Method for treating heavy metal complex wastewater based on UV/chlorine advanced oxidation technology

An advanced oxidation technology and heavy metal technology, which is applied in the field of treatment of heavy metal complex wastewater based on UV/chlorine advanced oxidation technology, can solve problems such as poor effect of heavy metal complex wastewater, achieve large-scale engineering applications, and have a wide range of pH applications. , the effect of high photon yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

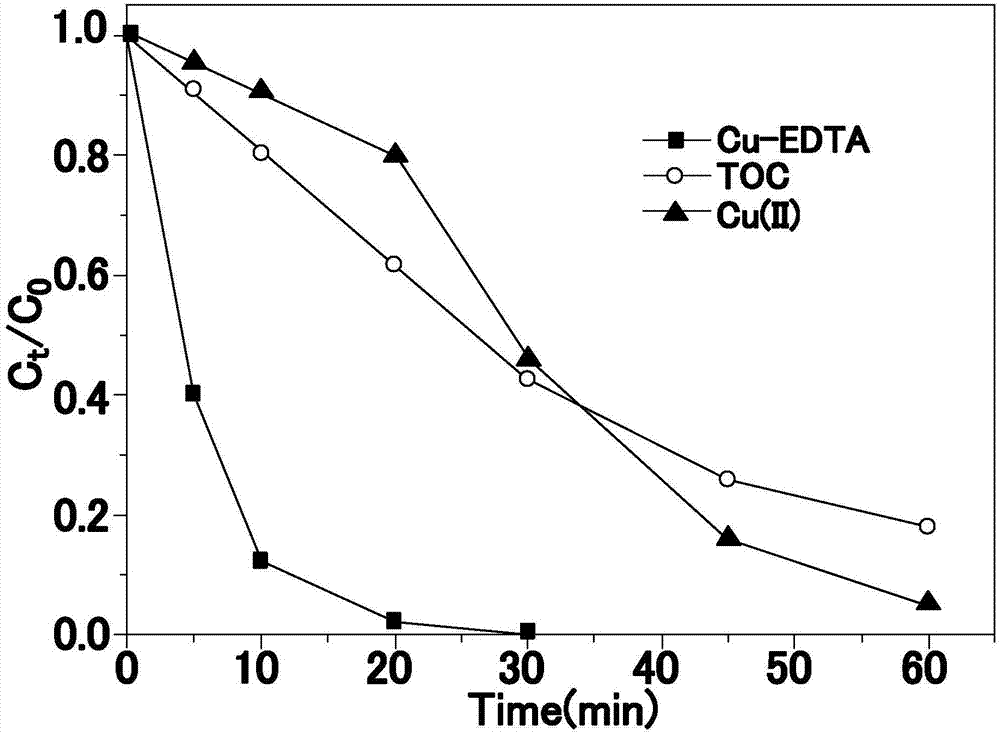

Embodiment 1

[0019] Prepare Cu-EDTA wastewater with tap water at a concentration of 0.3 mmol / L, a molar ratio of sodium hypochlorite to Cu-EDTA of 60, pH 4.0, and a temperature of 25 0 c. Carry out the reaction for 60 min according to the steps in a method for treating heavy metal complex wastewater based on UV / chlorine advanced oxidation technology of the present invention. In this implementation, CuEDTA was completely degraded within 30 min. After 60 min of reaction, the removal rate of TOC was about 82%, and the removal rate of Cu(II) was about 95%.

Embodiment 2

[0021] Prepare Ni-EDTA wastewater with tap water at a concentration of 0.3 mmol / L, a molar ratio of sodium hypochlorite to Ni-EDTA of 90, pH 3.0, and a temperature of 25 0 c. Carry out the reaction for 60 min according to the steps in a method for treating heavy metal complex wastewater based on UV / chlorine advanced oxidation technology of the present invention. In this embodiment, Ni-EDTA is completely degraded within 20 minutes. After 60 minutes of reaction, the removal rate of TOC is about 86%, and the removal rate of Ni(II) is about 98%.

Embodiment 3

[0023] The concentration of Ni-NTA wastewater was prepared with tap water to be 0.3 mmol / L, the molar ratio of bleaching powder to Ni-NTA was 90, pH 4.0, temperature 25 0 c. Carry out the reaction for 60 min according to the steps in a method for treating heavy metal complex wastewater based on UV / chlorine advanced oxidation technology of the present invention. In this embodiment, Ni-NTA was completely degraded within 30 min, and after 60 min of reaction, the removal rate of TOC was about 80%, and the removal rate of Ni(II) was about 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com