Multilayer polyvinyl acetal film and laminated glass including same

A polyvinyl acetal film and polyvinyl acetal resin technology, applied in the field of multilayer polyvinyl acetal film and laminated glass including the same, can solve problems such as insufficient sound insulation performance, achieve excellent sound insulation, excellent Effects of performance, excellent penetration and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

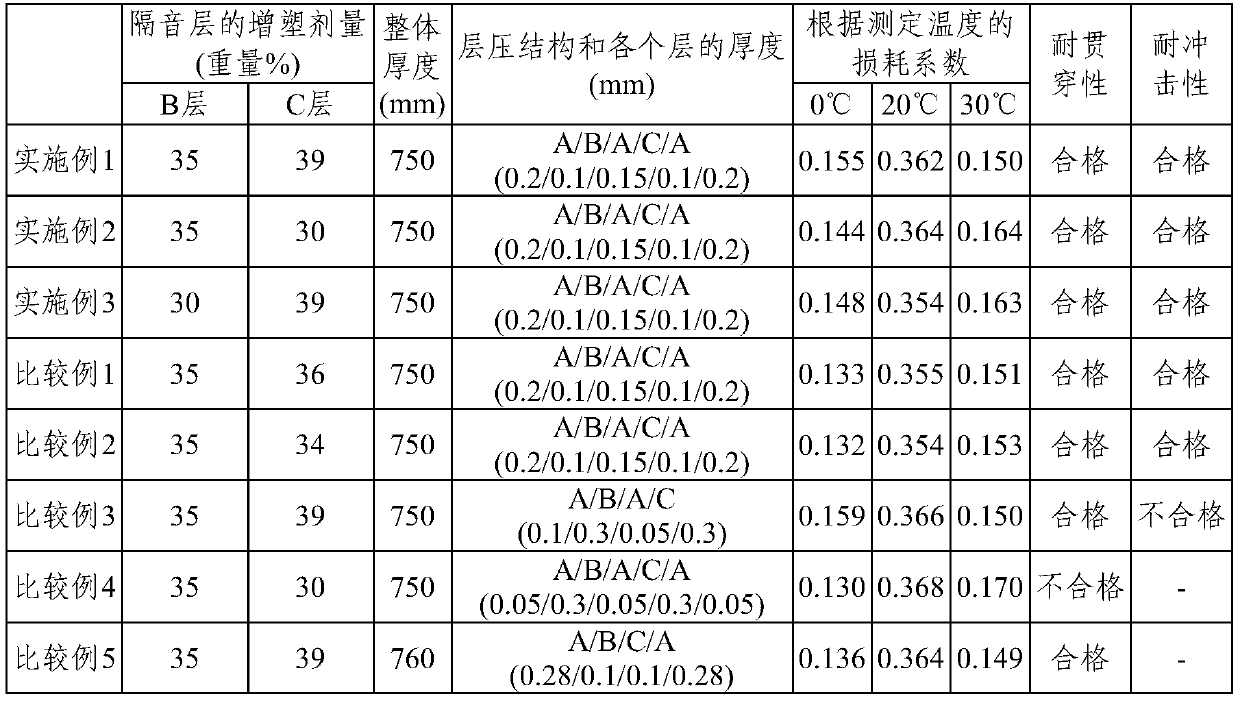

Embodiment 1

[0067] Embodiment 1: the preparation of multilayer polyvinyl acetal film

[0068] For the preparation of multilayer films, 3 twin-screw extruders (manufacturing company: SM Platek Corporation) were used. The first extruder is used to prepare the A layer, the second extruder is used to prepare the B layer, and the third extruder is used to prepare the C layer, and the resin composition of the following layers is dropped into each extruder and Extrusion was performed at 180°C.

[0069] A layer: based on the total weight of the composition, including 73% by weight of the first polyvinyl acetal resin and 27% by weight of triethylene glycol-bis-2-ethylhexanoate (3G8) as a plasticizer Compositions.

[0070] Layer B: a composition comprising 65% by weight of the second polyvinyl acetal resin and 35% by weight of 3G8 as a plasticizer, based on the total weight of the composition.

[0071] Layer C: a composition comprising 61% by weight of the second polyvinyl acetal resin and 39% b...

Embodiment 2

[0073] Embodiment 2: the preparation of multilayer polyvinyl acetal film

[0074] A multilayer film was prepared in the same manner as in Example 1 except for using the resin composition of each layer described below.

[0075] Layer A: a composition comprising 73% by weight of the first polyvinyl acetal resin and 27% by weight of 3G8 as a plasticizer, based on the total weight of the composition.

[0076] Layer B: a composition comprising 65% by weight of the second polyvinyl acetal resin and 35% by weight of 3G8 as a plasticizer, based on the total weight of the composition.

[0077] Layer C: a composition comprising 70% by weight of the second polyvinyl acetal resin and 30% by weight of 3G8 as a plasticizer, based on the total weight of the composition.

Embodiment 3

[0078] Embodiment 3: the preparation of multilayer polyvinyl acetal film

[0079] A multilayer film was prepared in the same manner as in Example 1 except for using the resin composition of each layer described below.

[0080] Layer A: a composition comprising 73% by weight of the first polyvinyl acetal resin and 27% by weight of 3G8 as a plasticizer, based on the total weight of the composition.

[0081] Layer B: a composition comprising 70% by weight of the second polyvinyl acetal resin and 30% by weight of 3G8 as a plasticizer, based on the total weight of the composition.

[0082] Layer C: a composition comprising 61% by weight of the second polyvinyl acetal resin and 39% by weight of 3G8 as a plasticizer, based on the total weight of the composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com