Light-emitting device, pixel defining layer and manufacturing method thereof

A technology of pixel definition layer and definition layer, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of inability to meet, affect the display effect, and the transparent pixel definition layer cannot block lateral outgoing, so as to achieve blocking side effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

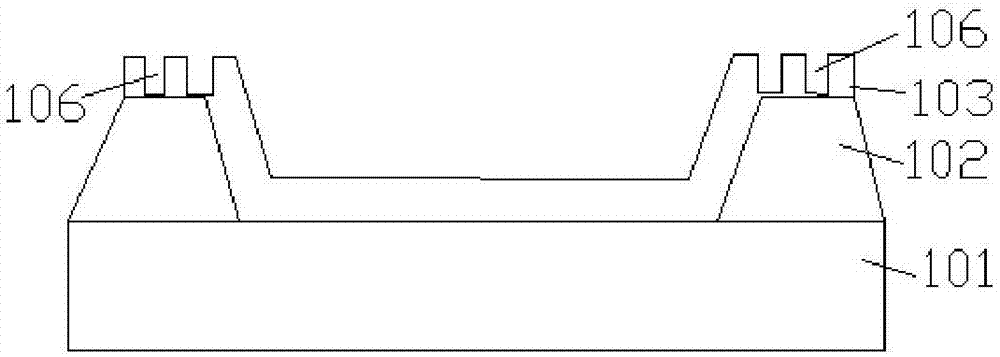

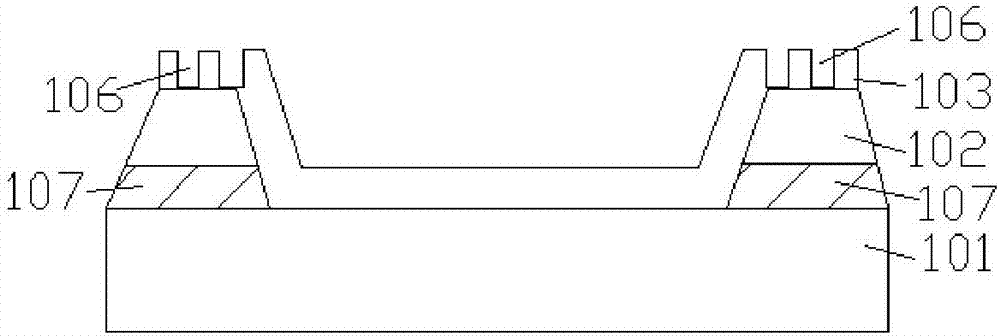

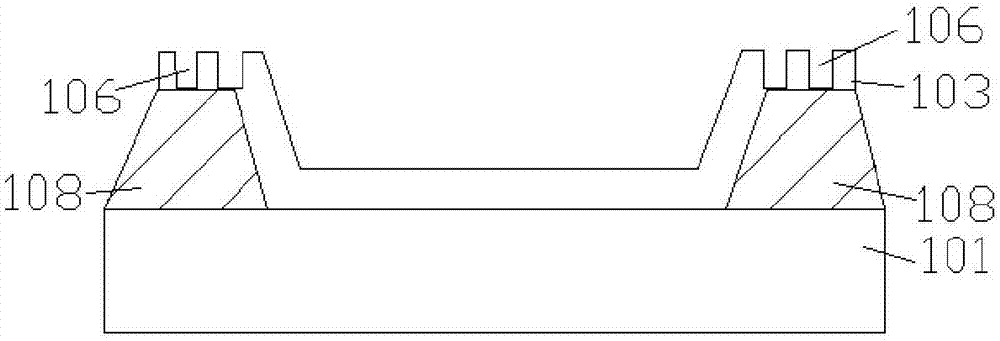

[0043] Please refer to figure 1 , the pixel defining layer in Embodiment 1 of the present invention includes a dam body 102 disposed on a substrate 101 as the first defining layer, and the dam body 102 in this embodiment adopts a common defining layer material, which does not require lyophilicity characteristics; then the metal layer 103 is set above the base 101 and the dam body 102, as the second delimiting layer, specifically a layer of metal film that is coherently arranged on the base 101 and the dam body 102 side walls and the top, and is positioned at the top of the dam body 102 The surface of the metal layer 103 has a nano-microstructure 106, which meets the hydrophobicity requirements of the upper part of the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com