Compound multifunctional shot blasting machine

A multi-functional, shot blasting machine technology, applied in abrasive jet machine tools, used abrasive treatment devices, filter screens, etc., can solve the problems of single function, low work efficiency, and low resource utilization, and achieve resource utilization. High, high work efficiency, and the effect of improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

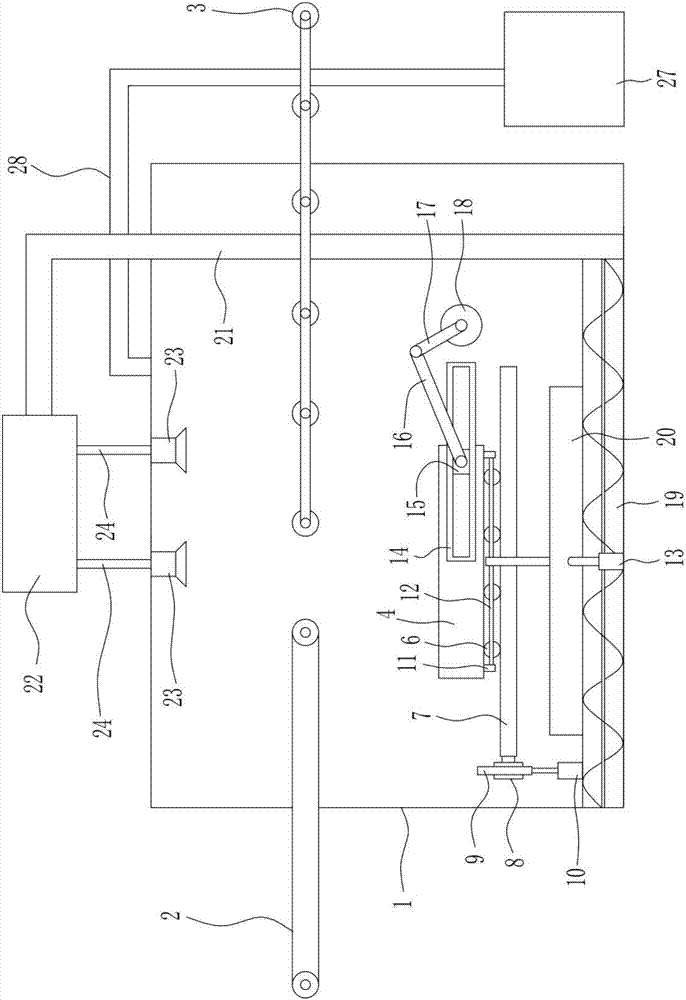

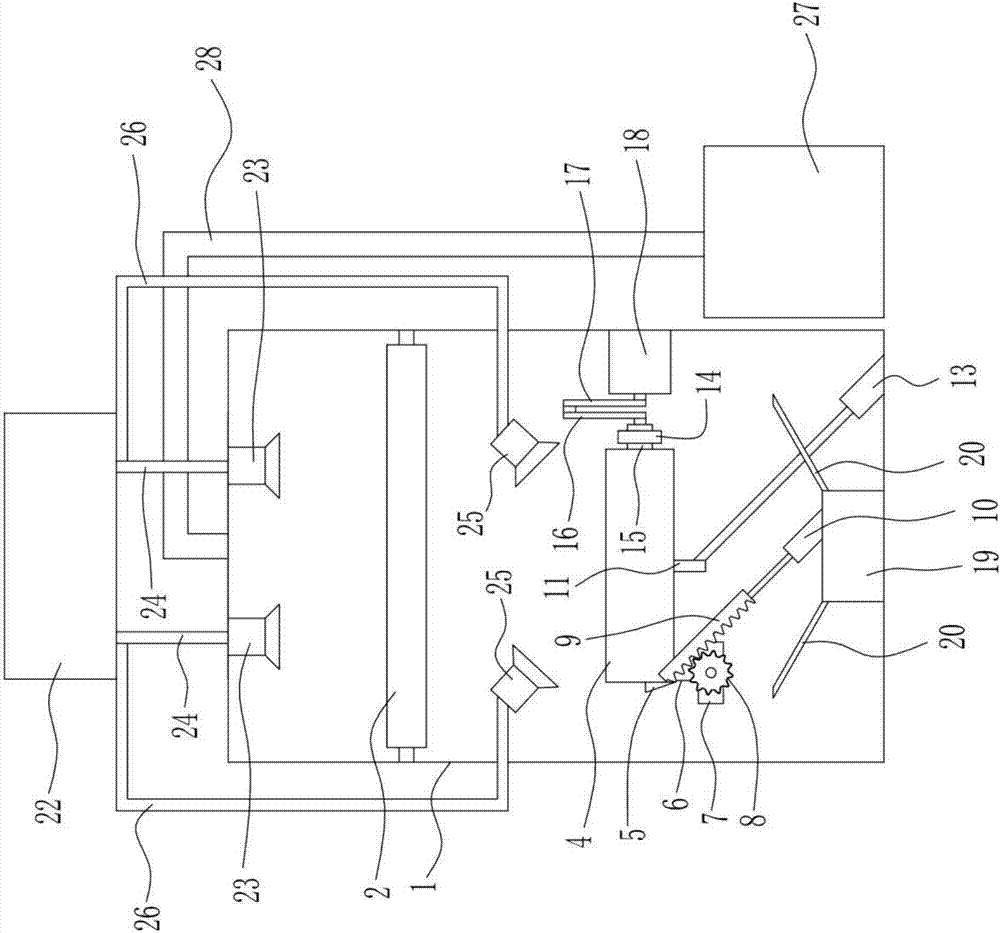

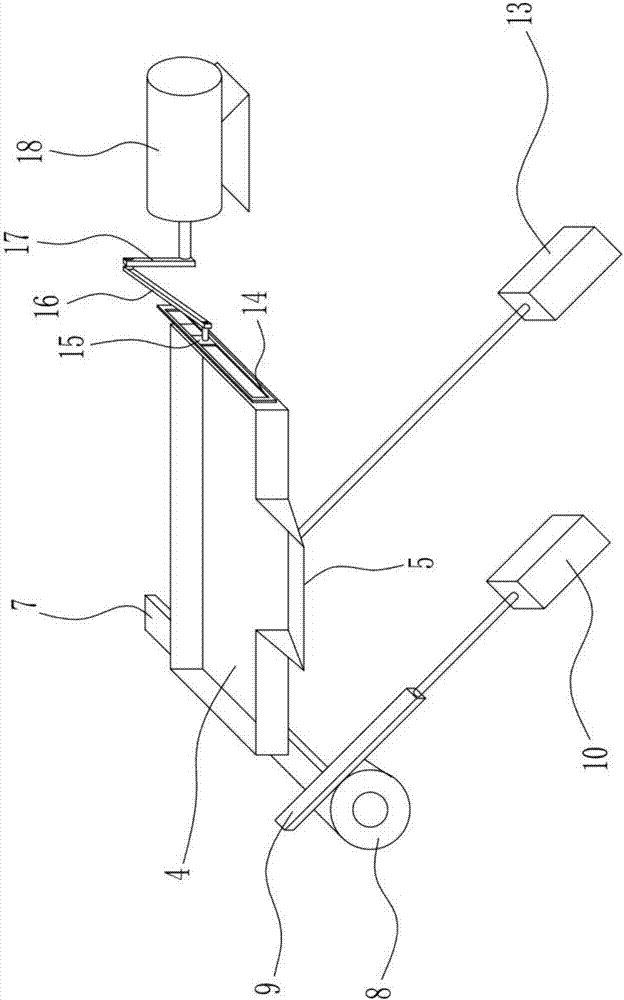

[0036] A compound multifunctional shot blasting machine, such as Figure 1-Figure 6 As shown, it includes frame 1, conveying device 2, roller table 3, screw conveyor 19, baffle plate 20, bucket elevator 21, separator 22, shot blaster I23, feeding pipe I24, shot blaster II25 , feeding pipe II 26, dust remover 27 and dust suction cylinder 28, a transmission device 2 is installed on the frame 1, a roller table 3 is installed on the right side of the transmission device 2, and a screw conveyor 19 is installed below the roller table 3, and the screw conveyor Baffles 20 are welded symmetrically on both sides of 19, a bucket elevator 21 is connected to the right end of the screw conveyor 19, and a separator 22 is connected to the other end of the bucket elevator 21, and the separator 22 is fixedly installed on the upper side of the frame 1 to separate There are eight shot blasting devices I23 fixedly installed under the device 22, and a feeding pipe I24 is connected between the shot ...

Embodiment 2

[0038] A compound multifunctional shot blasting machine, such as Figure 1-Figure 8 As shown, it includes frame 1, conveying device 2, roller table 3, screw conveyor 19, baffle plate 20, bucket elevator 21, separator 22, shot blaster I23, feeding pipe I24, shot blaster II25 , feeding pipe II 26, dust remover 27 and dust suction cylinder 28, a transmission device 2 is installed on the frame 1, a roller table 3 is installed on the right side of the transmission device 2, and a screw conveyor 19 is installed below the roller table 3, and the screw conveyor Baffles 20 are welded symmetrically on both sides of 19, a bucket elevator 21 is connected to the right end of the screw conveyor 19, and a separator 22 is connected to the other end of the bucket elevator 21, and the separator 22 is fixedly installed on the upper side of the frame 1 to separate There are eight shot blasting devices I23 fixedly installed under the device 22, and a feeding pipe I24 is connected between the shot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com