Electric propelling engine gas distributor

A gas distributor and distributor technology, which is applied to machines/engines, mechanical equipment, thrust reversers, etc., can solve the problems of uneven plasma discharge, affecting discharge stability, uneven neutral particle environment, etc. The effect of uniform discharge and simple air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

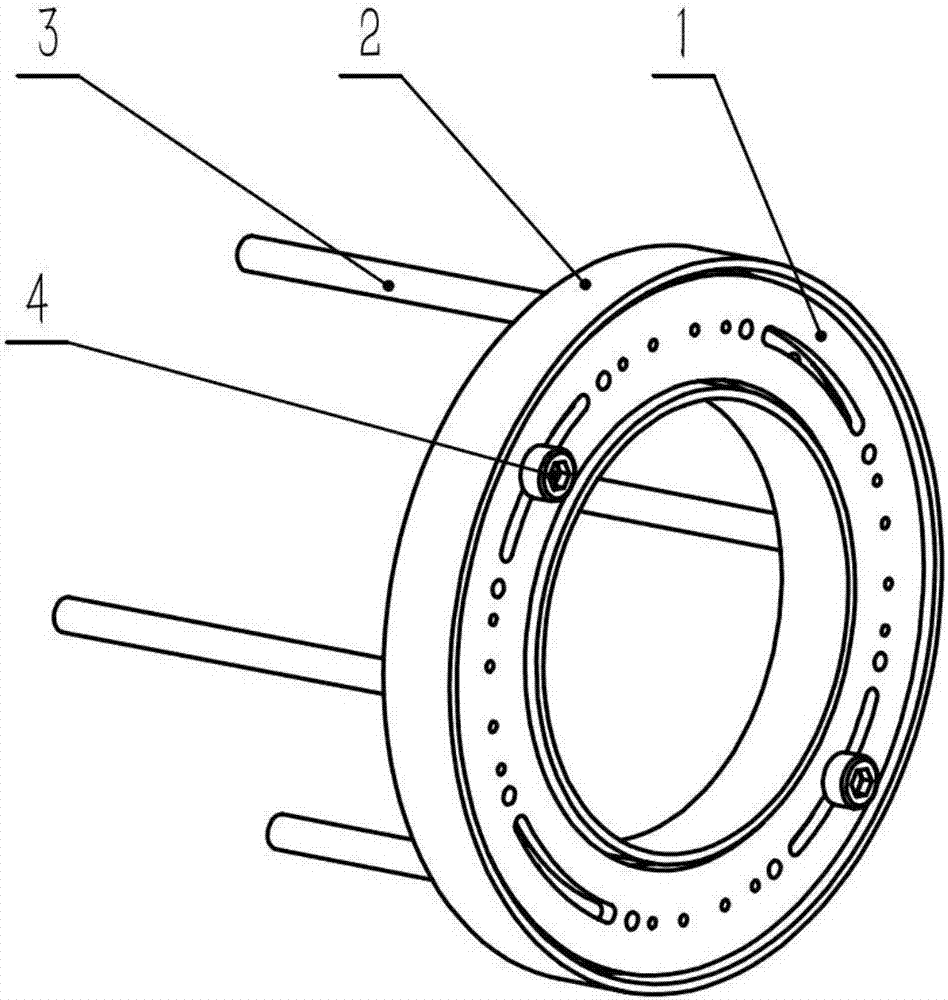

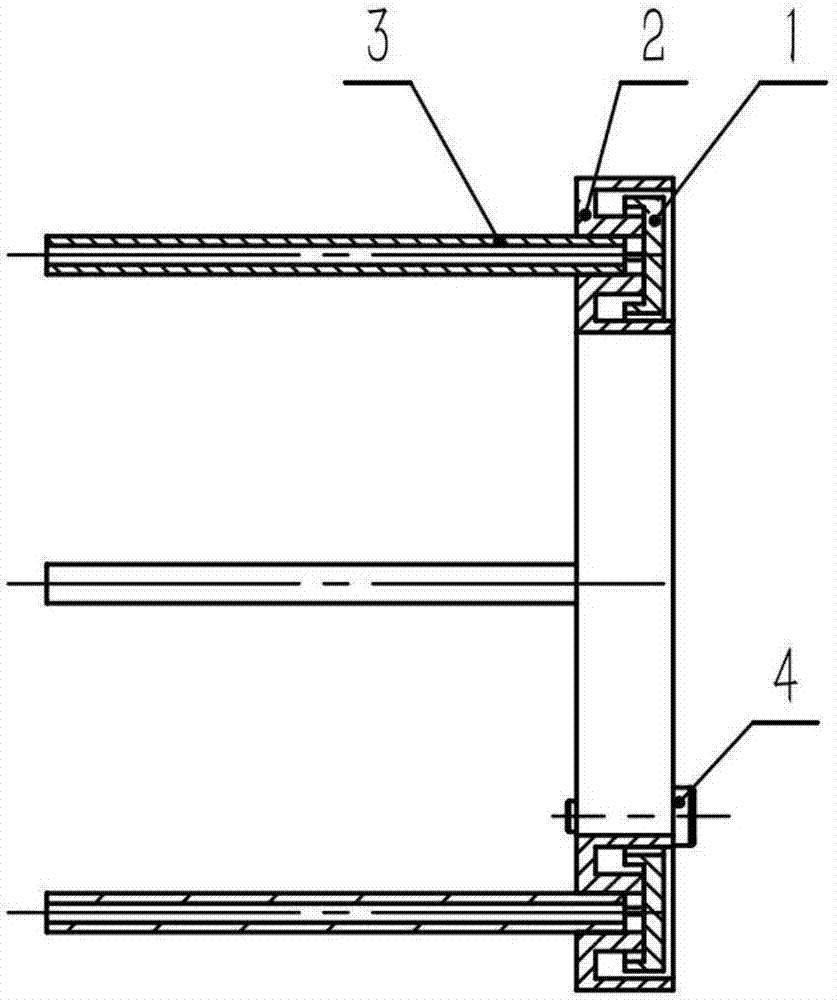

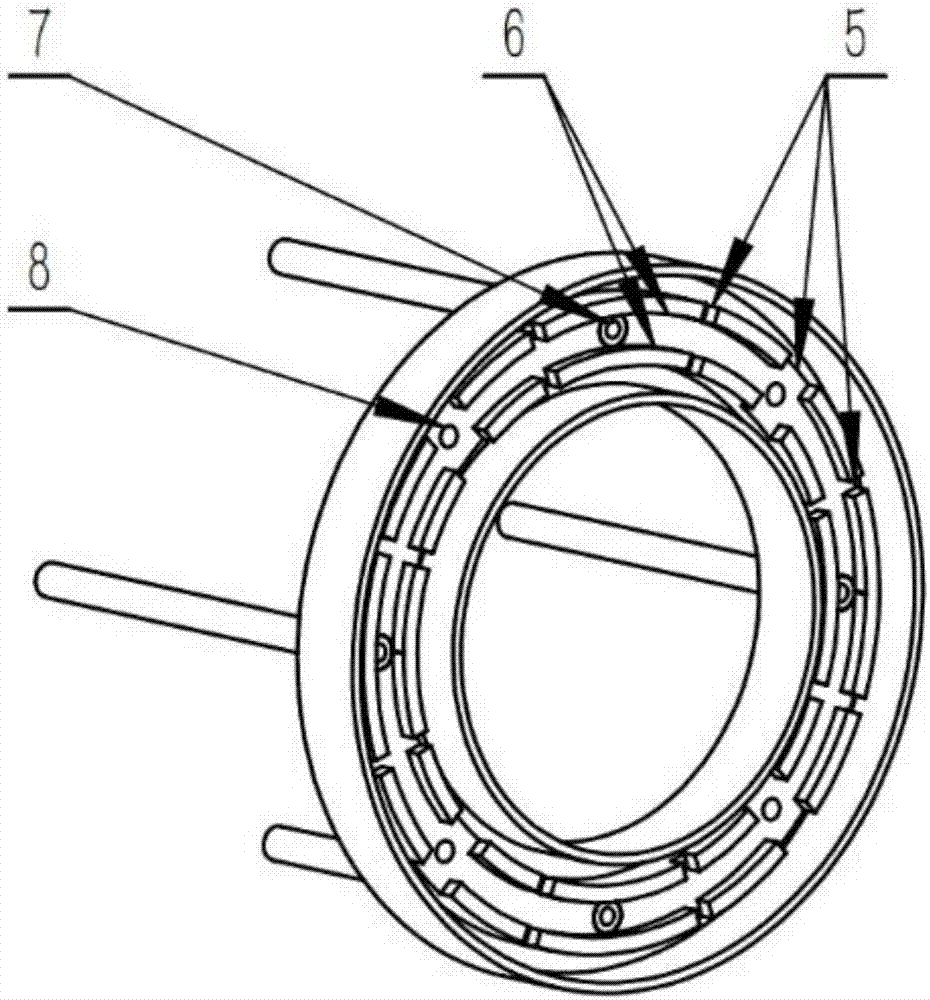

[0022] Attached below Figure 1~4 Specific embodiments of the present invention will be described.

[0023] The present invention is a gas distributor for an electric propulsion engine. The main components include distributor-upper bottom 1, distributor-lower bottom 2, air intake pipe 3, and fastening screw 4; wherein the distributor-lower bottom 2 has the following structure Features: radial air delivery groove 5, circumferential air delivery groove 6, air inlet hole 7, fastening threaded hole 8; distributor-upper bottom 1 has the following features: fastening screw positioning hole 9, axial air delivery groove 10 , 1mm axial air delivery hole 11, 0.6mm axial air delivery hole 12, 0.6mm axial air delivery hole 13.

[0024] Such as image 3 Shown is a distributor-bottom structure diagram of a gas distributor for an electric propulsion engine according to the present invention. Based on the distributor-lower bottom 2, weld and seal the four intake pipes 3 and the air intake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com