Numerical control pulse blow-cleaning dust removing system and urban road vacuum sweeper

A dust removal system and pulse technology, applied in the field of numerical control pulse purging dust removal systems and urban road vacuum cleaners, can solve the problems of low dust collection efficiency, low work efficiency, and filter pores cannot be too small, so as to achieve high dust collection efficiency, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

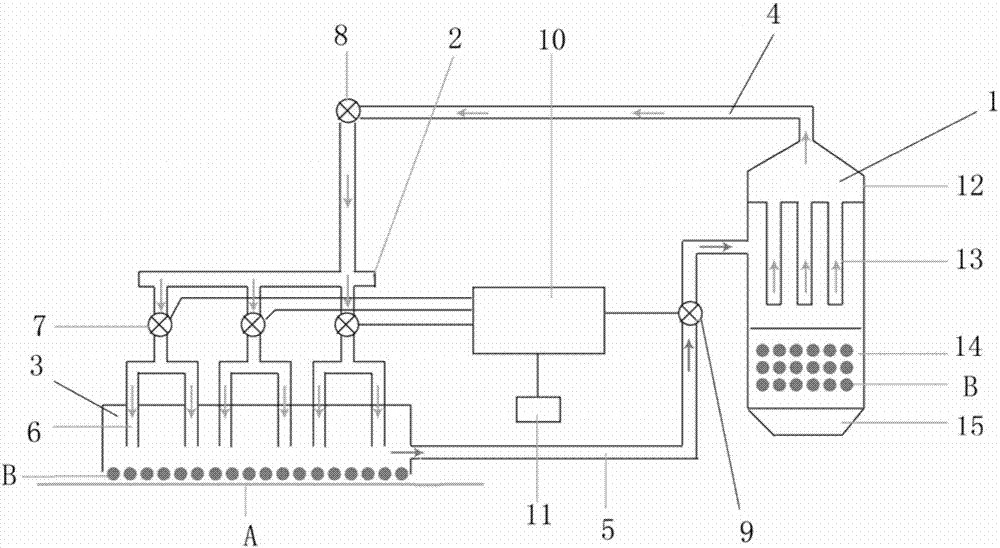

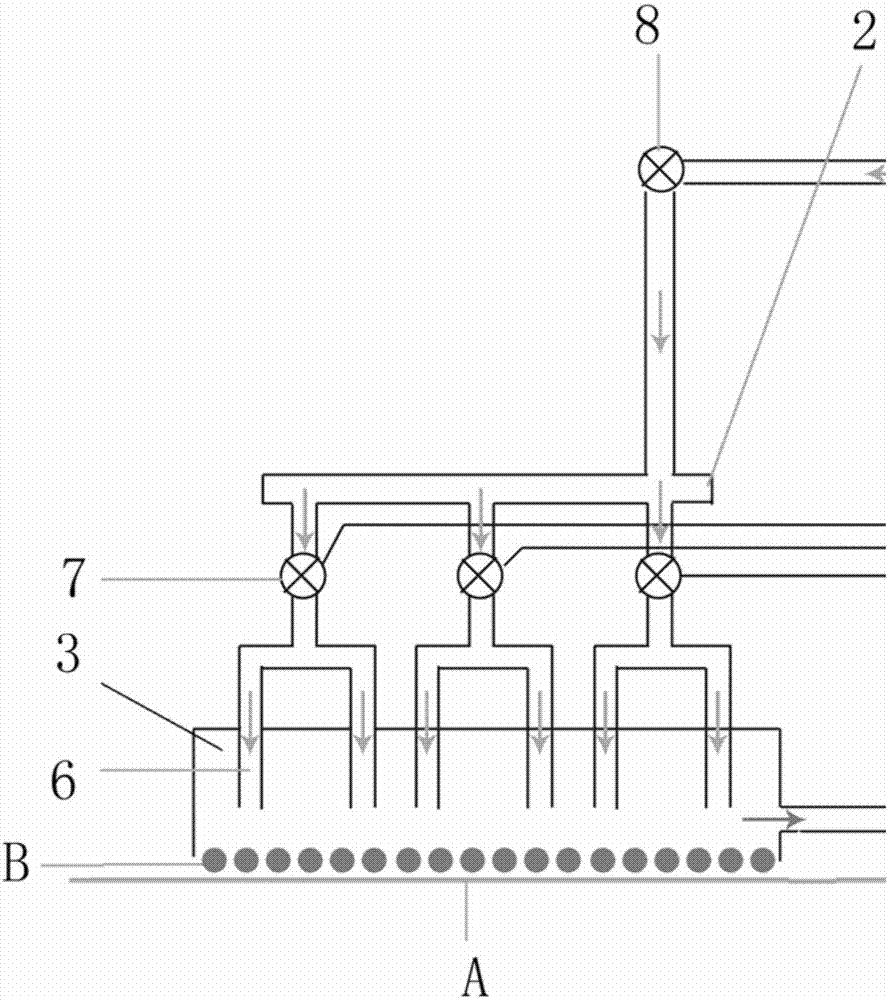

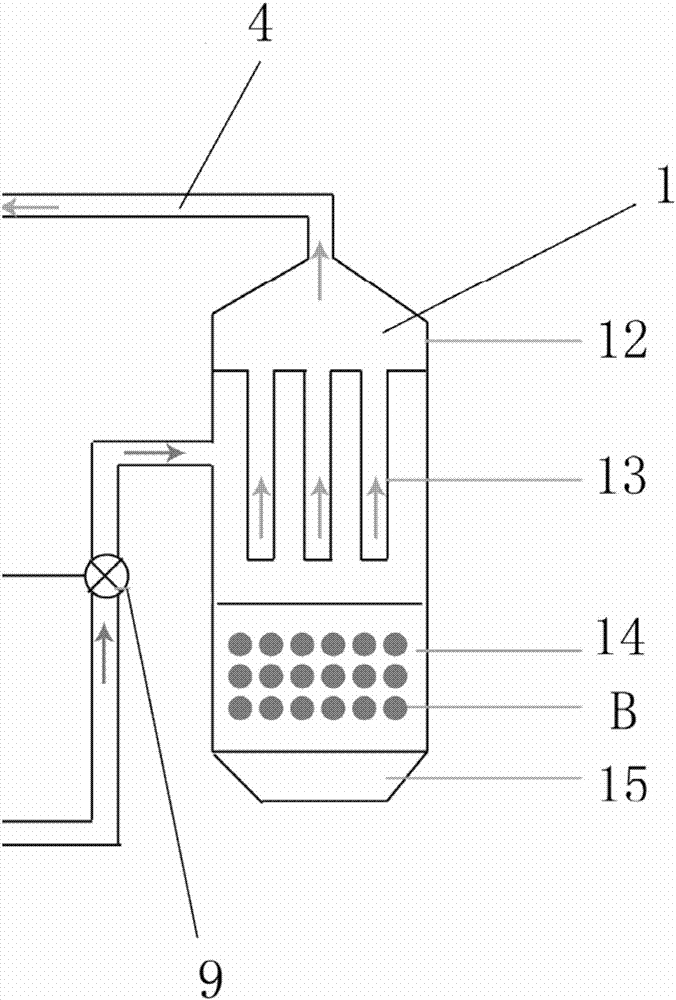

[0052] See figure 1 , figure 2 , image 3 , The first embodiment of the present invention provides a numerically controlled pulse sweeping dust removal system, including a bag filter 1, a sub-cylinder 2, a dust cover 3, an exhaust pipe 4, and a suction pipe 5; figure 2 with image 3 for figure 1 Schematic diagram of the partial enlarged structure;

[0053] The bag filter 1, the sub-cylinder 2, and the dust cover 3 constitute a circulation system through the exhaust duct 4 and the suction duct 5;

[0054] The air outlet of the bag filter 1 is in communication with one end of the exhaust pipe 4, and the other end of the exhaust pipe 4 is in communication with the sub-cylinder 2; the sub-cylinder 2 and the dust cover 3 The air outlet is connected; the air outlet of the dust hood 3 communicates with one end of the suction duct 5, and the other end of the suction duct 5 communicates with the dust inlet of the bag filter 1;

[0055] The sub-cylinder 2 includes a cylinder block and a pl...

Embodiment 2

[0081] Correspondingly, the present invention also provides an urban road dust collection vehicle, including a vehicle body and a numerically controlled pulse sweeping dust removal system provided on the vehicle body (ie, the numerically controlled pulse sweeping dust removal system involved in the first embodiment of the present invention) ).

[0082] The numerical control pulse sweeping and dust removal system provided in the second embodiment of the present invention can utilize the function of the numerical control pulse sweeping and dust removal system and apply it to a road dust collection vehicle to form an urban road dust collection vehicle that realizes brand-new functions. The above-mentioned urban road dust-collecting vehicle has obvious dust-absorbing effect, low cost, low energy consumption, energy saving and environmental protection. The working speed of the above-mentioned urban road vacuum cleaner is greatly increased, and it is suitable for rapid operation on exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com