Improvement method for laying film below coastal saline-alkali soil plough layer for salt resistance

A technology for saline-alkali soil and film laying, which is applied in the fields of land preparation methods, botanical equipment and methods, plant protection covers, etc. High cost and other problems, to achieve the effect of improving soil structural properties and crop root growth environment, ensuring crop growth, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

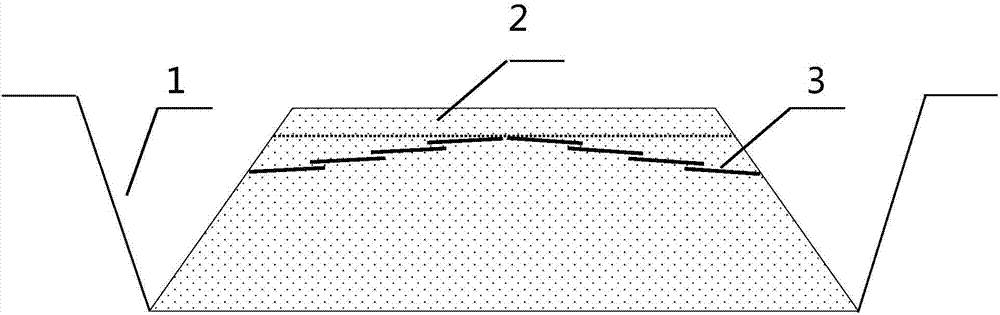

[0038] A salt-resistance improvement method of laying film under the plow layer of coastal saline-alkali soil,

[0039] Experimental plot: a village in Wudi County, Binzhou City, Shandong Province, the land is a severe saline-alkali land with a soil salt content of 0.98wt%.

[0040] Specific steps are as follows:

[0041] (1) Site preparation and film laying materials and size selection: build a strip field with a width of 20m and a length of 500m, and dig a salt and alkali drainage ditch around the strip field with a depth of 1.5m, an upper mouth of 2-3m, and a bottom width of 0.5-1m , rotary tillage and leveling; the material for paving the film is HDPE geomembrane coiled material (produced by Shandong Tianhe Plastic Co., Ltd.), with a width of 260cm, a film thickness of 0.5mm, and a service life of ≥50 years.

[0042] (2) Selection of film-laying method and setting of film-laying tendency and direction: the saline-alkali content of the soil in strip fields is ≥0.6wt%, and ...

Embodiment 2

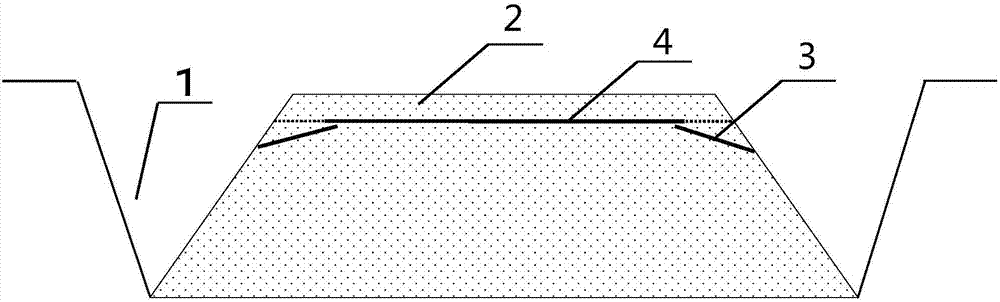

[0048] A salt-resistance improvement method of laying film under the plow layer of coastal saline-alkali soil,

[0049] Experimental plot: a village in Zhanhua County, Binzhou City, Shandong Province, where the land is moderately saline-alkali land with a soil salt content of 0.55wt%.

[0050] Specific steps are as follows:

[0051] (1) Site preparation and film laying materials and size selection: build a strip field with a width of 30m and a length of 500m, dig a salt and alkali drainage ditch around the strip field, the depth of the trench is 1.5m, the upper mouth is 2-3m, and the bottom width is 0.5-1m , rotary tillage and leveling; the material for paving the film is HDPE geomembrane coiled material (produced by Shandong Tianhe Plastic Co., Ltd.), with a width of 260cm, a film thickness of 0.5mm, and a service life of ≥50 years.

[0052] (2) Selection of film-laying method and film-laying tendency and direction setting: the saline-alkali content of the soil in the field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com