Anti-corrosion bottom valve screen net surface treatment method

A surface treatment and anti-corrosion technology, applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, etc., can solve the problems of restricting the development of pump bottom valves, damage, and poor anti-corrosion performance, and achieve long-term effective screening net, enhance activity, and prevent corrosion by corrosive substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

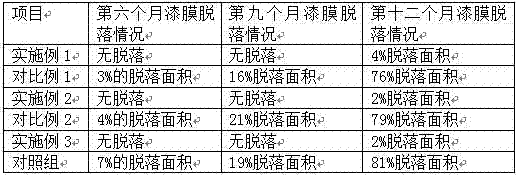

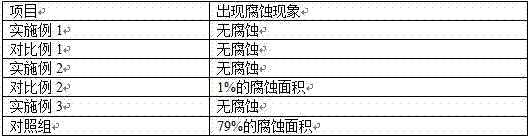

Embodiment 1

[0019] A surface treatment method for a corrosion-resistant bottom valve screen, comprising the following steps:

[0020] (1) Soak the bottom valve screen in the activation solution for 10 minutes, wherein the activation solution is made of the following components by weight: 16 parts of 3,5-dichloro-4-fluorobromobenzene, bromoacetaldehyde acetal 10 parts of diol, 35 parts of isopropanol;

[0021] (2) Immediately spray paint on the activated bottom valve screen, spray two coats of paint on the outer surface of the screen, and one coat of paint on the inner surface, wherein the paint is made of the following components by weight: silicone resin 60 parts, 5 parts of melamine cyanurate, 9 parts of disodium sebacate, 11 parts of silicon micropowder, 17 parts of polymethyl methacrylate, 0.5 parts of triethyl methanephosphonate, 2-fluoro-2-phosphorus 0.1 part of triethyl acyl acetate;

[0022] (3) Put the painted bottom valve screen into the oven, after drying, take it out, and le...

Embodiment 2

[0030] A surface treatment method for a corrosion-resistant bottom valve screen, comprising the following steps:

[0031] (1) Soak the bottom valve screen in the activation solution for 13 minutes, wherein the activation solution is made of the following components in parts by weight: 18 parts of 3,5-dichloro-4-fluorobromobenzene, bromoacetaldehyde acetal 12 parts of diol, 38 parts of isopropanol;

[0032] (2) Immediately spray paint on the activated bottom valve screen, spray two coats of paint on the outer surface of the screen, and one coat of paint on the inner surface, wherein the paint is made of the following components by weight: silicone resin 70 parts, 6 parts of melamine cyanurate, 11 parts of disodium sebacate, 12 parts of silicon micropowder, 19 parts of polymethyl methacrylate, 0.6 parts of triethyl methanephosphonate, 2-fluoro-2-phosphorus 0.2 parts of triethyl acyl acetate;

[0033] (3) Put the painted bottom valve screen into the oven, after drying, take it ...

Embodiment 3

[0041] A surface treatment method for a corrosion-resistant bottom valve screen, comprising the following steps:

[0042] (1) Soak the bottom valve screen in the activation solution for 15 minutes, wherein the activation solution is made of the following components by weight: 20 parts of 3,5-dichloro-4-fluorobromobenzene, bromoacetaldehyde acetal 13 parts of diol, 40 parts of isopropanol;

[0043] (2) Immediately spray paint on the activated bottom valve screen, spray two coats of paint on the outer surface of the screen, and one coat of paint on the inner surface, wherein the paint is made of the following components by weight: silicone resin 80 parts, 7 parts of melamine cyanurate, 13 parts of disodium sebacate, 13 parts of silicon micropowder, 20 parts of polymethyl methacrylate, 0.7 parts of triethyl methanephosphonate, 2-fluoro-2-phosphorus 0.3 parts of triethyl acyl acetate;

[0044] (3) Put the painted bottom valve screen into the oven, after drying, take it out, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com