Preparing method of chromium trioxide and chromium trioxide crystal particle obtained through preparing method

A chromic anhydride, crystal technology, applied in the field of chromium chemical industry, can solve problems such as low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

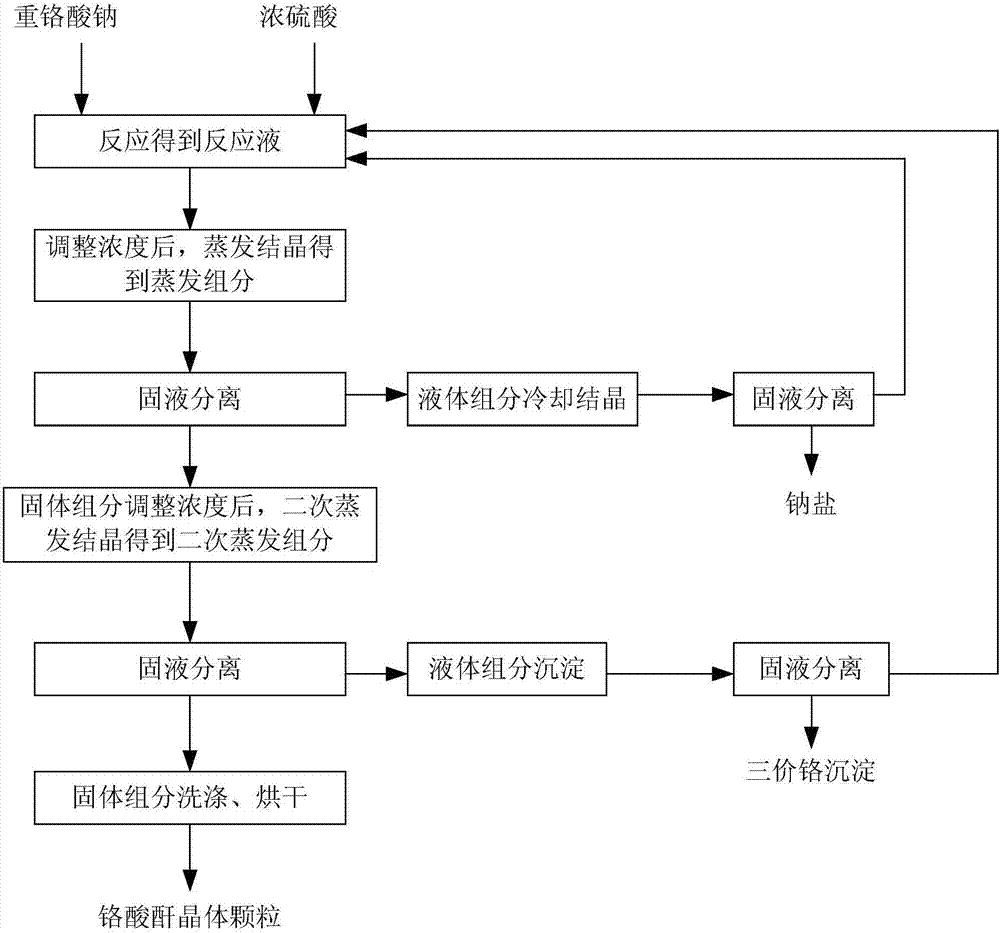

[0073] A clean preparation method for crystalline chromic anhydride, comprising the following steps:

[0074] (1) Add concentrated sulfuric acid dropwise or directly pour it into 10~70°Bé sodium dichromate solution, the molar ratio of sodium dichromate to concentrated sulfuric acid is 3:4~3:6.5, Na 2 Cr 2 o 7 React with acid, the reaction time is 5-50min, to obtain the reaction liquid;

[0075] (2) Add water or chromic anhydride solution to the reaction solution obtained in step (1) to adjust the concentration to the concentration to be crystallized (10-57°Bé), and evaporate at a vacuum degree of 0.05-0.1MPa and a temperature of 40-100°C Crystallization, evaporative crystallization time is 4-12h, and evaporated components are obtained;

[0076] During the evaporative crystallization process, the produced HCl, Cl 2 , CrO 2 Cl 2 Gas is sent to alkaline water for absorption;

[0077] (3) separating the evaporated components obtained in step (2) from solid to liquid;

[00...

Embodiment 1

[0087] (1) Add the concentrated sulfuric acid dropwise to 10 ° Bé sodium dichromate solution, the molar ratio of sodium dichromate and concentrated sulfuric acid is 3:4, Na 2 Cr 2 o 7 React with acid, the reaction time is 5min, obtain reaction solution;

[0088] (2) Add water or chromic anhydride solution to the reaction solution obtained in step (1) to adjust the concentration to 10 ° Bé, and conduct evaporation and crystallization at a vacuum of 0.1 MPa and a temperature of 60 ° C. The evaporation time is 6 hours to obtain the evaporation component ;

[0089] During the evaporative crystallization process, the produced HCl, Cl 2 , CrO 2 Cl 2 Gas is sent to alkaline water for absorption;

[0090] (3) separating the evaporated components obtained in step (2) from solid to liquid;

[0091] Add water to dissolve the solid component to 10°Bé, carry out secondary evaporation and crystallization at a vacuum degree of 0.1MPa and a temperature of 60°C, and evaporate for 6 hour...

Embodiment 2

[0098] (1) Add the concentrated sulfuric acid dropwise to 20°Bé sodium dichromate solution, the mol ratio of sodium dichromate to the concentrated sulfuric acid is 3:4.5, Na 2 Cr 2 o 7 React with acid, the reaction time is 10min, to obtain the reaction solution;

[0099] (2) In the reaction liquid that step (1) obtains, add water or chromic anhydride solution and adjust concentration to be 20 ° of B é, be that 0.09MPa, temperature carry out evaporative crystallization at 50 ℃ in vacuum tightness, add perchloric acid in evaporation process, evaporation time For 7h, the evaporated component was obtained;

[0100] During the evaporative crystallization process, the produced HCl, Cl 2 , CrO 2 Cl 2 Gas is sent to alkaline water for absorption;

[0101](3) separating the evaporated components obtained in step (2) from solid to liquid;

[0102] The solid component was dissolved in water to 20 ° Bé, and the second evaporation crystallization was carried out at a vacuum degree o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com