Gouache painting drying method and device

A drying device and gouache painting technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of gouache painting temperature damage, uneven heating, paper distortion, etc., to avoid high temperature damage and avoid drying. Uniform and uniform wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

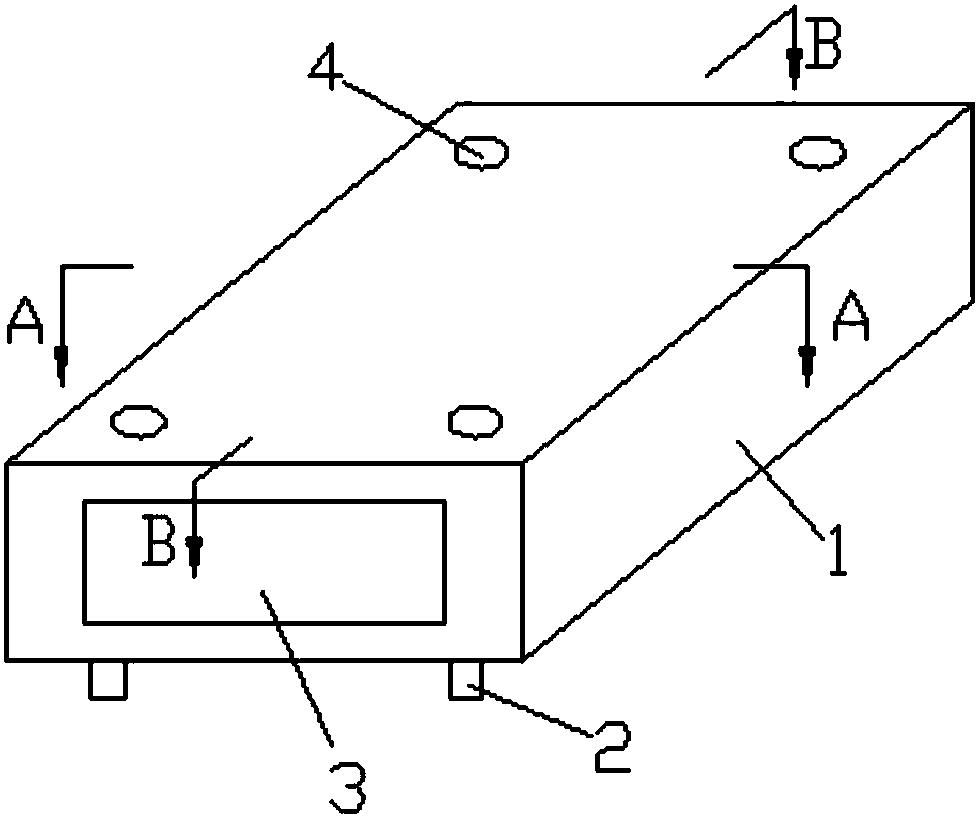

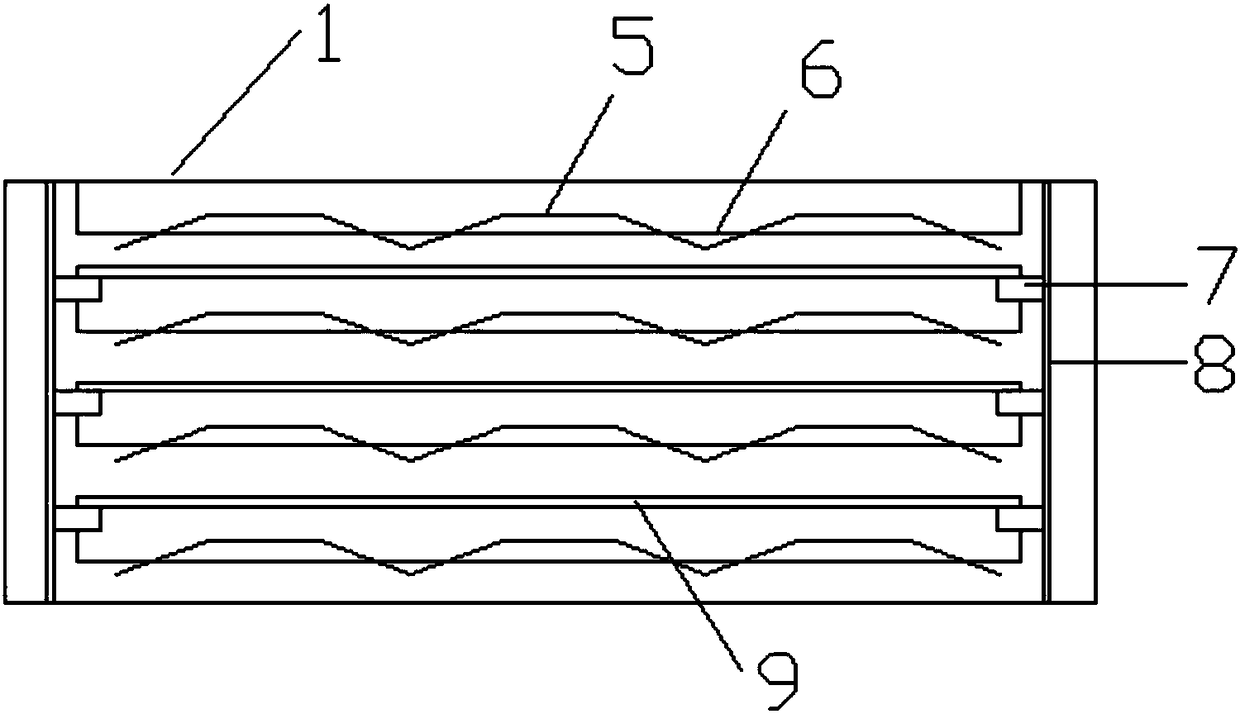

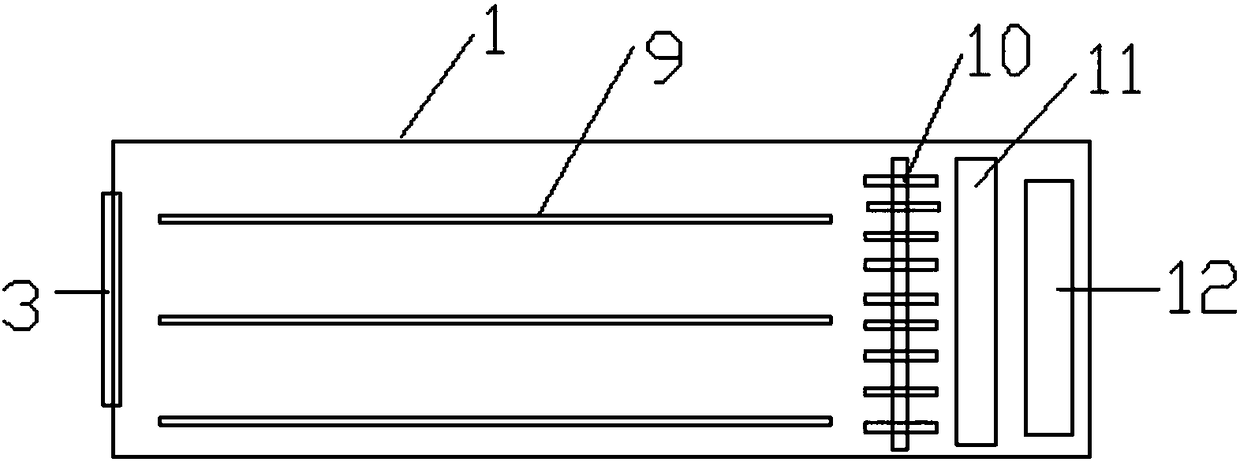

[0035] figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 Yes figure 1 A-A cross-sectional view, image 3 Yes figure 1 The B-B direction sectional view of the figure, combined with the accompanying drawings, it can be seen that the integrated dryer for drying gouache paintings includes an oven 1, and one side of the oven 1 is provided with an oven door 3 that can be opened and closed, and the oven door 3 A fan group 12 and an electric heat source group 11 are arranged on the opposite side of the wall, and the fan group 12 can blow the heat of the electric heat source group 11 into the oven 1, and several layers of drawing papers for fixing gouache paintings are arranged in the oven 1. Grid frame 9, described drawing paper fixing grid frame 9 can be pulled out from oven 1 and pushed in oven 1, and the air outlet side of described fan group 12 is provided with baffle plate 10, and described baffle plate 10 The wind blown out by th...

Embodiment 2

[0052] This embodiment discloses a gouache painting drying device with another structural form. The difference between it and Embodiment 1 is that, in order to obtain a uniform wind speed in Embodiment 1, baffles are used, while in this embodiment, a baffle is formed in an oven. A slow flow area, so that the air flow can enter the drying area in a laminar flow, so as to ensure that the air flow will not cause fluctuations in the vertical direction. At the same height, the flow rate of the air flow is consistent, specifically as Figure 4 As shown, including the oven, the oven is divided into four areas distributed sequentially along the airflow direction by three vertical partitions arranged vertically: the hot air area, the slow air area, the drying area, and the return air area, and the return air area passes through The dehumidification module communicates with the air inlet of the hot air area; wherein: a fan is arranged at the air inlet of the hot air area, and an electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com