Rolling centrifugal driving device

A driving device, centrifugal technology, applied in the direction of engine components, machines/engines, hydroelectric power generation, etc., can solve the problems of short service life, reduced loading, and various equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

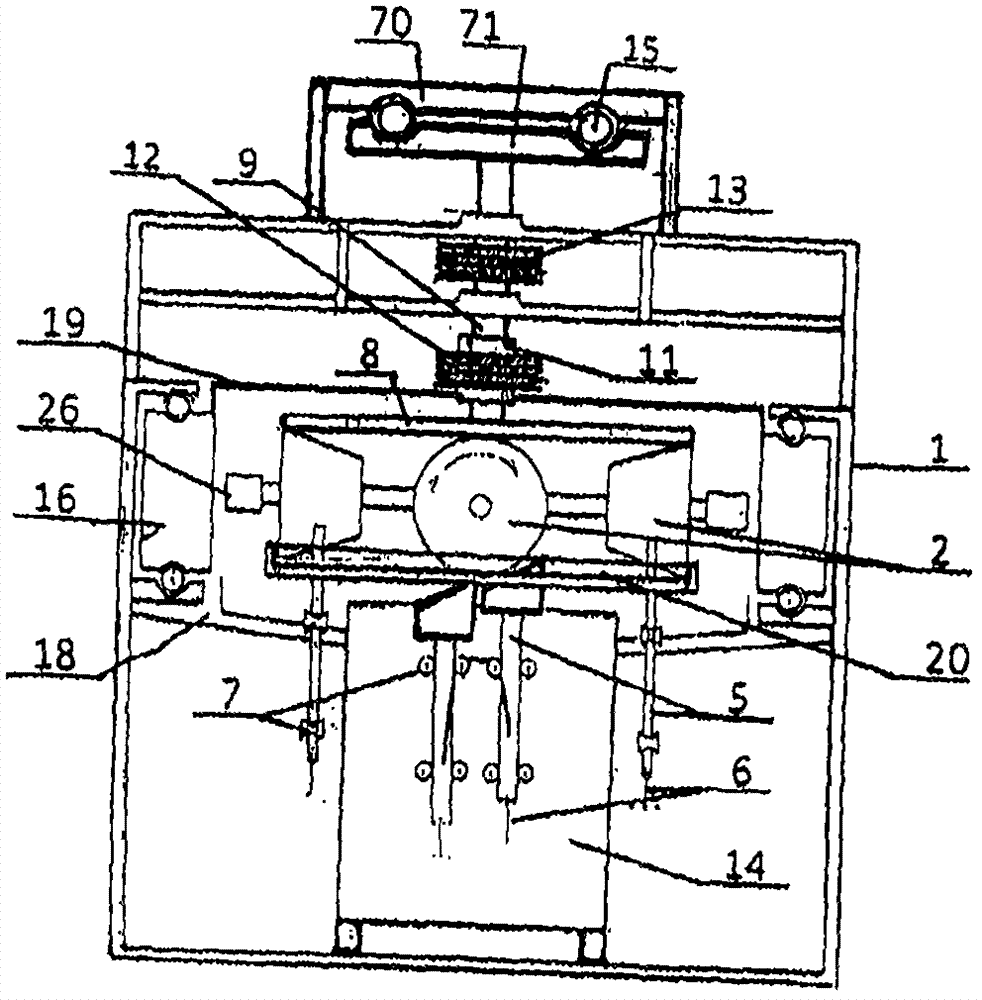

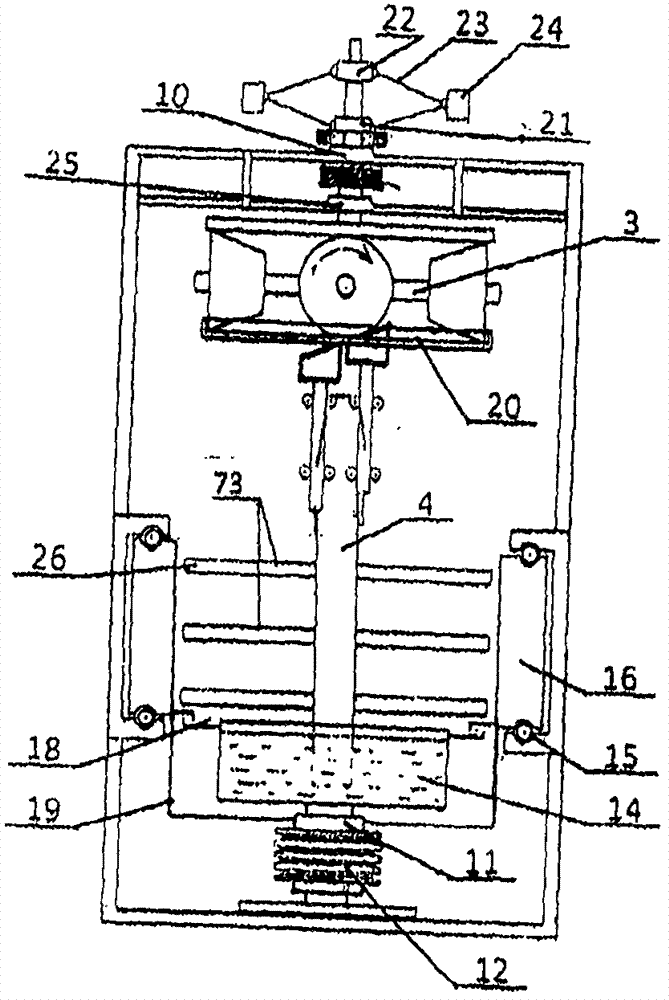

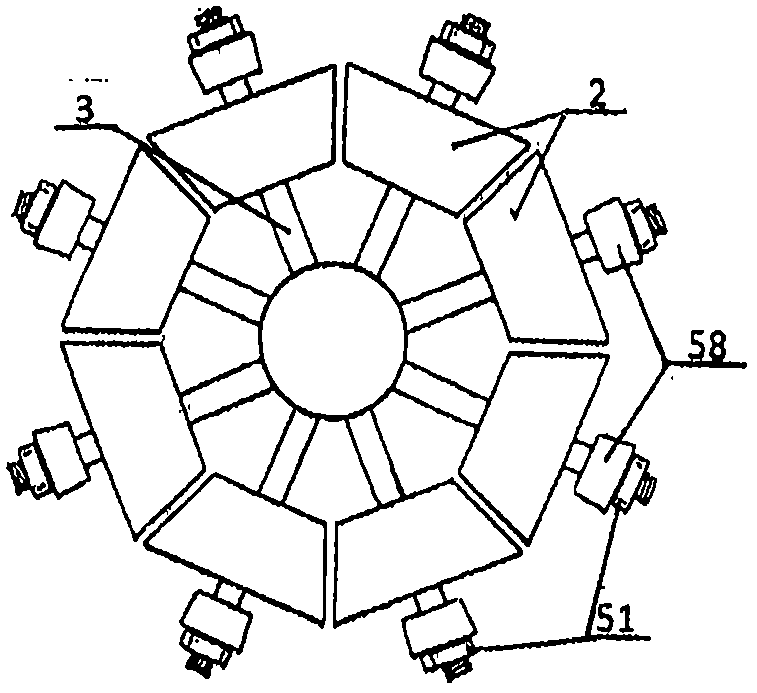

[0047] Further clarification will be made below in conjunction with the accompanying drawings.

[0048] refer to Figure 1 to Figure 3, a plurality of rollers 2 (only three in the left and right are shown in the figure) arranged in an annular ring are placed on the annular track 20, each roller is connected by a central drive shaft 3 and each roller is connected as a whole, the pressure plate 8 The outer edge circumference of the lower plane is pressed against the top dead center of each roller 2, and the vertical shaft 9 is installed in the middle of the upper plane of the pressure plate 8. The vertical shaft is supported and positioned by the upper and lower bearing seats 10 and 25 respectively containing bearings. The top of the upper end of 9 is equipped with a moving plate 71 that can run with the vertical shaft, and the upper section of the vertical shaft is equipped with a transmission wheel 13 for receiving the transmission of the power (not shown in the figure) machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com