Flow electroporation device

A technology of flow electroporation and temperature control device, which is applied in the field of electroporation, which can solve the problems of electrode electric field intensity distribution change, electroporation result change, time-consuming and other problems, achieve less cell damage, improve electroporation efficiency, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

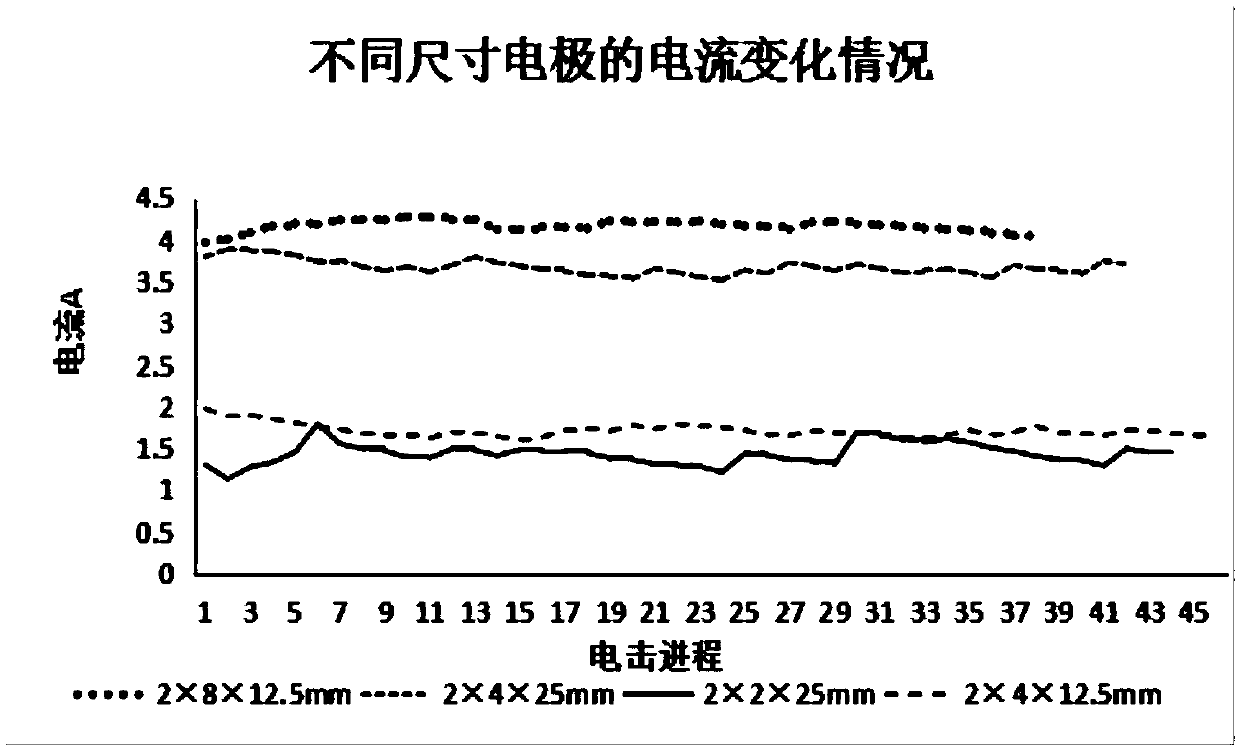

[0097] Electrode shape and size selection

[0098] The flow electroporation device of the present invention adopts planar electrodes, and the size of the planar electrodes determines the speed of processing cells per unit time, and the length, width and spacing of electroporation chambers have different effects. When the flow rate is constant, the length of the planar electrode affects the time of solution flow inside the electrode. Increasing the electrode length will increase the contact time of the bubbles with the electrode surface when they flow through the electrode area, increasing the probability of bubble retention. The width of the planar electrode affects the flow rate of the solution inside the electrode. The flow rate in the middle area of the fluid is fast, and the flow rate in the edge area is slow. The larger the electrode width, the more obvious the deviation. The distance between planar electrodes affects the strength of the electric field. According to the...

Embodiment 2

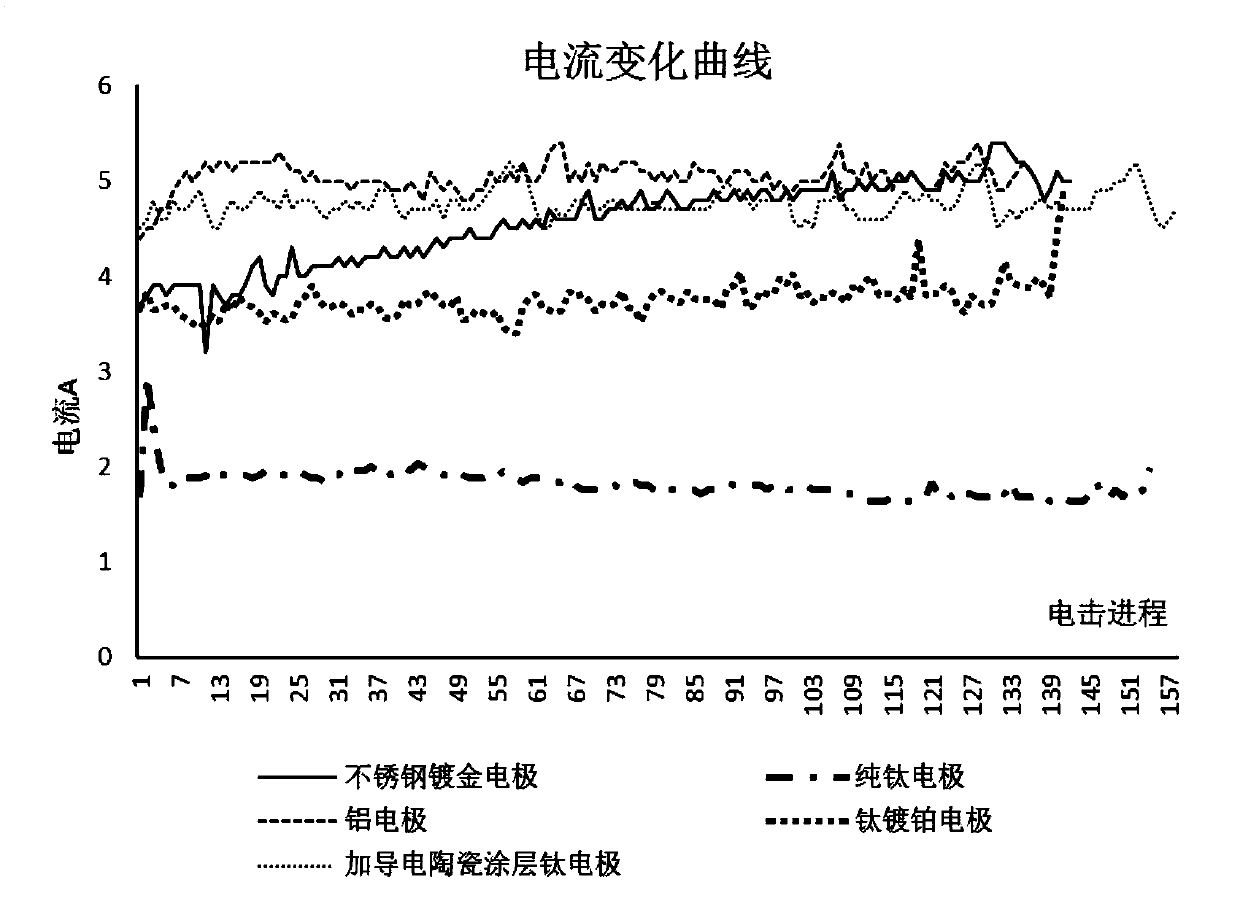

[0102] Choice of planar electrode material

[0103] In the flow electroporation device of the present invention, the research and development of the planar electrode material is the core content. The surface of the planar electrode should be smooth and flat, and the contact with the support should be smooth without step difference and form a sealed chamber to minimize the possibility of air bubble retention. Through the selection of electrode materials, optimization of electrode structure and control of electric field strength, the adverse effects of electrochemical reaction products on the electrotransfection effect during the electric shock process can be reduced.

[0104] Design of the experimental scheme: the types of planar electrode materials that can be selected in this embodiment are aluminum, 304 stainless steel, pure gold, gold-plated stainless steel, pure titanium, titanium with a conductive ceramic coating, pure platinum, platinum-plated titanium, and pure iridium; ...

Embodiment 3

[0134] Selection of different ways for fluids to enter and exit the electroporation chamber

[0135] Experimental scheme design: The angle between the horizontal angle when the fluid enters the electroporation chamber and the horizontal angle when it flows in the electroporation chamber can be between 0° and 90°. When the angle is 0°, the fluid is positively entering and positively exiting. , when the angle is 90°, the fluid is side-in and side-out. The main way for the fluid to enter and exit is that the liquid inlet and outlet of the bracket extend in a straight line, so that the silicone tube at the proximal end of the electrode is connected in parallel to the electrode. The main way of side-in and side-out of the fluid is that the liquid inlet and outlet of the bracket form a 90° angle with the flat electrode, so that the silicone tube at the proximal end of the electrode is vertically connected to the electrode.

[0136] Choose titanium-platinum-plated planar electrode, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com