Method for taking out chip from package

A package and chip technology, applied in the direction of single semiconductor device testing, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as long time, inability to perform secondary bonding, aluminum PAD corrosion, etc., to reduce thermal damage, Avoid strong acid to corrode the chip, and the treatment effect is consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

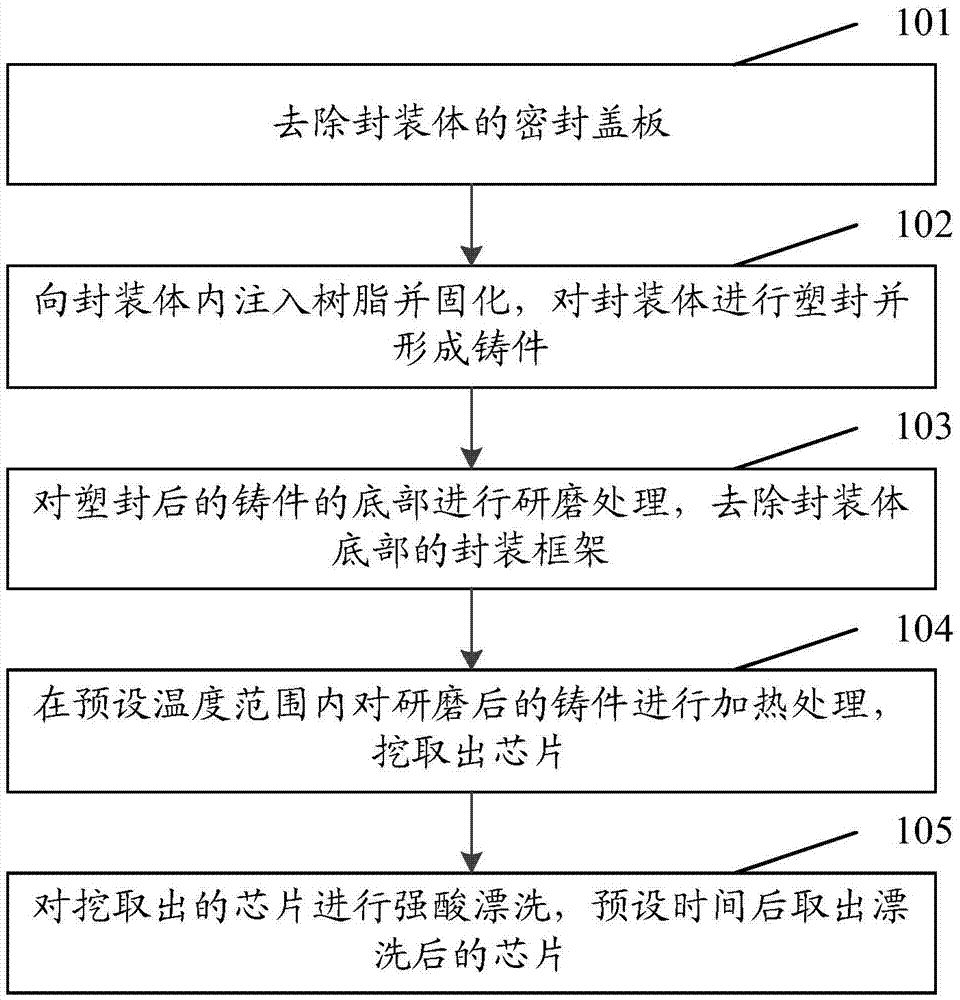

[0043] According to an embodiment of the present invention, a method for taking out a chip from a package is provided, figure 1 It is a flowchart of the method, specifically including steps 101-105:

[0044] Step 101 : remove the sealing cover of the package, the package frame is provided at the bottom of the package, and the chip is arranged on the package frame through the adhesive, and the sealing cover is provided on the upper part of the package.

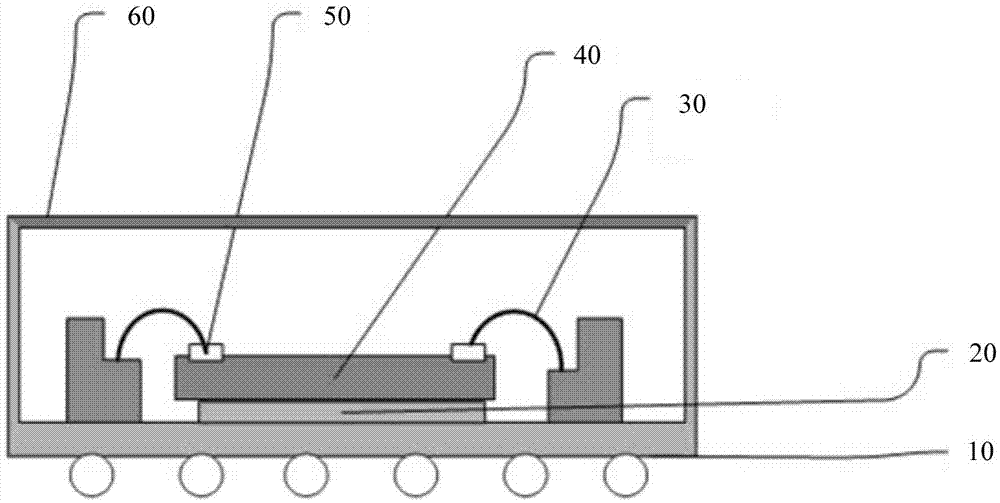

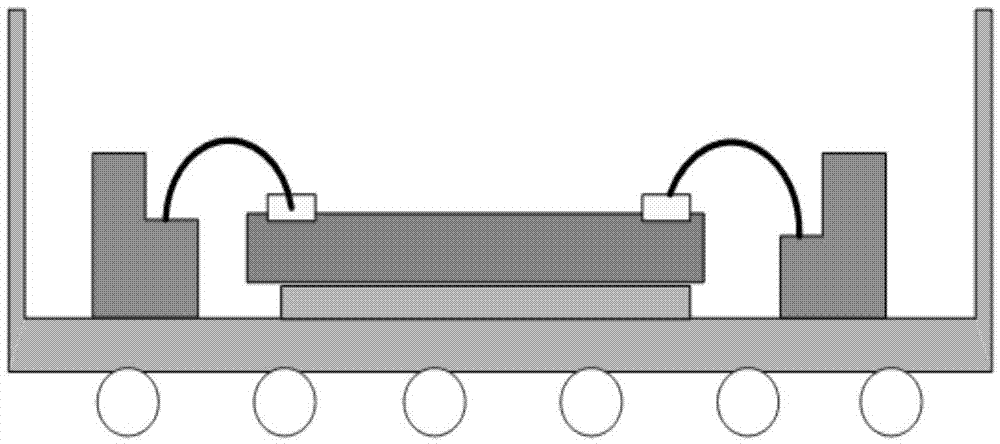

[0045] In the embodiment of the present invention, the package body adopts a metal or ceramic package frame 10 , and the die-bonding adhesive 20 can specifically adopt silver paste, eutectic solder, or conductive adhesive. For details, see figure 2 As shown, the pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com