Method for preparing fiber-grade polyester chip capable of being applied to processing of textile from waste braided fabric

A technology for polyester chips and waste textiles, which is applied in the field of fiber-grade polyester chips, can solve the problems of inability to realize high-grade recycling of waste textiles, environmental pollution, and difficulty in obtaining them, so as to improve the level of efficient recycling and utilization. Efficient industrial chain circulation and the effect of suppressing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

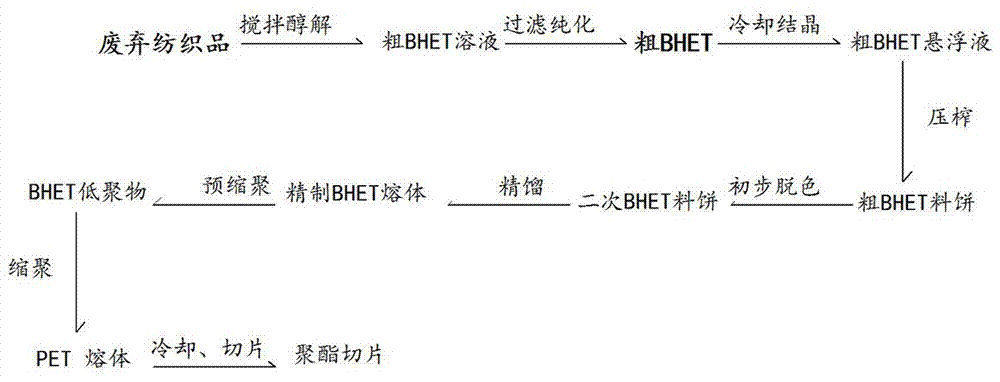

[0045] A method for preparing fiber-grade polyester chips applicable to textile processing from waste textiles, comprising the steps of:

[0046] 1) Pre-pulverize waste textiles into flakes;

[0047] 2) Add the pre-crushed flakes into the alcoholysis device, add triethylene glycol at a mass ratio of 1:2, add the initiator, and keep stirring for 1 hour at 190°C and a pressure of 0.1MPa to obtain crude BHET solution;

[0048] 3) Filtrate and separate the solid waste impurities in the crude BHET solution; obtain a preliminary purified crude BHET solution;

[0049] 4) cooling and crystallizing the obtained preliminary purified crude BHET solution to obtain a crude BHET suspension;

[0050] 5) Obtain the crude BHET cake and separate the triethylene glycol solution containing impurities by pressing the crude BHET suspension;

[0051] 6) Add 25% ethylene glycol by volume to the crude BHET cake, heat to 60°C, add adsorption decolorizer and stir thoroughly at the same time to obtain...

Embodiment 2

[0084] A method for preparing fiber-grade polyester chips applicable to textile processing from waste textiles, comprising the steps of:

[0085] 1) Pre-pulverizing waste textiles into flakes;

[0086] 2) Add the pre-crushed flakes into the alcoholysis device, add triethylene glycol at a mass ratio of 1.25, add the initiator, and keep stirring for 4 hours at 260°C and a pressure of 0.4MPa to obtain crude BHET solution;

[0087] 3) Filtration and separation of solid waste impurities in the crude BHET solution; obtain preliminary purified crude BHET;

[0088] 4) cooling and crystallizing the obtained preliminary purified crude BHET solution to obtain a crude BHET suspension;

[0089] 5) obtaining the crude BHET cake and separating the triethylene glycol solution containing impurities by pressing the crude BHET suspension;

[0090] 6) Add 85% ethylene glycol by volume to the crude BHET cake, heat to 150°C, add adsorption decolorizing agent and stir thoroughly to obtain BHET mi...

Embodiment 3

[0108] A method for preparing fiber-grade polyester chips applicable to textile processing from waste textiles, comprising the steps of:

[0109] 6) Pre-pulverizing waste textiles into flakes;

[0110] 7) Put the pre-crushed flakes into the alcoholysis device, add triethylene glycol at a ratio of 1:1.5 by mass, add the initiator, and keep stirring for 3 hours at 200°C and a pressure of 0.25MPa to obtain crude BHET solution;

[0111] 8) Filtration and separation of solid waste impurities in the crude BHET solution; obtain preliminary purified crude BHET;

[0112] 9) cooling and crystallizing the obtained preliminary purified crude BHET solution to obtain a crude BHET suspension;

[0113] 10) obtaining the crude BHET cake and separating the triethylene glycol solution containing impurities by pressing the crude BHET suspension;

[0114] 6) Add 60% ethylene glycol by volume to the crude BHET cake, heat to 100°C, add adsorption and decolorization agent and stir thoroughly to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com