Production process of memory alloy rope for vascular stent

A production process and memory alloy technology, which is applied in the production process field of memory alloy ropes for vascular stents, can solve problems such as broken wires, influence of alloy rope twisting, and heavy single wire weight, so as to ensure twisting quality and reduce single wires The effect of beating and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The features and advantages of the present invention are described in detail below in conjunction with the accompanying drawings.

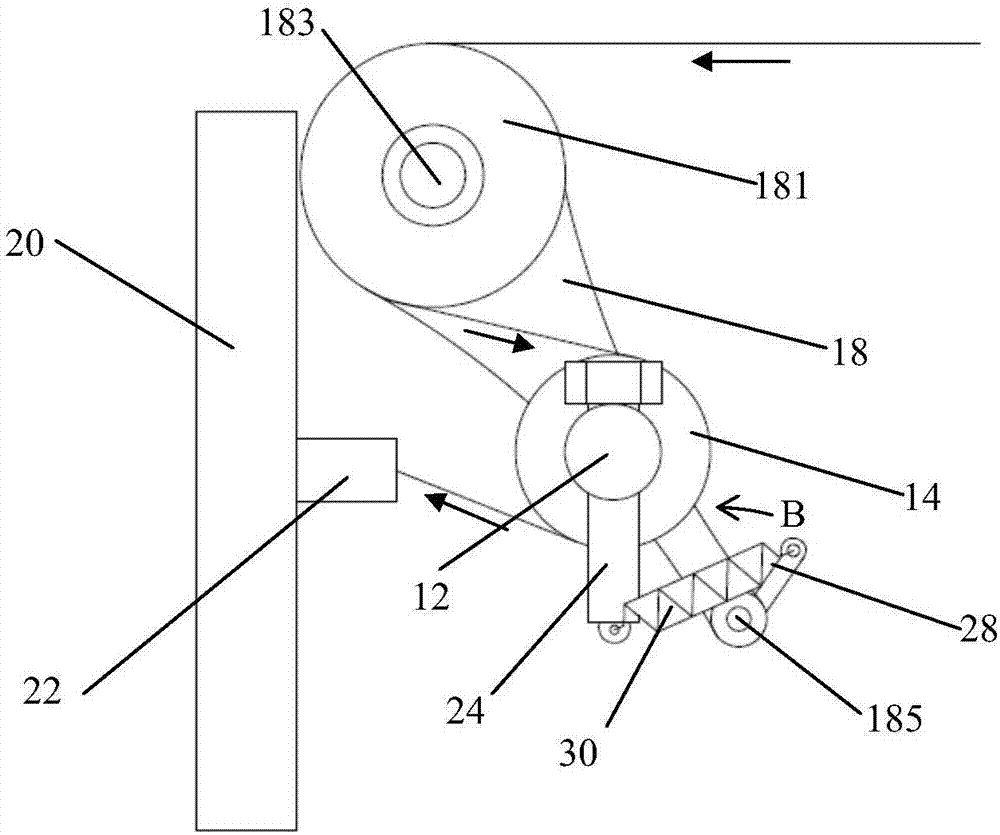

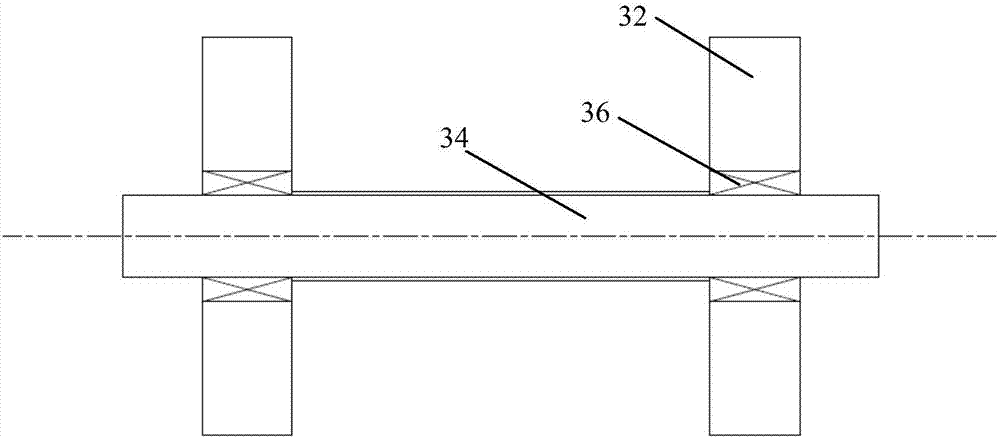

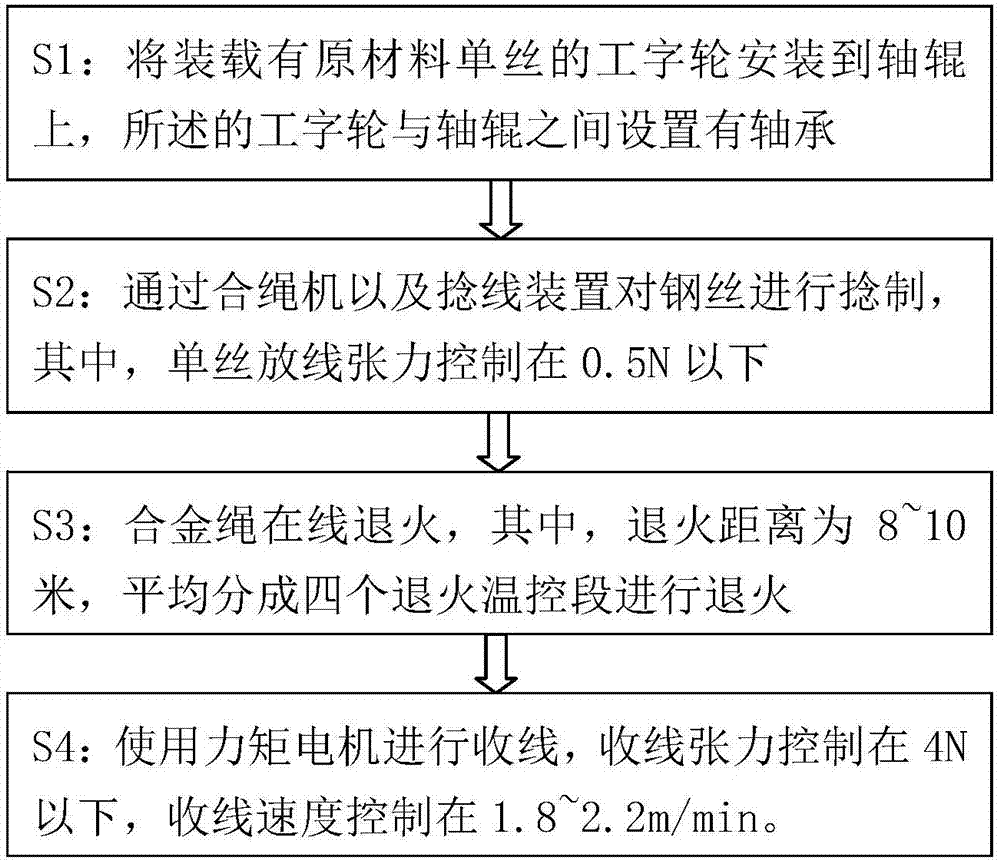

[0020] Since the production process of the present invention is aimed at the twisting production of alloy ropes with very small single wire diameters and rope diameters, in order to avoid broken wires when the machine suddenly stops and restarts during the twisting process, it is necessary to use the current steel wire rope closing machine A constant tension control device is added to the middle. refer to figure 1 The structural schematic diagram of the cradle device of the rope closing machine in the shown steel wire rope production process of the present invention, described cradle device comprises fork 18, and its lower end is fixed with the support of cradle device by rotating shaft 185, is installed by shaft 183 on the fork 18 The first steel wire guide wheel 181 is arranged; The roller shaft 12 fixed with the support of the cradle de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com