Raw material ratio automatic control method of cement raw material batching system

A technology of cement raw meal and batching system, which is applied in the direction of various fluid ratio control, etc. It can solve the problems of long time lag, large fluctuations in the content of cement raw meal components, and the adjustment of cement raw material ratio is greatly affected by human subjective factors. To achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Take five kinds of cement raw materials as example.

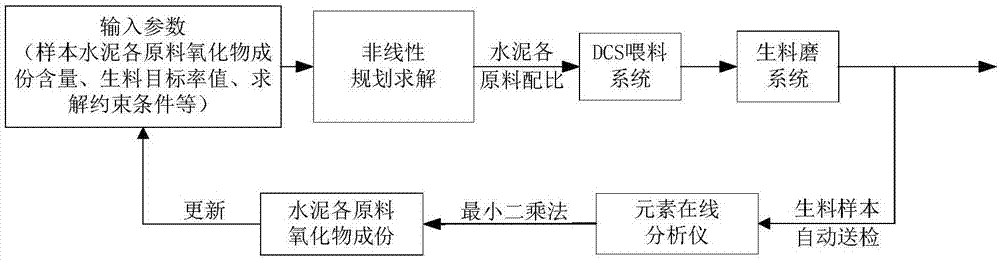

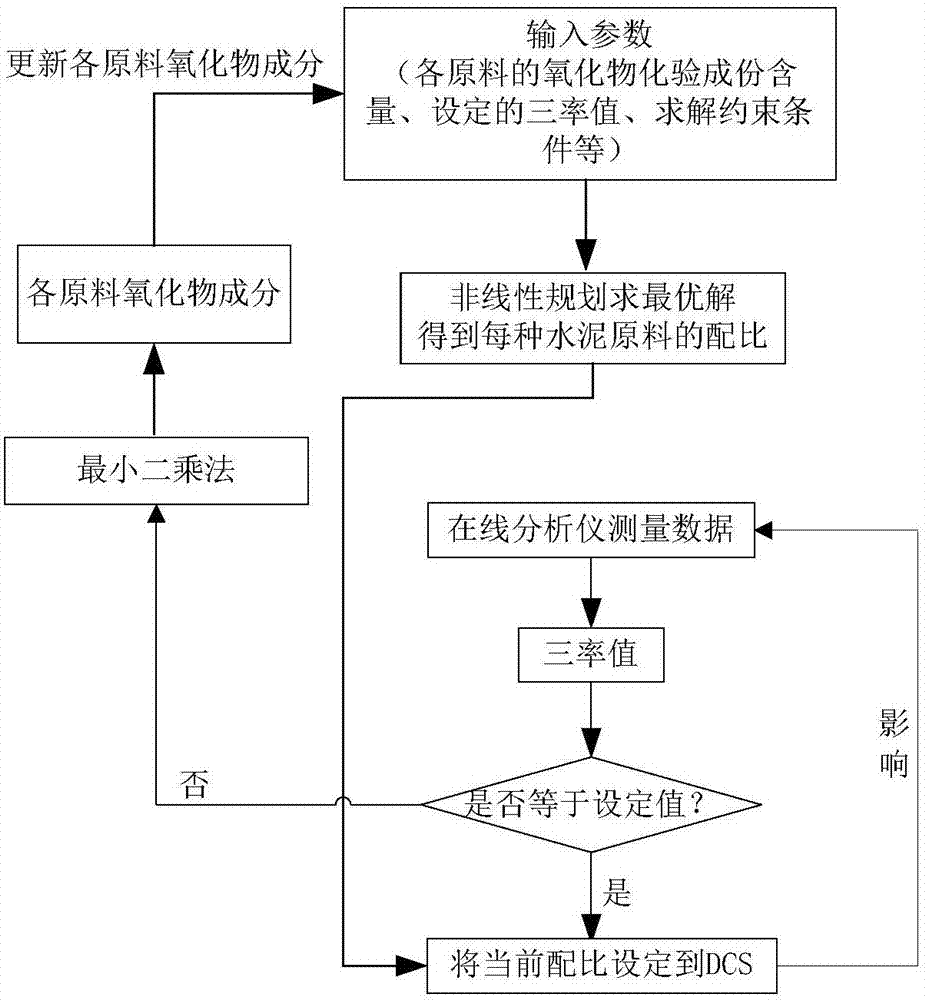

[0028] This method can automatically control the ratio of each raw material of cement in the actual production of a certain cement factory, figure 1 It is the control schematic diagram of this method, and the specific implementation scheme process is as follows figure 2 shown.

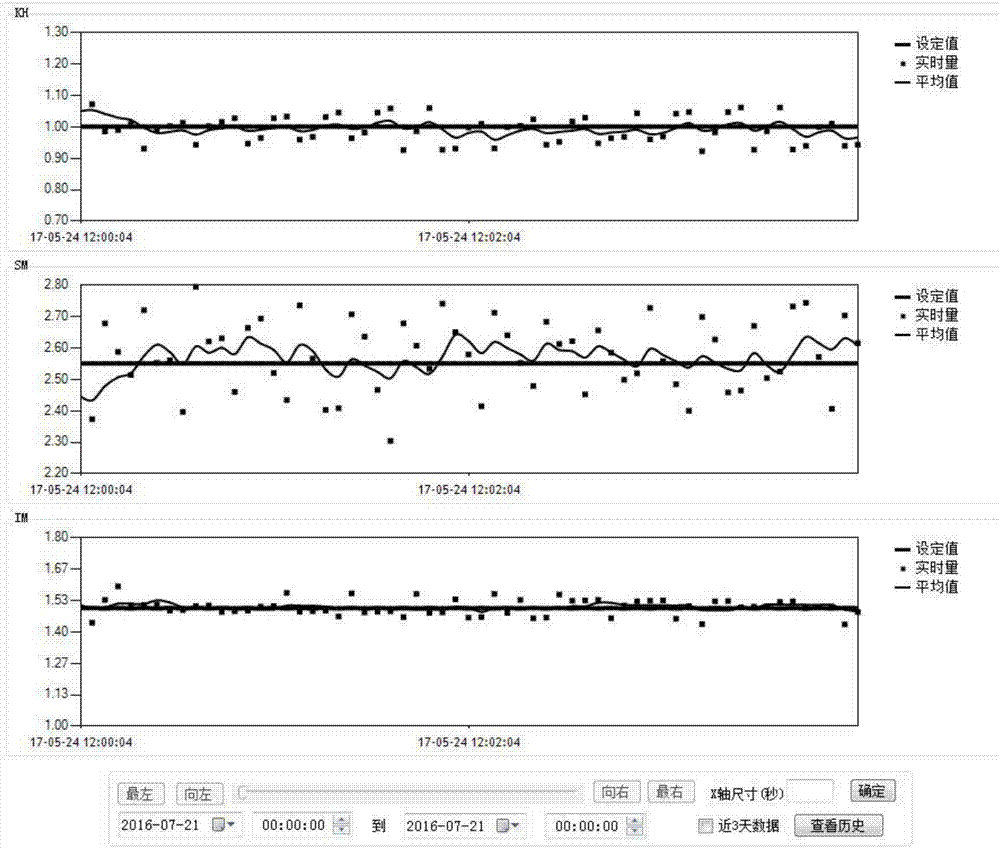

[0029] Step 1, first input the initial parameters of the system, which are provided by the laboratory of the cement factory. The initial parameters include the oxide components of the raw materials of the sample cement, and the target setting values of the cement raw material ratio (saturation ratio KH, silicon ratio SM, aluminum ratio IM) , the upper limit and lower limit of the ratio adjustment of each raw material of cement, the historical ratio data of each raw material of cement for 30 times (m=30), the target values of cement raw material ratio (KH, SM, IM) are 1.00, 2.55, 1.55 respectively, and the sample cement Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com