Texturing cleaning machine and water circulation method

A washing machine and texturing technology, which is applied in the directions of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of high processing cost, time-consuming, complicated steps, etc., to reduce pollution and save energy. Water resources, the effect of reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

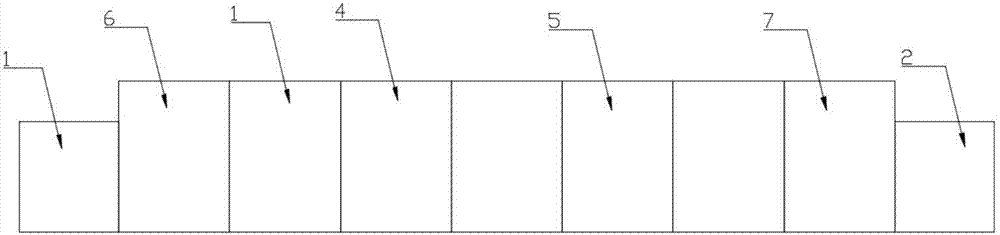

[0027] A kind of cashmere cleaning machine of the present invention comprises feeding device 1, unloading device 2, cashmere tank 3, alkali tank 4, acid tank 5, water tank 6 and drying tank 7, wherein, cashmere tank 3 and alkali A water tank 6 is set between the tanks 4, a water tank 6 is set between the alkali tank 4 and the acid tank 5, a water tank 6 is set between the acid tank 5 and the drying tank 7, and a feeding device 1 is arranged at the front end of the cashmere tank 3, and the drying The rear end of the tank 7 is provided with a blanking device 2;

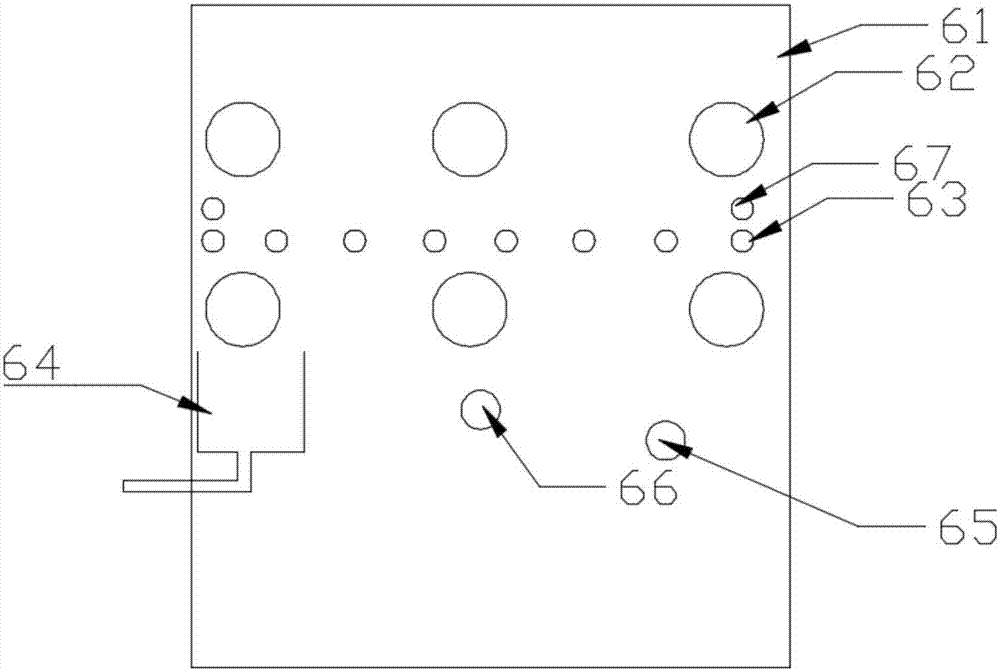

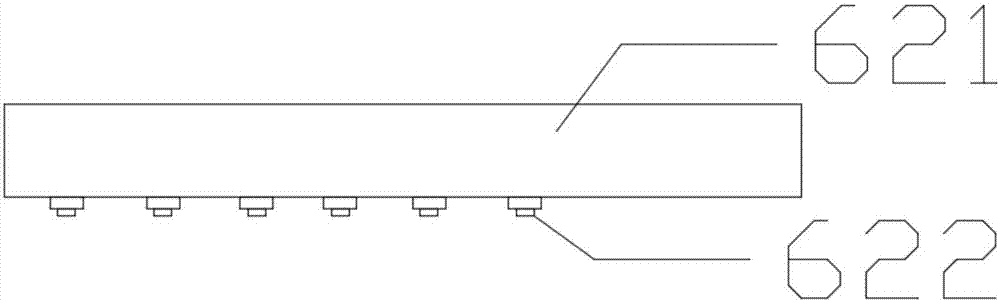

[0028] The water tank 6 includes a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com