A kind of battery thermal runaway protection and its preparation method and mold

A technology for protection and thermal runaway, applied in battery pack components, isolation of batteries from their environment, electrical components, etc., can solve the problems of high cavity strength and sealing performance requirements, unsatisfactory flame retardant effect, cumbersome process, etc. The casting method is simple and easy to implement, preventing the spread of thermal runaway, and improving the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

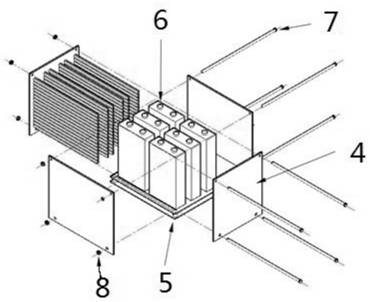

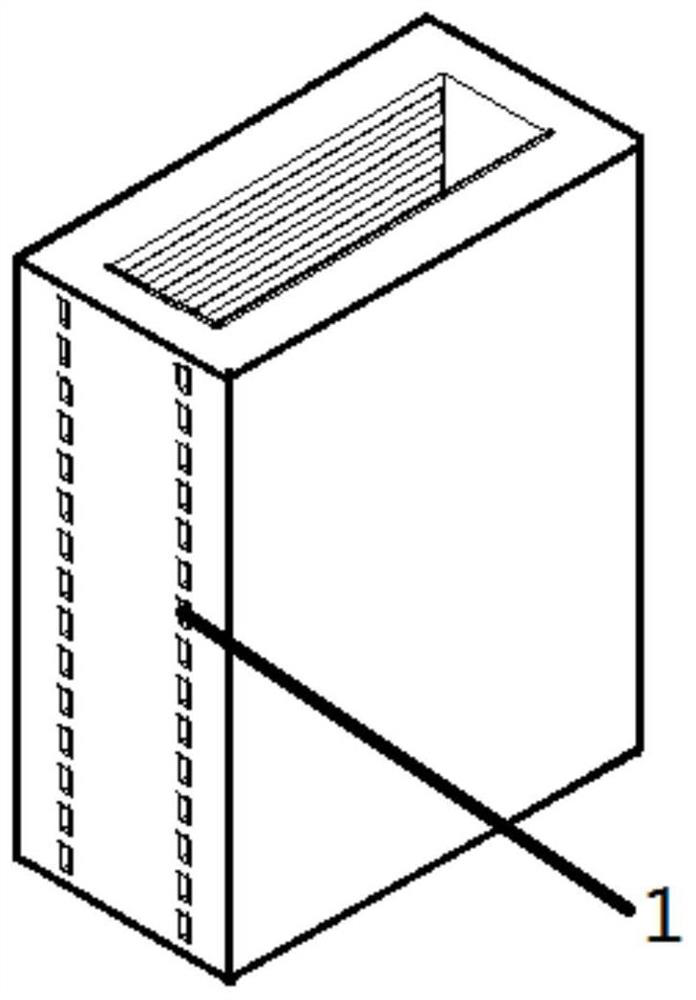

[0042] like Figure 1-3 As shown, it is a structural schematic diagram of a battery thermal runaway protection part and its preparation method and mold provided by the present invention. The protection part can be composed of one or more heat insulation units, and the combination method can be determined according to actual needs. The heat insulation unit It is in the shape of a cuboid, and the cuboid is a cuboid frame with a group of parallel plane openings. A channel 1 parallel to the axial direction of the heat insulation unit is arranged in a group of side walls opposite to the cuboid. The wall is perpendicular to the wall; the side wall of the cuboid is a laminated structure, and the laminated structure includes an outer layer, a middle layer and an inner layer, wherein the outer layer is a heat insulation board, the middle layer is a flame retardant board, and the inner layer is a pouring frame.

[0043]The heat insulation unit is equipped with a temperature alarm to ala...

Embodiment 2

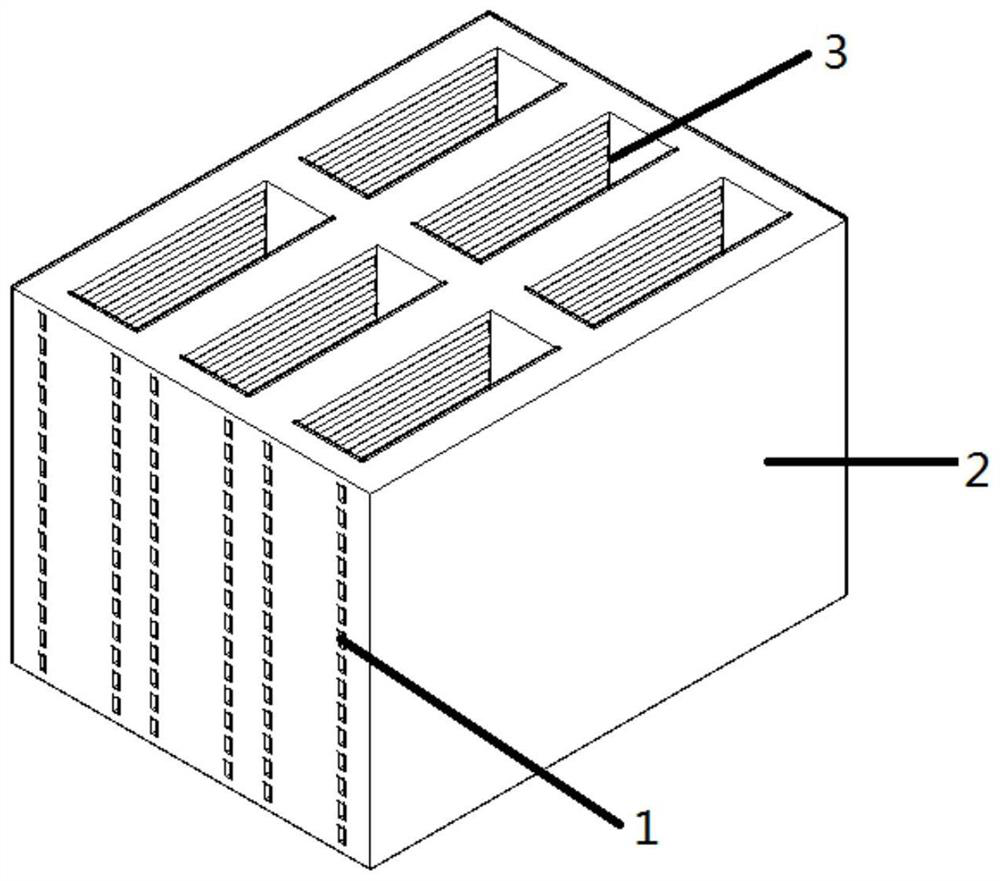

[0050] like image 3 As shown, it is a schematic diagram of the mold structure for preparing the inner pouring frame of the battery protection part. The mold is made of stainless steel or other metals with a melting point higher than 500 °C or their alloys, including: four surrounding plates 4, and a bottom plate 5 perpendicular to the surrounding plates 4 , battery model 6, and bolts 7 and nuts 8 used around.

[0051] Among them, the coaming plate 4 is welded by 90 cuboid steel bars and a steel plate, and the welding spacing and distribution of the steel bars are as follows: Figure 4 shown. Two symmetrical round holes matched with bolt 7 and nut 8 are opened on the left and right sides of one of the coaming plate 4 tops, and two round holes matched with bolt 7 and nut 8 are opened left and right symmetrically below.

[0052] Among them, the four coaming plates 4 are all steel plates with the same thickness, and two left and right symmetrical round holes are opened on the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com