Method and device for treating aluminum waste water slag, products and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

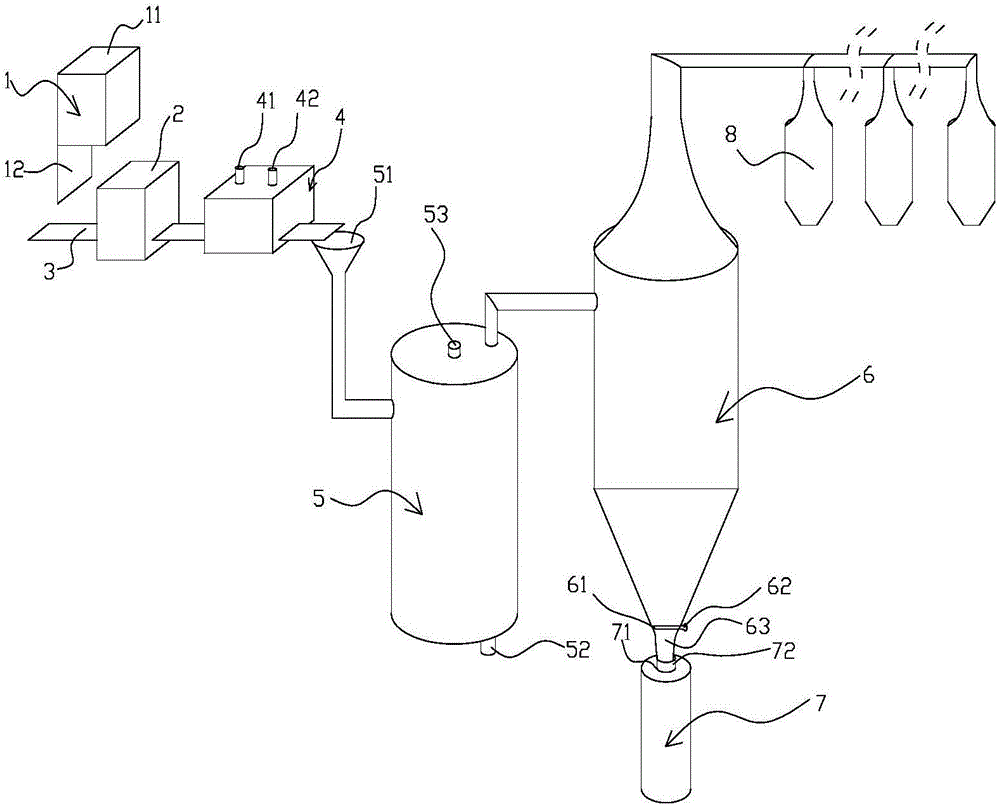

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

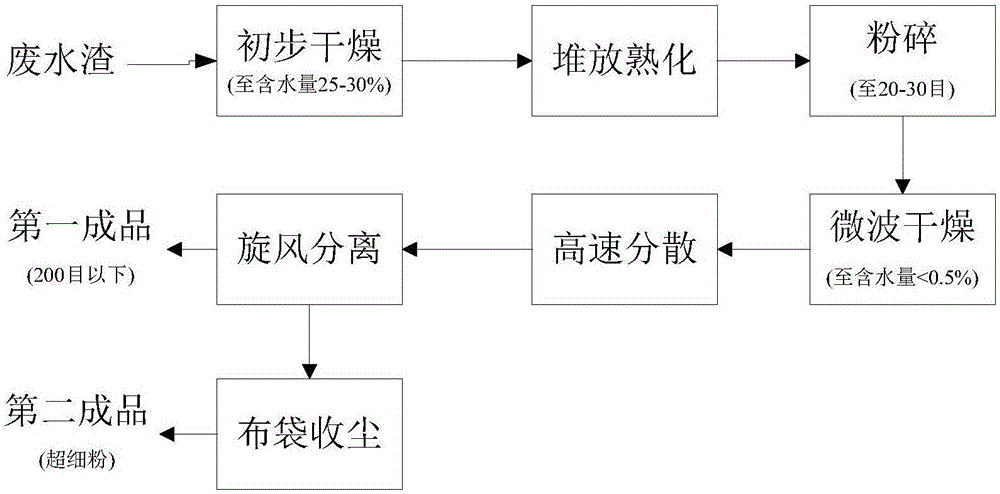

[0030] The invention provides a treatment method for aluminum waste water slag, the process flow chart is as follows figure 1 shown, including:

[0031] Preliminary drying step: preliminarily drying the waste water residue to a water content of 5-30%;

[0032] In this step, conventional methods can be used to rapidly dry the waste water slag. The drying methods include but are not limited to sun drying, hot air drying or rotary kiln drying. The most appropriate way; preferably, drying to a moisture content of 25-30%;

[0033] Stacking steps: Stack and mature the preliminarily dried waste water residue for 6-24 hours;

[0034] In this step, by stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com