Continuous production method of powdery and granular water-soluble ammonium polyphosphate

A water-soluble polymer production method technology, which is applied in the field of water-soluble fertilizer preparation, can solve the problems of unfavorable continuous product removal and inability to achieve continuous large-scale production, so as to overcome the difficulty of continuous material discharge, large production capacity, and chelation powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

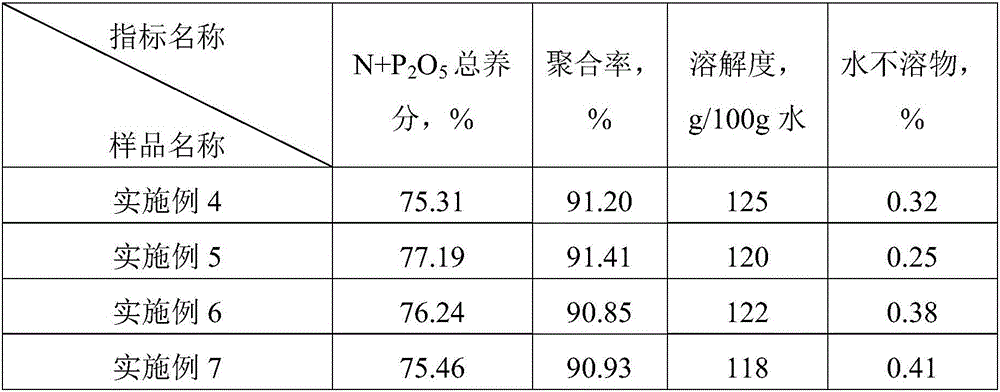

Examples

Embodiment 1

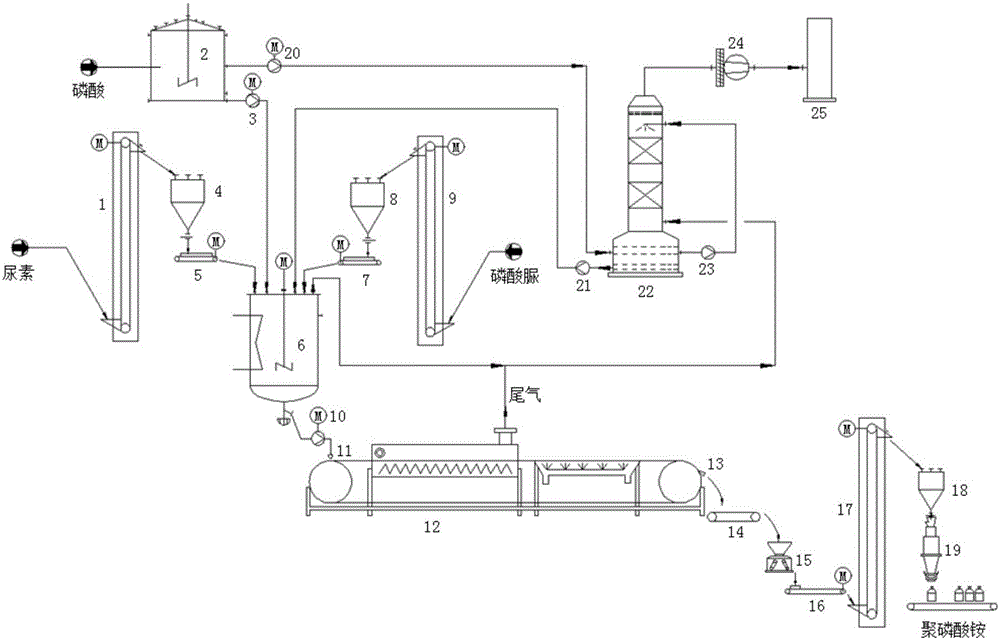

[0043] A continuous production method of powdery water-soluble ammonium polyphosphate, the method specifically comprises the following steps:

[0044] 1) Pre-polymerization: Add phosphoric acid and urea to the pre-polymerizer 6 at a molar ratio of 1:1, and react at 140°C for 2 minutes to obtain liquid materials;

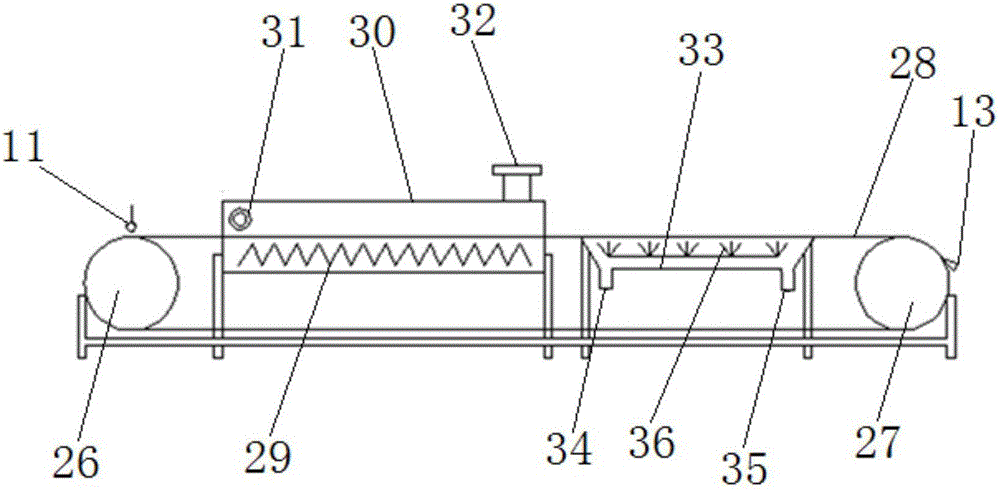

[0045] 2) Thermal polymerization and cooling: the liquid material is fed into the belt polymerizer 12 equipped with a heating zone and a cooling zone at a uniform speed. The temperature of the material in the heating zone is 170°C, and the residence time of the material in the heating zone is 30 minutes; the temperature of the circulating cooling water in the cooling zone is 12°C, and the residence time of the material in the cooling zone is 60 minutes. , to obtain solid material;

[0046] 3) Crushing: After the solid material is broken, the powdery water-soluble ammonium polyphosphate is obtained.

[0047] In step 2), such as figure 1 As shown, the belt polymeriz...

Embodiment 2

[0055] A continuous production method of powdery water-soluble ammonium polyphosphate, the method specifically comprises the following steps:

[0056] 1) Prepolymerization: Add urea phosphate and urea to the prepolymerizer 6 at a molar ratio of 1:1.5, and react at 60°C for 10 minutes to obtain liquid materials;

[0057] 2) Thermal polymerization and cooling: the liquid material is fed into the belt polymerizer 12 equipped with a heating zone and a cooling zone at a uniform speed. The temperature of the material in the heating zone is 220°C, and the residence time of the material in the heating zone is 5 minutes; the temperature of the circulating cooling water in the cooling zone is 7°C, and the residence time of the material in the cooling zone is 3 minutes. , to obtain solid material;

[0058] 3) Crushing: After the solid material is broken, the powdery water-soluble ammonium polyphosphate is obtained.

Embodiment 3

[0060] A continuous production method of powdery water-soluble ammonium polyphosphate, the method specifically comprises the following steps:

[0061] 1) Prepolymerization: Phosphorus sources (including phosphoric acid and urea phosphate) and urea were added to the prepolymerizer 6 at a molar ratio of 1:1.2, and reacted at 100°C for 5 minutes to obtain liquid materials;

[0062] 2) Thermal polymerization and cooling: the liquid material is fed into the belt polymerizer 12 equipped with a heating zone and a cooling zone at a uniform speed. The temperature of the material in the heating zone is 140°C, and the residence time of the material in the heating zone is 60 minutes; the temperature of the circulating cooling water in the cooling zone is 37°C, and the residence time of the material in the cooling zone is 30 minutes. , to obtain solid material;

[0063] 3) Crushing: After the solid material is broken, the powdery water-soluble ammonium polyphosphate is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com