Tensioning rectification method and apparatus used for belt filter press

A technology of belt filter press and deviation correction device, which is applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of high manufacturing cost and maintenance cost, small change of filter tension force, and sensitivity of filter deviation correction Low-level problems, to achieve the effects of reducing equipment manufacturing costs and maintenance costs, reducing gas source consumption, and simplifying equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

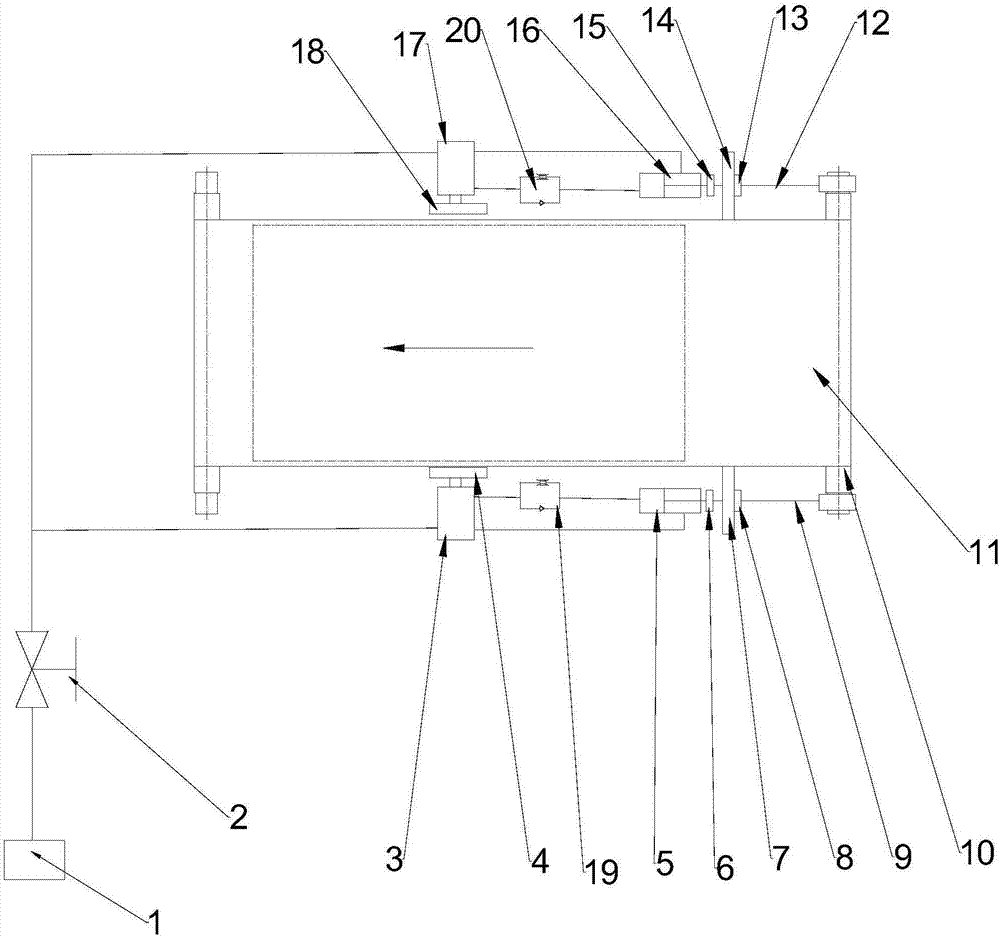

[0030] A kind of tension correction device that present embodiment is used for belt type filter press, such as figure 1 As shown, it includes a tensioning deviation adjustment roller 10, a left deviation correction mechanism and a right deviation correction mechanism, the tension deviation adjustment roller is arranged at one end of the filter screen, and the left deviation correction mechanism and the right deviation correction mechanism are symmetrically arranged on the left and right sides of the filter screen 11, and The left deviation correction mechanism and the right deviation correction mechanism are respectively connected with the left and right ends of the tensioning deviation adjustment roller, and the left deviation correction mechanism and the right deviation correction mechanism are respectively externally connected with an air source mechanism. Among them, along the conveying direction of the filter screen (as shown by the arrow in the figure), the tension adjust...

Embodiment 2

[0035] In this embodiment, a tension correction method for a belt filter press is realized through the tension correction device described in Embodiment 1. Unilateral expansion and contraction, adjust the tension of one side of the filter screen, so as to realize the rectification of the filter screen. For the biased side of the filter screen, by stretching the tension adjustment roller at this end, it will return to the original position after the deviation is corrected. Specifically:

[0036] (1) When the tension of the filter screen needs to be adjusted, the left and right deviation correction mechanisms drive both ends of the tension adjustment roller at the same time, so that the tension adjustment roller can move in translation along the conveying direction of the filter screen; adjust the filter screen When the tension is high, the specific process is as follows:

[0037] In the left correction mechanism, the compressed gas from the air source mechanism enters the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com