Smart sludge drying method

A sludge drying and sludge technology, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of large land occupation of sludge ponds, air and environmental pollution, air pollution, etc. problem, to achieve good heating effect, improve utilization rate, and abundant solar energy resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

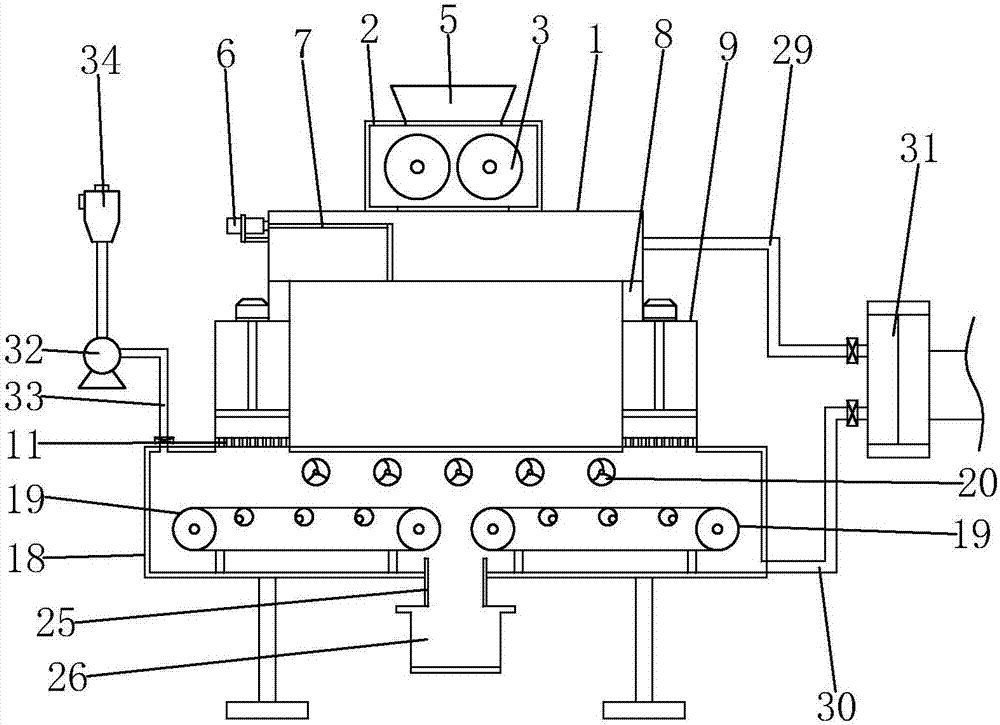

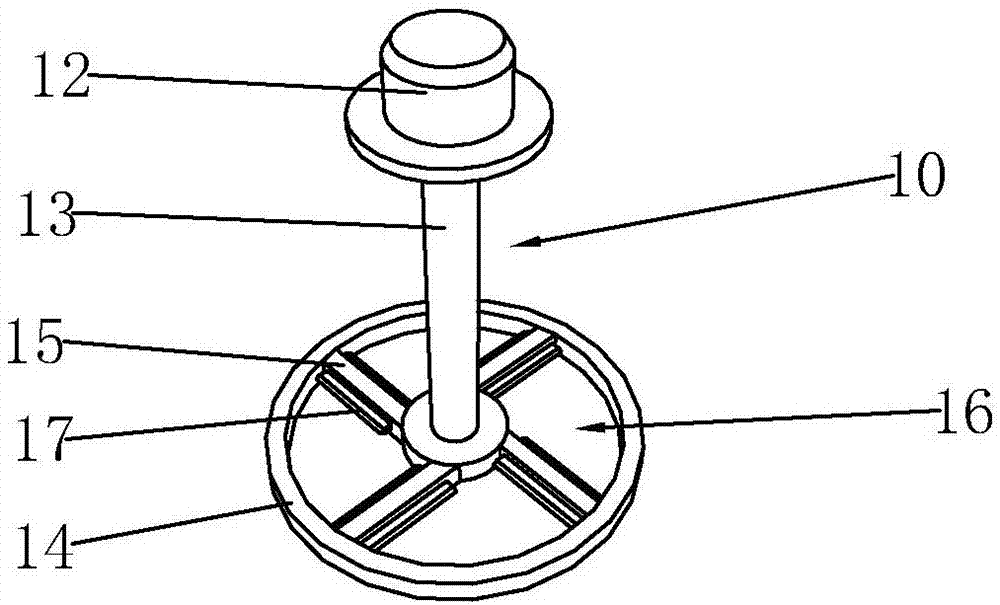

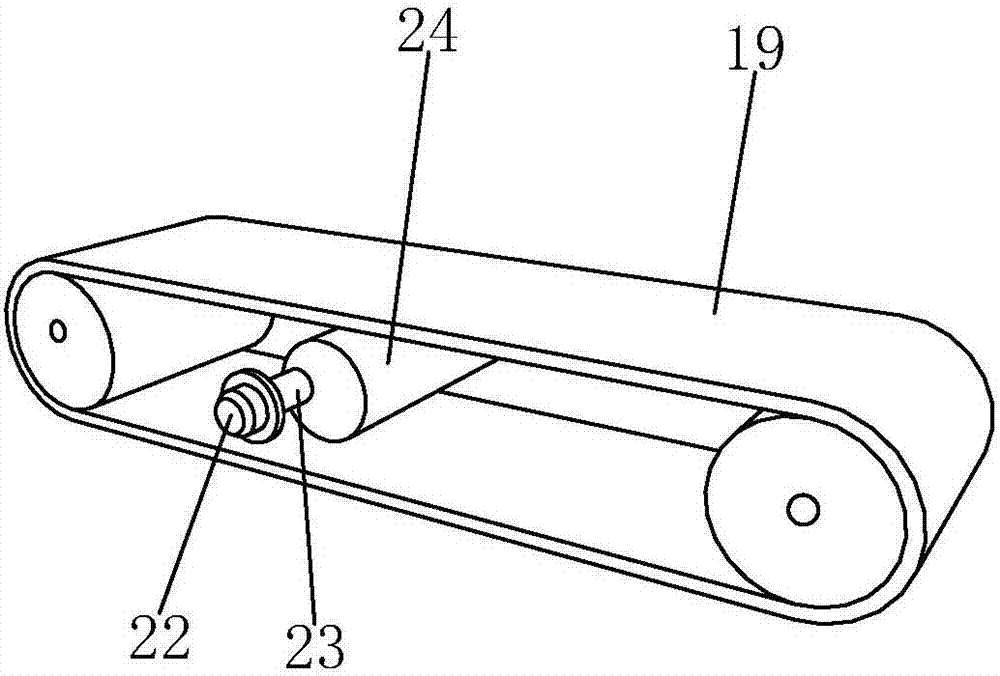

[0029] like Figure 1 to Figure 5 Shown, be a kind of intelligent sludge drying method of the present invention, comprise the steps:

[0030](a) Pretreatment reaction: Add water and flocculant to the reaction tank, turn on the mechanical agitator, stir to form a mixed solution, pump the sludge into the reaction tank with a sludge pump, and continue stirring to make the sludge and flocculant The solution was mixed well, then allowed to stand for 1 to 2 hours, and then filtered. Under the action of the flocculant, the organic molecules in the sludge undergo a rapid gelation reaction to form flocs, the degree of dispersion is reduced, the water holding capacity of the sludge is reduced, and the separation of sludge and water is promoted, thereby increasing the strength and stabilizing the heavy metals in the sludge. The effect can effectively control the secondary pollution after use, and the organic matter is not easy to lose, thereby increasing the organic matter content of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com