Heat and sound insulation color steel plate

A heat and sound insulation, color steel plate technology, applied in the direction of layered products, natural mineral layered products, synthetic resin layered products, etc., can solve the problems of poor sound insulation effect, weak heat preservation function, etc., to reduce the overall weight, reduce Penetration of light to ensure the effect of the interior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

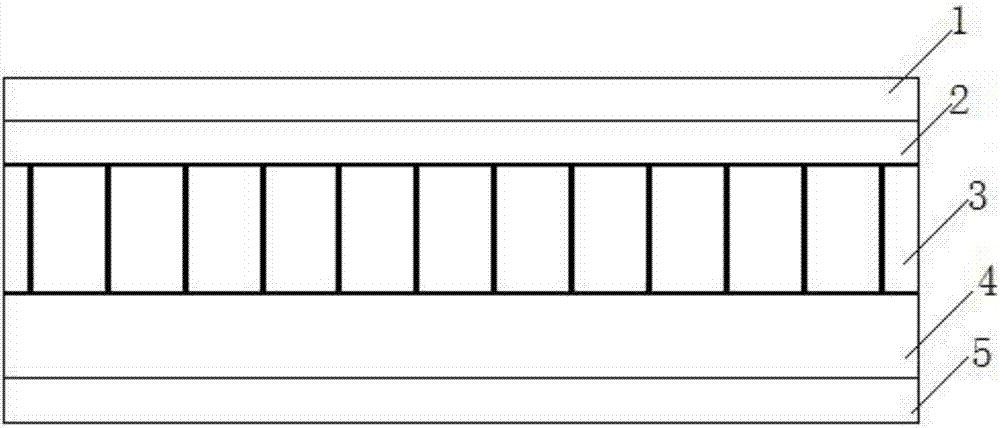

[0025] A heat-insulating and sound-insulating color steel plate, comprising an outer panel 1, an insulating layer 2, a hollow interior layer 3, a sound-absorbing asbestos layer 4, and an inner panel 5 glued in sequence, and the upper surface of the outer panel 1 is covered with a reflective foil film , the heat insulating layer 2 is an airgel layer, and the hollow interior layer 3 is a hollow sheet made by extrusion process, which is a composite material composed of polypropylene and glass fiber, wherein the weight percentage of glass fiber is 40 %, the weight percentage of polypropylene is 60%.

[0026] Both the outer panel 1 and the inner panel 5 are hot-dip galvanized steel sheets with a thickness of 15mm, the thickness of the reflective foil film is 3μm, the thickness of the heat insulation layer 2 is 30mm, the thickness of the hollow interior layer 3 is 40mm, and the thickness of the sound-absorbing asbestos layer 4 is 30mm.

Embodiment 2

[0028] A heat-insulating and sound-insulating color steel plate, comprising an outer panel 1, an insulating layer 2, a hollow interior layer 3, a sound-absorbing asbestos layer 4, and an inner panel 5 glued in sequence, and the upper surface of the outer panel 1 is covered with a reflective foil film , the heat insulation layer 2 is an airgel layer, and the hollow interior layer 3 is a hollow sheet made by extrusion process, which is a composite material composed of polypropylene and glass fiber, wherein the weight percentage of glass fiber is 35% %, the weight percentage of polypropylene is 50%, and the fine nanostructure of the fiber makes the thermal conductivity of the material extremely low. Therefore, the setting of the heat insulating layer 2 greatly improves the heat insulation and thermal insulation performance of the color steel plate.

[0029] Both the outer panel 1 and the inner panel 5 are hot-dip galvanized steel sheets with a thickness of 10mm, the thickness of t...

Embodiment 3

[0031] A heat-insulating and sound-insulating color steel plate, comprising an outer panel 1, an insulating layer 2, a hollow interior layer 3, a sound-absorbing asbestos layer 4, and an inner panel 5 glued in sequence, and the upper surface of the outer panel 1 is covered with a reflective foil film , the heat insulating layer 2 is an airgel layer, and the hollow interior layer 3 is a hollow sheet made by extrusion process, which is a composite material composed of polypropylene and glass fiber, wherein the weight percentage of glass fiber is 50 %, the weight percentage of polypropylene is 65%, and the fine nanostructure of the fiber makes the thermal conductivity of the material extremely low. Therefore, the setting of the heat insulating layer 2 greatly improves the heat insulation and thermal insulation performance of the color steel plate.

[0032] Both the outer panel 1 and the inner panel 5 are hot-dip galvanized steel sheets with a thickness of 20mm, the thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com