A constant-frequency equal-energy control method for a micro-spark pulse power supply

A technology of pulse power supply and control method, which is applied in the direction of circuits, manufacturing tools, electric processing equipment, etc., can solve the problems that the consistency of single discharge energy is difficult to guarantee, the breakdown time of the discharge gap is not fixed, and the breakdown delay time is different. Achieve a lot of signal logic processing capabilities, improve material removal rate, and drive speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

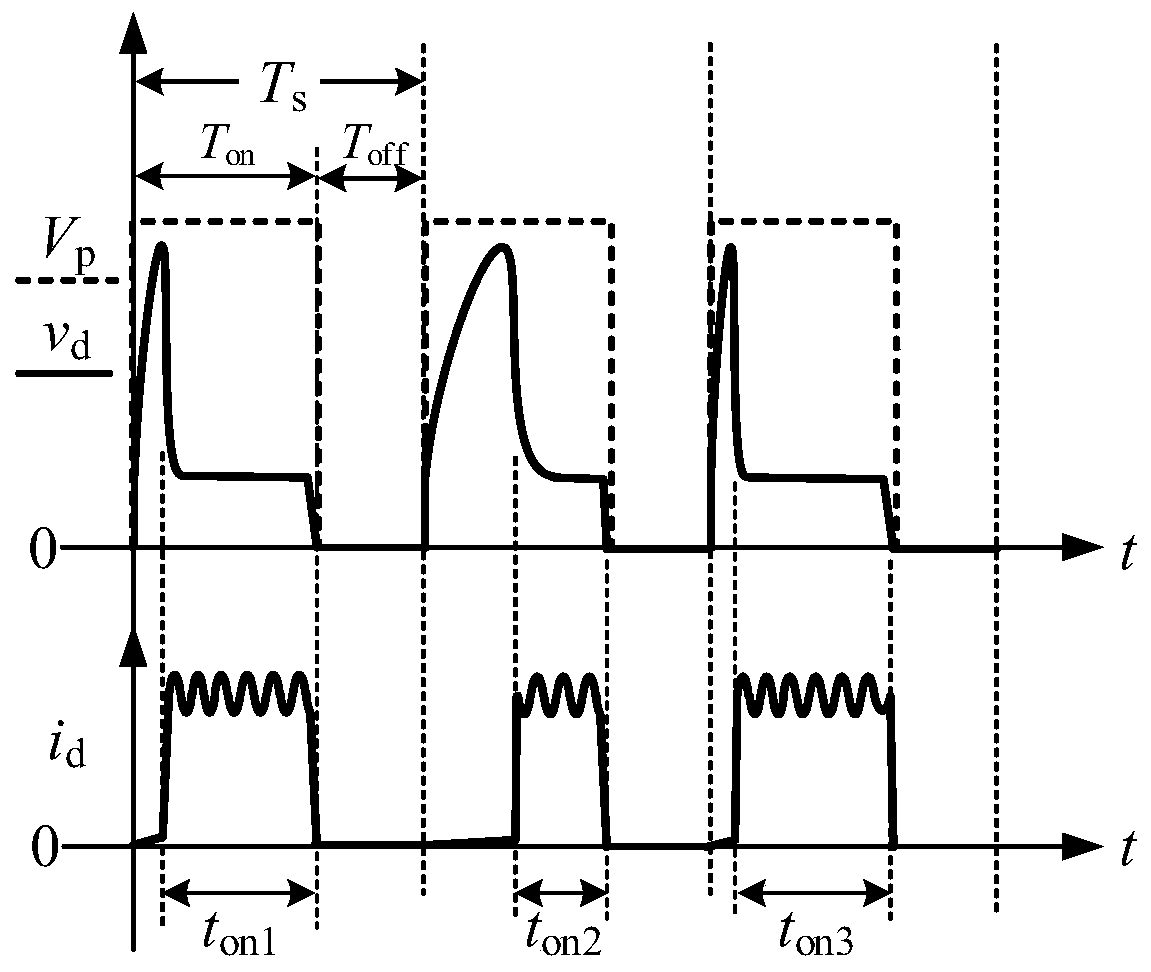

[0017] The solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] The energy control method such as the constant frequency of the micro-spark pulse power supply of the present invention is based on a high-speed hardware circuit. If the selected hardware bandwidth is too low, the response is too slow, and the delay is too long, this method cannot be realized. The following will first introduce Specific hardware circuit selection requirements.

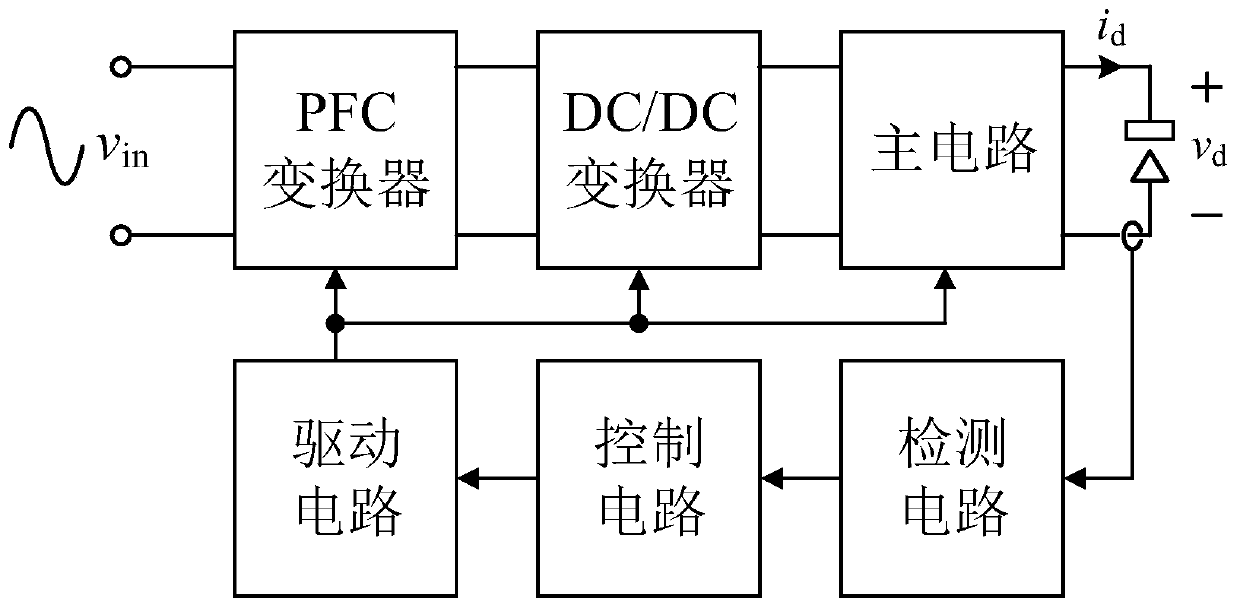

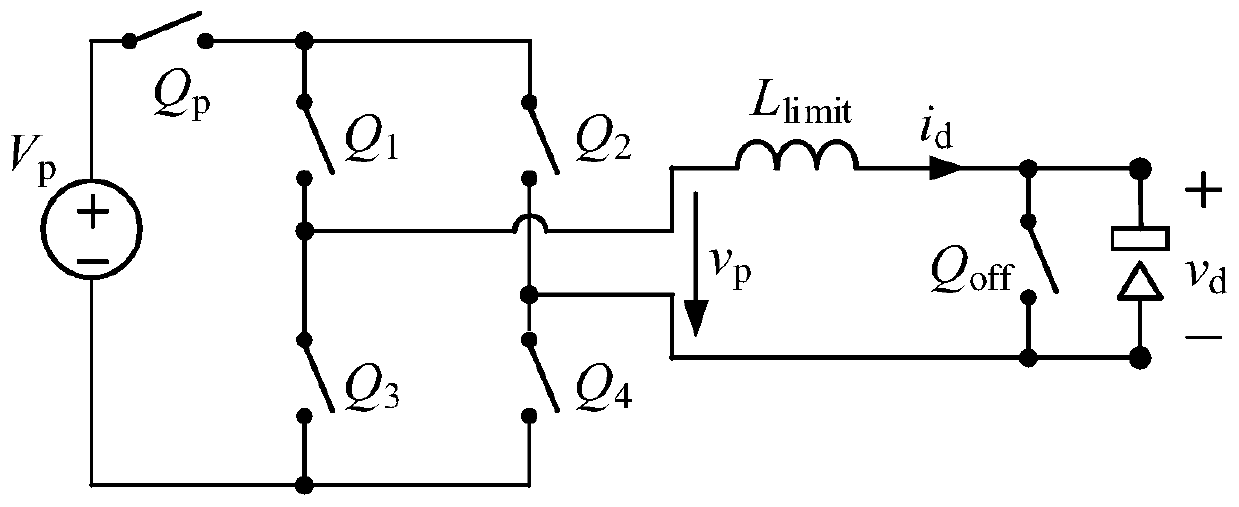

[0019] In order to reduce the interference between the various parts of the EDM machine tool system, the general pulse power supply takes power from the AC input alone. Traditional pulse power supplies mostly use low-frequency transformers and bridge rectifiers plus capacitors for rectification. The power supply has a large volume and low input power factor. In order to reduce the influence of parasitic parameters on processing, reduce the size of the power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com