Plastic-ampule sterile preparation process and system based on sterile preparation and three-in-one function of blowing, filling and sealing

A blow-fill-seal, three-in-one technology, applied in the field of plastic ampoule aseptic preparation process, plastic ampoule aseptic preparation technology and system field, can solve the problems of lack of sterilization function and the preparation system is not paid much attention, to reduce sterilization. Bacteria energy consumption, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

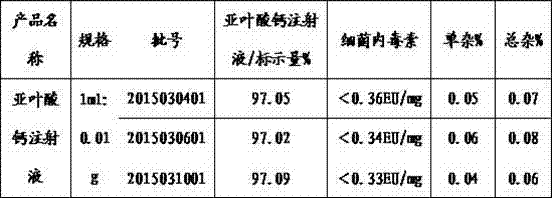

Embodiment 1

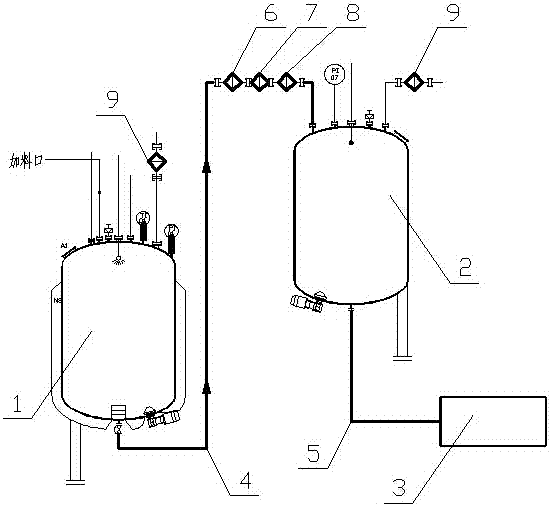

[0052] The three-in-one plastic ampoule aseptic preparation process integrating aseptic preparation and blow-fill-seal is characterized in that it includes the following steps:

[0053] 1) Preparation before preparation, including:

[0054] A. Confirm that the supply pressure of compressed air is 4bar, the supply pressure of pure steam is above 3bar, and the water for injection has been supplied.

[0055] B. Online cleaning and sterilization of mixing tanks and sterile storage tanks,

[0056] C. Close the bottom valve of the mixing tank, collect the process water for injection in the mixing tank, turn on the magnetic stirrer, set the speed at 45Hz,

[0057] D. Run the laminar flow hood for 30 minutes before weighing; by extracting the air in the room, filtering it, and then removing it from the top laminar flow hood of the negative pressure weighing chamber, and continuously purifying the air in the negative pressure weighing chamber, it takes 20 minutes to Guarantee the sel...

Embodiment 2

[0083] The three-in-one plastic ampoule aseptic preparation process integrating aseptic preparation and blow-fill-seal is characterized in that it includes the following steps:

[0084] 1) Preparation before preparation, including:

[0085] A. Confirm that the supply pressure of compressed air is 2bar, the supply pressure of pure steam is 2bar, and the water for injection has been supplied.

[0086] B. Online cleaning and sterilization of mixing tanks and sterile storage tanks,

[0087] C. Close the bottom valve of the mixing tank, collect the process water for injection in the mixing tank, turn on the magnetic stirrer, set the speed at 35Hz,

[0088] D. Run the laminar flow hood for 20 minutes before weighing;

[0089] 2) Weighing, specifically including:

[0090] A. Select a scale with a weighing range close to the weighing value of raw and auxiliary materials in the negative pressure weighing chamber.

[0091] B. Adjust the base of the scale so that the air bubbles are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com