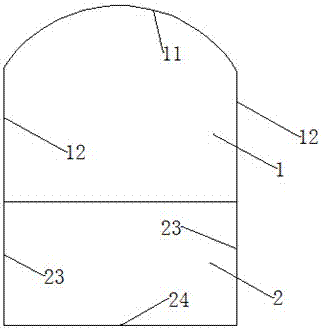

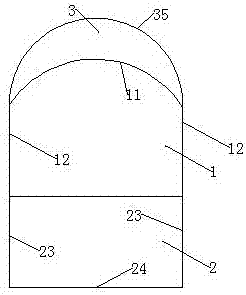

[0066] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1-Figure 3 As shown, the reverse direction underground excavation construction method of the escalator channel with a large dip angle in the thin-layer broken hard rock stratum includes the following construction steps:

[0067] Step S1: construction preparation;

[0068] Step S2: Construction of the lower pilot tunnel; the lower pilot tunnel includes an upper step and a lower step; the upper step includes I zone 1 and III zone 3, and the I zone 1 includes the first support area 11 and the second support District 12; the lower steps include II District 2, and the II District 2 includes the third support area 23 and the fourth support area 24; specifically include the following construction steps:

[0069] Step S21: advance support; to reduce vibration and dust, the excavation cycle footage is controlled at 0.8-1.0m;

[0070] Step S22: Excavation in Zone I 1 and support in the f...

Embodiment 2

[0087] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1-Figure 3 As shown, further, in order to better realize the present invention, the step S22 specifically includes the following steps:

[0088] Step S22: After the blasting operation is completed, the slag is removed, and the rock face is sealed with C25 concrete plain spray;

[0089] Step S222: Erection of a steel frame, supporting with anchors, nets, and spray systems;

[0090] It should be noted that, through the above improvements, after the blasting operation is completed, the slag is removed, and the rock surface is sealed with C25 concrete plain spray; steel frames are erected, and anchors, nets, and spray systems are supported; The initial support steel frame is equipped with 4 locking foot grouting anchor pipes. Two of the grouting anchor pipes are inclined at 7-10° and two are inclined at 10-20°. They are set in pairs. The anchor pipes are embedded in 100cm long and 2...

Embodiment 3

[0093] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1-Figure 3 As shown, further, in order to better realize the present invention, the step S23 specifically includes the following steps:

[0094] Step S231: After the excavation of the upper step is 5-6m ahead of time, the lower pilot tunnel and the lower step will follow up in time; The stagger distance is not less than 2m, and the footage of each excavation is controlled within 2 steel frames, that is, not more than 1.6m. Operator operation;

[0095] Step S232: After the excavation, use C25 concrete spraying to seal the rock surface;

[0096] Step S233: Then set up a steel frame, and carry out anchor, net and spray system support. At the arch feet on both sides of the lower steps, corresponding to each primary support steel frame, four locking-foot grouting anchor pipes are installed. For setting, the anchor pipe is embedded with 100cm long and 25m diameter threaded steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com