Method for preparing dimethylsulfamoyl chloride

A technology for dimethylaminosulfonyl chloride and dimethylaminosulfonyl chloride is applied in the field of preparing dimethylaminosulfonyl chloride, can solve the problems of not conforming to the concept of green chemistry, unsuitable for large-scale production, high production cost, etc., and avoids hydrogen chloride The effect of gas, saving production cost and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

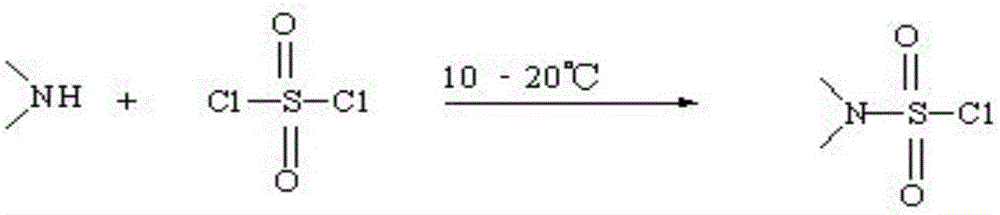

Method used

Image

Examples

Embodiment 1

[0015] Throw sulfuryl chloride into a 2L three-necked flask, set up buffer devices front and back, and seal the rear part with water, cool down to 10-20°C in a water bath, feed dimethylamine into the system, the system releases heat, and keep the temperature at 40-50°C. The maximum temperature is below 60°C. Weigh with electronic balance, stop feeding at 440g (ventilation time 4h) and continue stirring, stop reaction after 10min (420g weight increase in the actual weighing reaction bottle), oil bath slowly heats up, reflux overnight at 75°C (during the system heating process, salt Slowly dissolve and clarify, there is a large amount of acid gas, and the system is still clarified, weighing 1000g, distilling at 80°C-90°C under normal pressure to obtain about 200g fractions, and 650g product with a purity of 96% by water pump vacuum distillation. No solid was precipitated during the distillation process, and the final residue was 140 g, calculated as dimethylamine, with a molar y...

Embodiment 2

[0017] Throw sulfuryl chloride into a 2L three-necked flask, set buffer devices front and rear, liquid seal the rear, cool the ice salt to 0-10°C, feed dimethylamine into the system, the system releases heat, and keep the temperature at 40-50°C. The maximum temperature is below 50°C. Weigh with electronic balance, stop feeding at 440g (ventilation time 4h) and continue stirring, stop reaction after 10min (420g weight increase in the actual weighing reaction bottle), oil bath slowly heats up, reflux overnight at 75°C (during the system heating process, salt Slowly dissolve and clarify, there is a large amount of acid gas, and the system is still clarified, weighed 1100g, distilled at 80°C-90°C under normal pressure, and obtained about 150g of fractions, and 800g of product was obtained by water pump vacuum distillation, with a purity of 97.2%. No solid was precipitated during the distillation process, and the final residue of 120 g was calculated as dimethylamine, and the molar...

Embodiment 3

[0019] Throw sulfuryl chloride into a 2L three-necked flask, set up buffer devices front and back, and seal the rear with liquid, cool the ice salt to 0-10°C, feed dimethylamine into the system, the system will release heat, and keep the temperature at 10-20°C. The maximum temperature is below 30°C. Weigh with electronic balance, stop feeding at 440g (ventilation time 4h) and continue stirring, stop reaction after 10min (420g weight increase in the actual weighing reaction bottle), oil bath slowly heats up, reflux overnight at 75°C (during the system heating process, salt Slowly dissolve and clarify, there is a large amount of acid gas, and the system is still clarified, weighed 1384g, and distilled at 80°C-90°C under normal pressure to obtain about 71g of fractions, and 1116g of product was obtained by water pump vacuum distillation with a purity of 98%. No solid was precipitated during the distillation process, and the final residue was 93g, calculated as dimethylamine, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com