Sand blasting head position adjusting device based on position detection and sand blasting device

A technology of detection device and sandblasting device is applied in used abrasive processing devices, explosion generating devices, spray guns and other directions, which can solve the problems of environmental pollution, affecting the safety of on-site operators and the consumption of steel grit, and achieve good safety, Sandblasting quality with high reliability and high reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

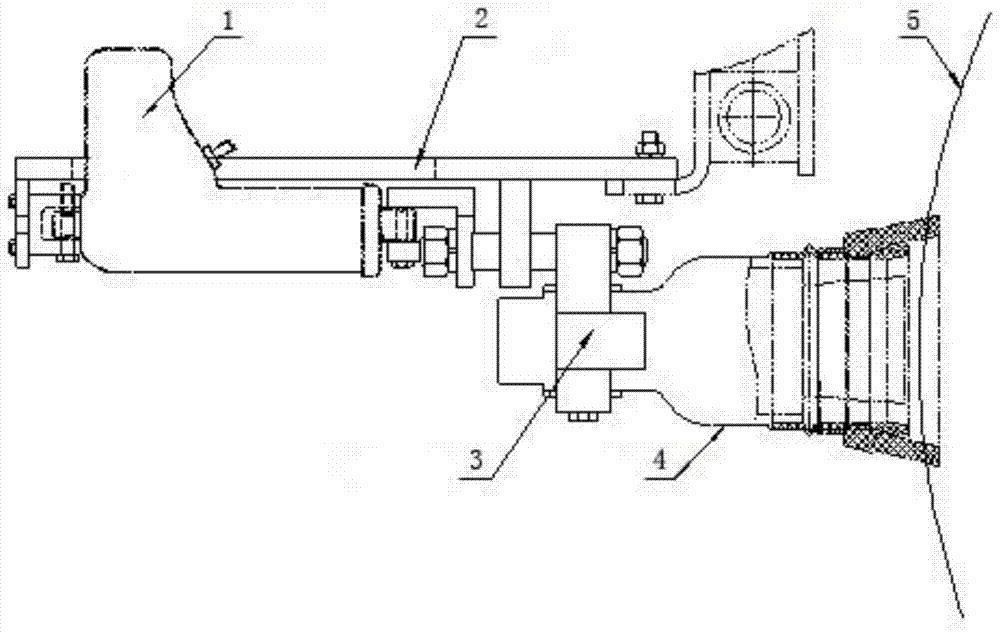

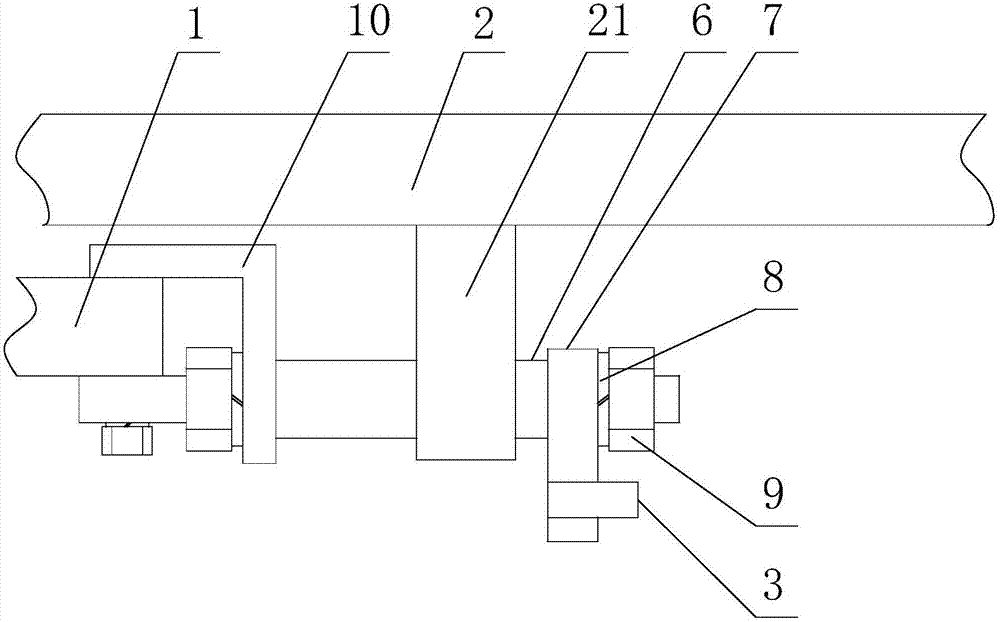

[0032] Such as figure 1 with figure 2 As shown, a position adjustment device for a sandblasting head based on position detection includes a mounting plate 7 for fixing the sandblasting head 4, and also includes a position detection device 3 and a driving mechanism 1. The mounting plate 7 is mounted on the driving mechanism 1 Above, the driving mechanism 1 is used to adjust the position of the mounting plate 7;

[0033] The position detection device 3 is used to detect the relative position of the sandblasting head 4 or the mounting plate 7 and the workpiece 5, and the signal output end of the position detection device 3 is connected to the control unit of the driving mechanism 1, and the output signal of the position detection device 3 is used as The control signal for the operation of the drive mechanism 1.

[0034] The above adjustment device has a simple structure. The drive mechanism 1 is used to install on the frame 2 matched with the sandblasting device. At the same time, t...

Embodiment 2

[0038] Such as figure 1 with figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: As an integrated solution, the position detection device 3 is fixed on the mounting plate 7. As a person skilled in the art, if the position detecting device 3 is to realize its function, it can move with the sandblasting head 4, so the position detecting device 3 can also be installed on the sandblasting head 4.

[0039] As a specific solution that is easy to implement, the position detection device 3 is a distance measuring sensor, and the driving mechanism 1 is a linear motor that outputs linear motion. In this solution, the distance measuring sensor can be a commonly used sensor based on laser, infrared, ultrasonic and other measurement methods. The specific selection of the driving mechanism 1 is to make the device as small in size and light in weight as possible. , To better adapt to field work. As a person skilled in the art, the above driving mechanism 1 can...

Embodiment 3

[0041] This embodiment further limits the case on the basis of the technical solution provided in embodiment 1, such as figure 1 with figure 2 As shown, this embodiment provides a sandblasting device based on position detection, which includes a sandblasting head 4 and a frame 2, and also includes any one of the sandblasting head 4 position adjustment devices provided in any of the above embodiments. The mechanism 1 is fixed on the frame 2, and the sandblasting head 4 is fixed on the mounting plate 7;

[0042] The movement direction of the mounting plate 7 under the action of the driving mechanism 1 is parallel to the direction of the sandblasting port of the sandblasting head 4. In the above sandblasting device, the distance between the sandblasting head 4 and the pipe surface can be effectively controlled, so as to ensure the safety of on-site operators, reduce the speed of steel grit consumption, and be environmentally friendly; at the same time, because the nozzles of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com