Red bean jelly and processing method thereof

A production method, red bean technology, applied in the field of food processing, can solve the problems of affecting the appearance of the product, unstable pigment, easily broken candied red beans, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

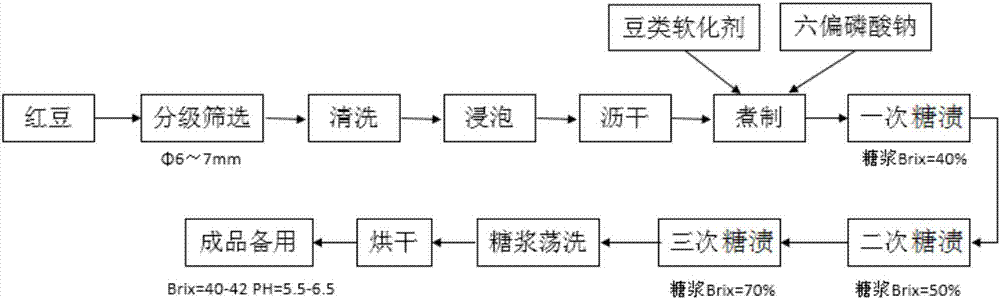

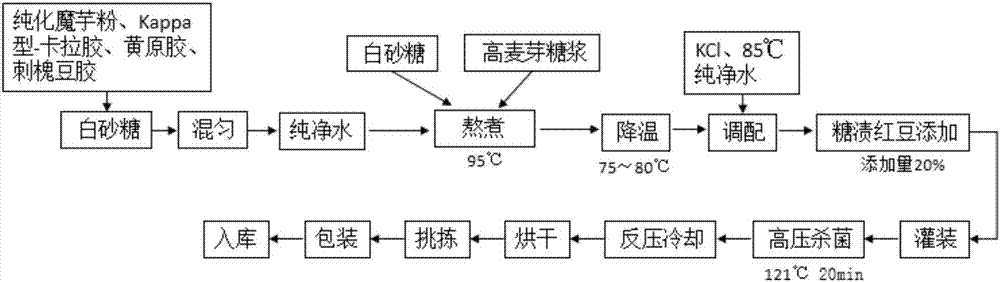

[0117] Preparation of candied red beans:

[0118] Formula dosage: 33.4wt% of red bean, 0.5wt% of bean softener, 0.5wt% of sodium hexametaphosphate, 30wt% of high maltose syrup, 10wt% of white sugar and the rest of purified water

[0119] Raw material selection: Grading and screening out the deer seeds with a diameter of 6-7mm, the granules are complete and the color is consistent, and the worm-eaten and mildewed granules are manually removed;

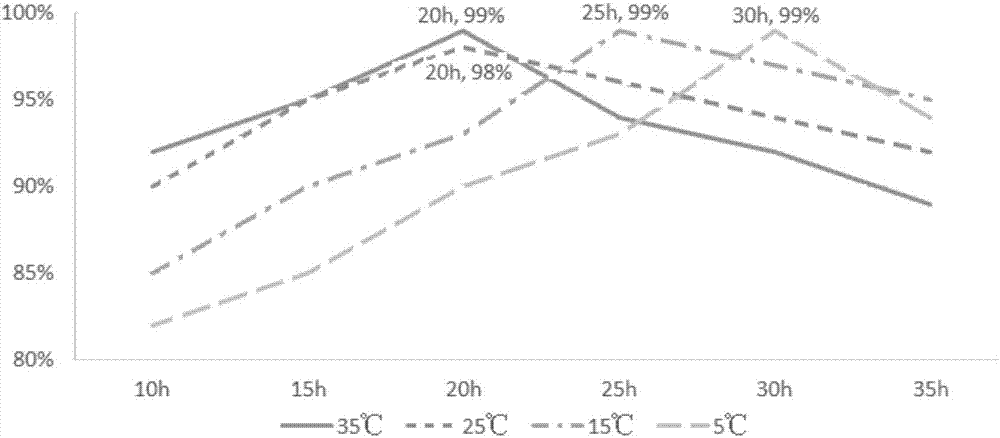

[0120]Red bean soaking: The graded and screened red bean is poured into a stainless steel tank and soaked in 3 times its weight of water. The soaking time is 20 hours (summer, about 35°C). After soaking, the red bean is screened to remove hard beans.

[0121] Drain: After soaking the red beans, use a sieve to filter out the soaking water;

[0122] Rinse: Rinse again with water to remove the floating color on the surface of the red bean;

[0123] Cooking: Boiled beans are cooked under normal pressure. Put pure water 3 times the weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com