LED illuminating system based on refractive-diffractive hybrid

A LED lighting, refraction and mixing technology, applied in the field of lighting, can solve the problems that the lighting surface cannot achieve uniform lighting, sacrifice size and brightness advantages, and can not make full use of light energy, etc., to achieve simple and flexible design, wide application range, and light structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

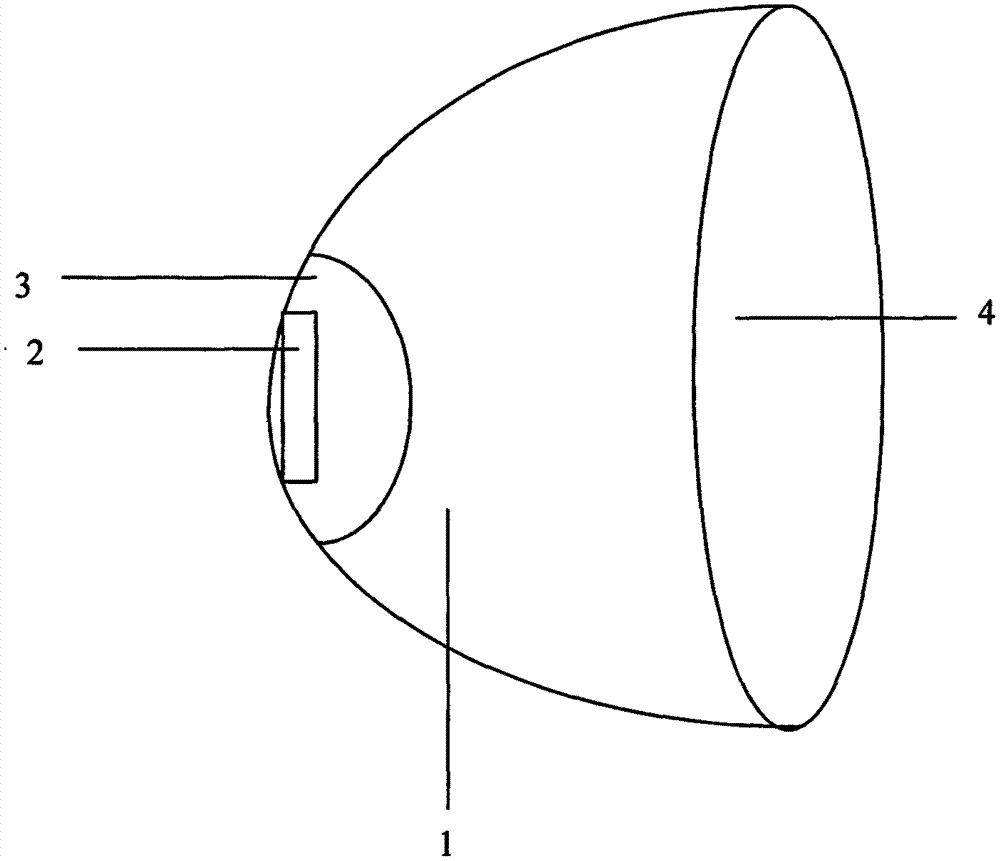

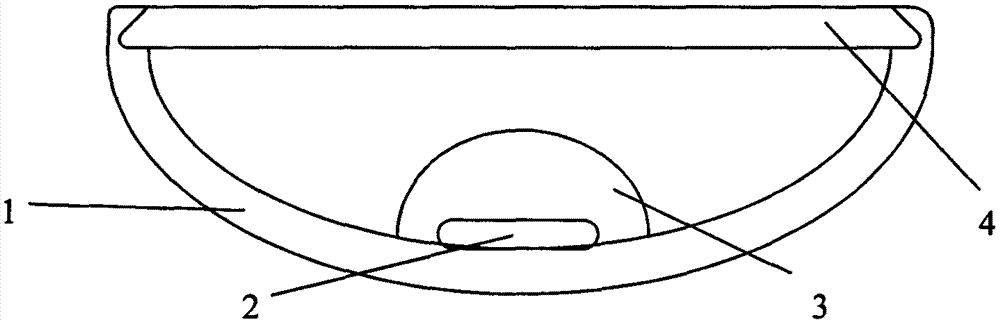

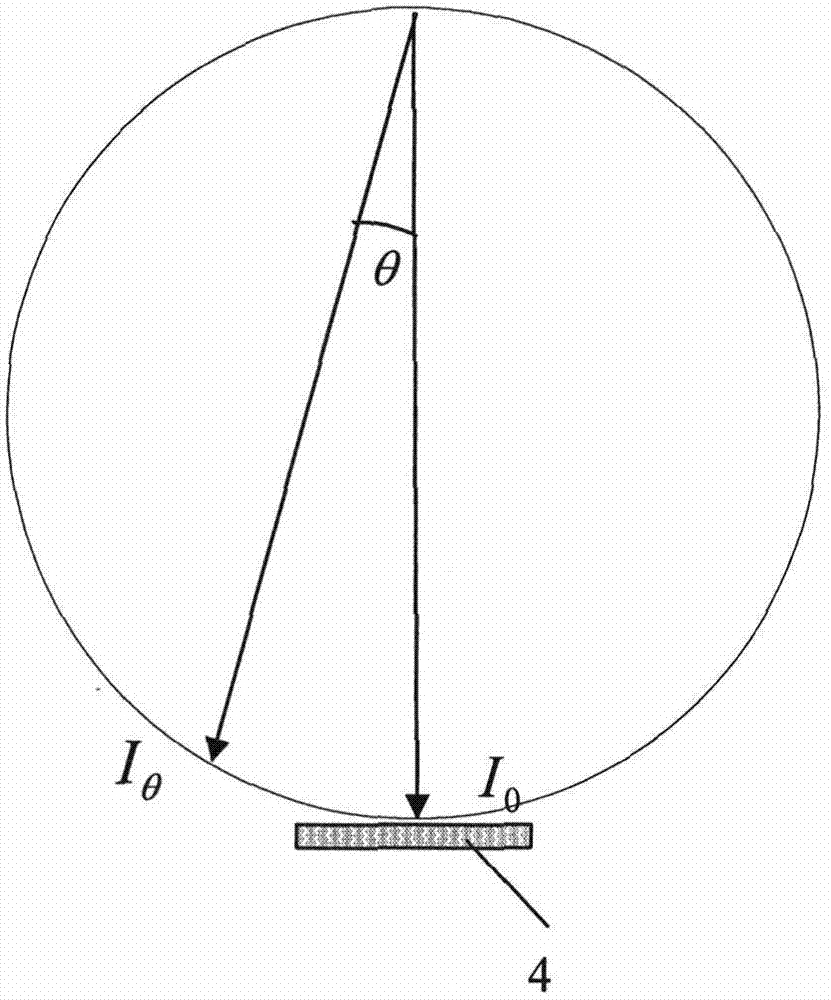

[0026] Such as figure 1 , 2 As shown, the single-chip refraction-diffraction hybrid LED lighting system includes a curved substrate 1 with high thermal conductivity, an LED chip 2 , a high refractive index convex lens 3 and a diffractive optical element 4 . The light emitted by the LED chip mounted on the curved substrate with high thermal conductivity is refracted by the lens, and part of the light is reflected by the curved substrate and incident on the diffractive optical element, finally achieving a uniform light intensity distribution on the lighting surface. Diffractive optical elements change the propagation direction, amplitude, phase and polarization state of light waves through phase modulation of incident light waves, which can control the propagation direction of light, improve lighting brightness, and achieve efficient lighting and uniform distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com